A sensor fault diagnosis method

A sensor failure and sensor technology, applied in instruments and other directions, can solve problems such as hidden dangers of operator and equipment safety, sensor detection device diagnosis, etc., and achieve the effects of stable and reliable safe operation, improved coverage, and improved scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

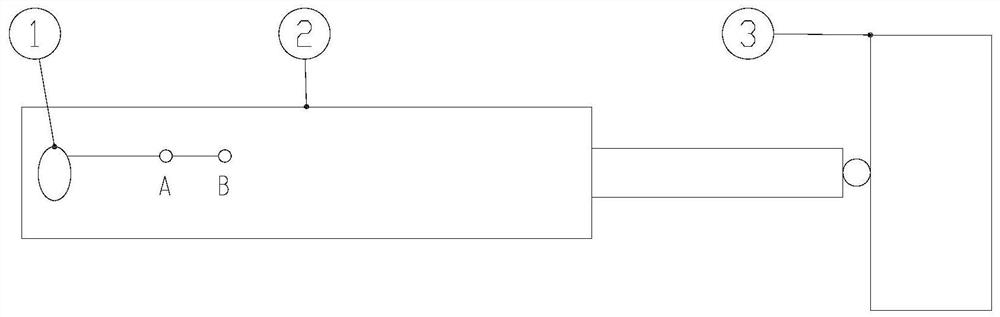

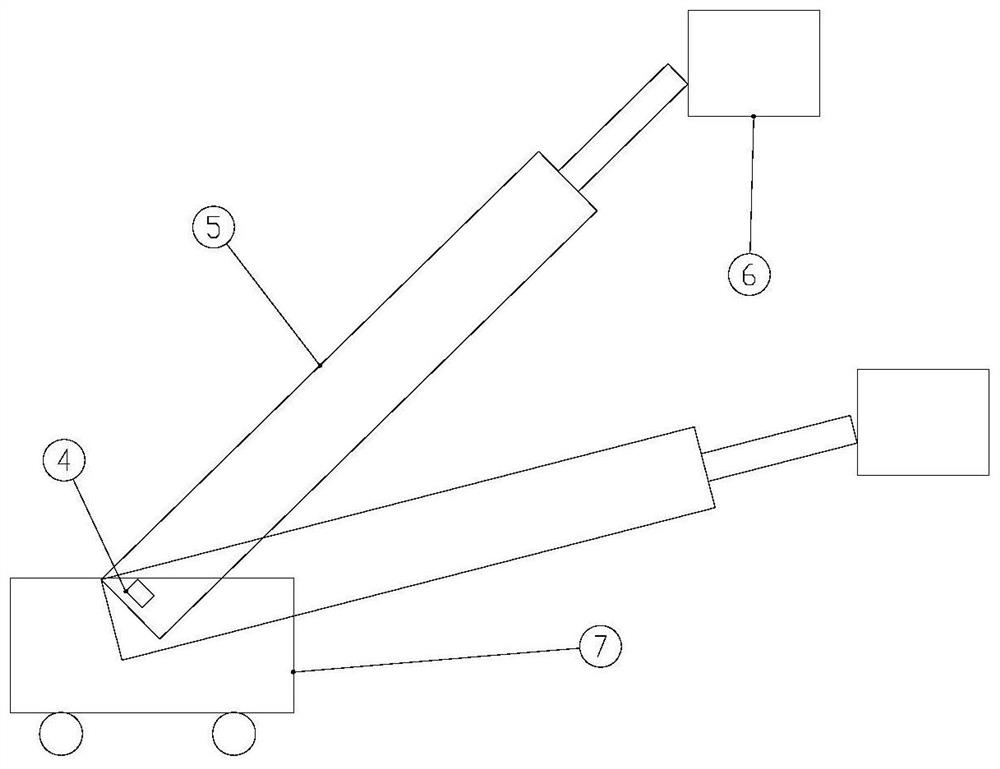

Image

Examples

Embodiment 3

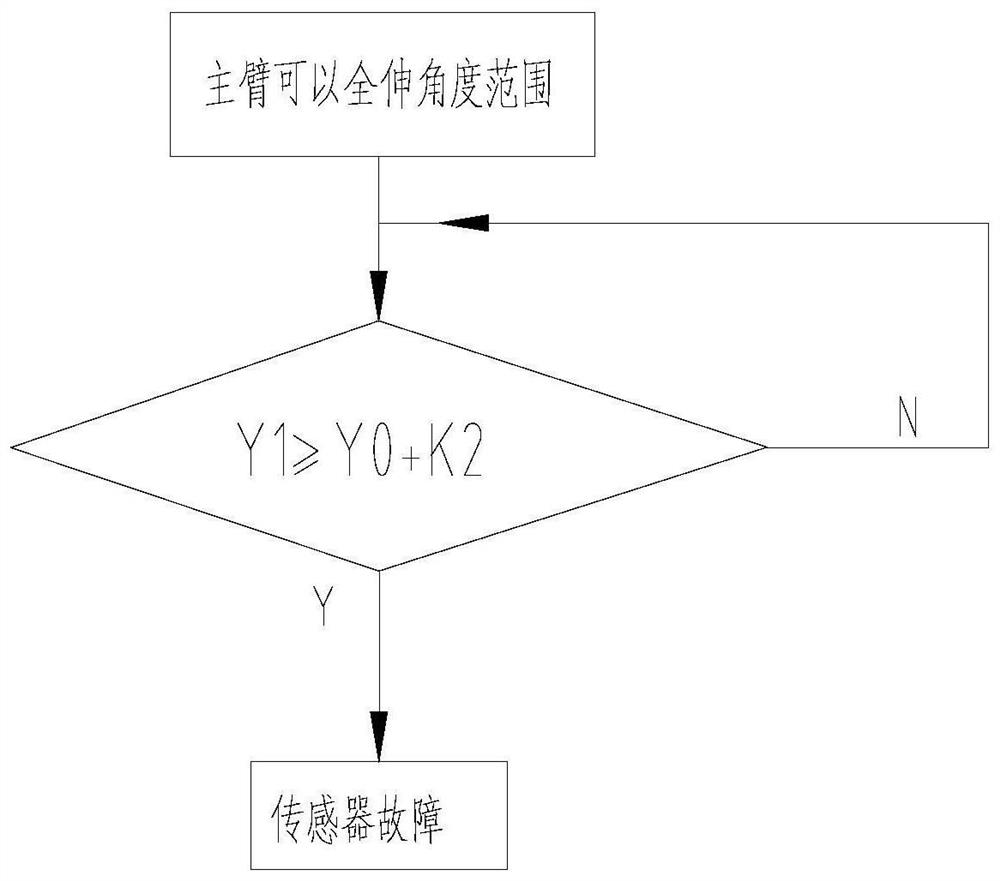

[0054] Embodiment 3 of the present invention is: a sensor fault judgment method, which is different from Embodiment 1 in that: the sensor uses CAN communication to transmit data, therefore, the following method can also be used in the process of fault judgment of this type of sensor Diagnosis: On the basis of monitoring the heartbeat of CAN communication, use the communication function of the controller to perform real-time data diagnosis to expand the scope of diagnosis. If the return value of the communication function is not the normal value specified by the function (usually, the function return value 0 or 1 is the normal state, and the normal value can be specified differently according to different controllers), the communication or value of the sensor is also considered If there is an abnormality, make a sensor failure judgment.

[0055] The minimum current referred to in the present invention is the lowest current value required by the mechanism to complete the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com