Liquid weighing device

A technology for weighing devices and liquids, which is used in measurement devices, weighing, weighing devices for materials with special properties/forms, etc. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

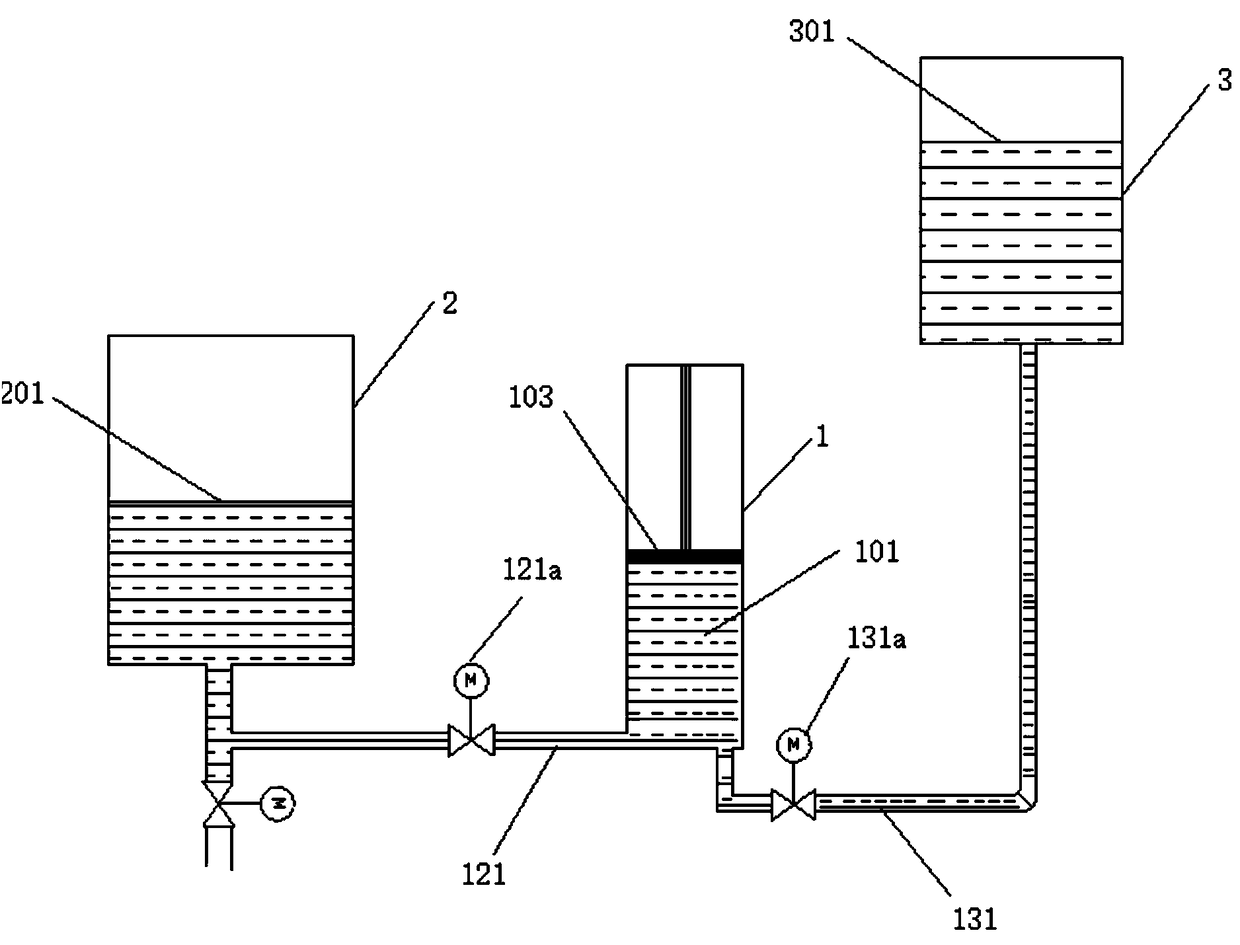

[0033] See figure 1 , figure 1 It is a schematic structural diagram of the liquid weighing device provided in Example 1 of the present invention. The liquid weighing device in this embodiment includes a tank body 1, a connecting pipe, a liquid scale 2 and a liquid storage tank 3;

[0034] The tank body 1 is a piston cylinder with a uniform cross-section. The inside of the tank body 1 is provided with a fluid replacement chamber 101 and a piston 103 that slides and fits in the tank body and is used to change the volume of the fluid replacement chamber. The lower part of the tank body 1 is designed as a fluid replacement chamber 101. The cavity 101 can also be arranged on the upper part of the tank body 1 .

[0035] The connecting pipe includes a first weighing tube 121 and a first liquid storage tube 131. The liquid replacement chamber 101 communicates with the liquid scale 2 through the first weighing tube 121, and the liquid replacement chamber 101 also communicates with th...

