Crawling mechanism for damage ultrasonic detection of steel structure

A steel structure, ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, measuring devices, etc., can solve problems such as difficult manual detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

[0029] Concrete embodiment is as follows:

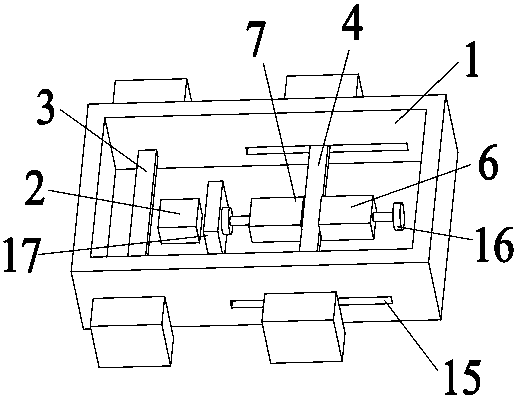

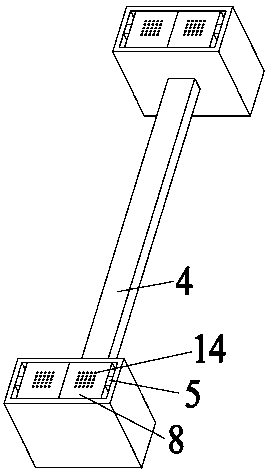

[0030] There are two final positions of the rear leg 4, one is the first position, the position where the rear leg 4 and the front leg 3 differ the farthest, and the second is the second position, the position where the rear leg 4 and the front leg 3 are the shortest.

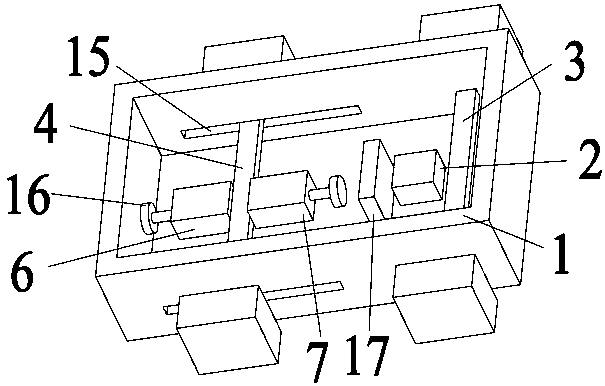

[0031] Such as figure 1 As shown, the structure diagram of the crawling device in the first position, a crawling device for ultrasonic detection of steel structure damage, including a first box 1 and a pair of legs, the first box 1 is provided with an ultrasonic detector 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com