Embodiment 2

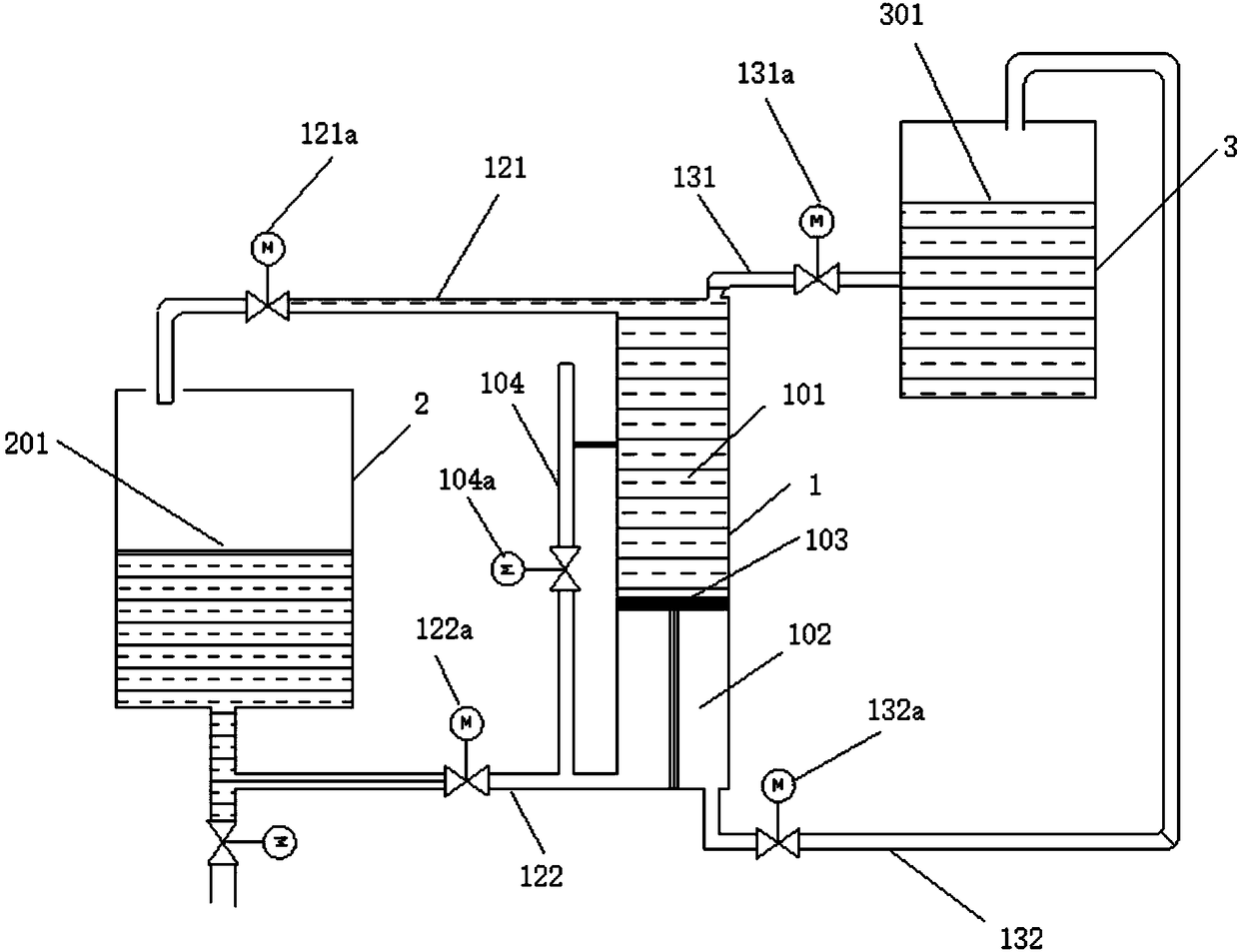

[0046] See figure 2 , figure 2 Schematic diagram of the structure of the liquid weighing device provided by Embodiment 2 of the present invention. The liquid weighing device provided in Embodiment 2 of the present invention includes a tank body 1, a connecting pipe, a liquid scale 2, and a liquid storage tank 3; the inside of the tank body 1 is provided with a liquid replenishment chamber 101, which is slidably fitted in the liquid replenishment chamber and used to change the liquid replenishment chamber. The piston 103 of the cavity volume; the connecting pipe includes the first weighing tube 121 and the first liquid storage pipe 131, and some other connecting pipes have been added; the difference between the liquid weighing device in this embodiment and the embodiment 1 is that, The second weighing tube 122, the second liquid storage tube 132 and the buckle cavity 102 are added (note that the buckle cavity 102 at this time is the liquid replacement cavity 101, and the two...

Embodiment 3

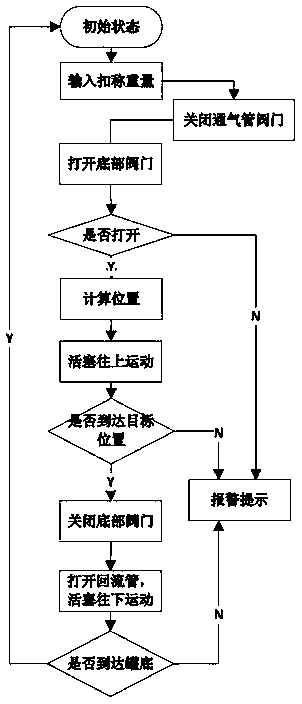

[0051] See image 3 , the liquid weighing device in this embodiment includes a tank body 1, a piston, a connecting pipe and a vent pipe; the inside of the tank body 1 is provided with a liquid replenishment chamber 101 and a piston 103 that slides and fits in the liquid replenishment chamber and is used to change the volume of the liquid replenishment chamber The connecting pipe includes the first weighing tube 121 and the first liquid storage tube 131, and it also increases some technical structures on the basis of the scheme of embodiment 1; for example: it increases the second weighing tube 122 and the second storage tube The liquid pipe 132, the air pipe 104, and the weighing cavity 102; the air pipe is connected to the weighing chamber; the air pipe is provided with a valve (namely, the air pipe valve 104a). in image 3 The medium replenishment chamber 101 and the weighing chamber 102 are two chambers on both sides of the piston 103 .

[0052] In the initial state, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com