Rotatable orifice closure

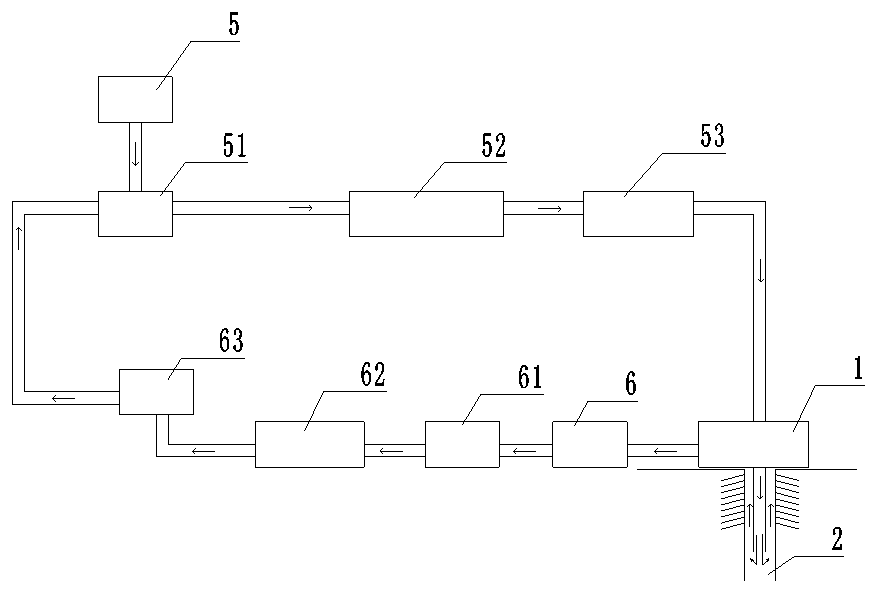

A closed orifice rotary technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as complicated procedures, affecting grouting effect and quality, and achieve reduced construction costs and convenient construction , Guarantee the effect of grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

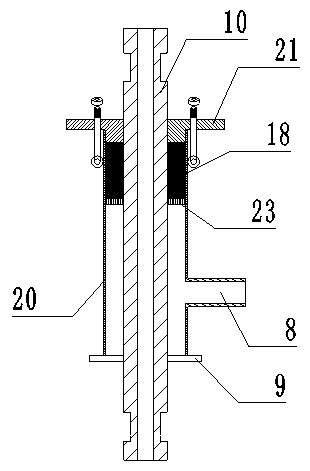

[0022] Example 1, such as image 3 As shown, a rotatable orifice closure is improved on the basis of the existing orifice closure. The skeleton oil seal is used to replace the rubber ball for sealing, and the rolling bearing is used to make the grouting rod rotate while grouting, effectively preventing buried drill. Specific as image 3 As shown, it includes a casing 20, a grouting rod 10, an upper gland 21, a skeleton oil seal 11, a snap ring 12, a rolling bearing 13, a rotating power 30, and a control system. The inner wall of the casing is fixed with a gasket 23, and the skeleton oil is sealed on the top of the gasket. On the surface, the inner wall of the shell above the skeleton oil seal is designed with a snap ring groove that matches the snap ring. The rolling bearing is fixed above the snap ring. The side of the shell is designed with a slurry return port 8 that communicates with the center hole. Below, the slurry return port communicates with the pressure gauge 6, a...

Embodiment 2

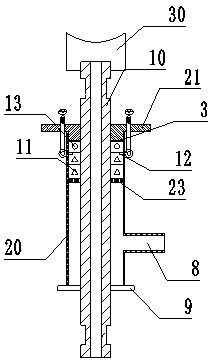

[0023] Example 2, such as Figure 4 As shown, a rotatable orifice closure device includes a casing 20, a grouting rod 10, an upper gland 21, a skeleton oil seal 11, a snap ring 12, a rolling bearing 13, a rotating power 30, and a control system. The casing is divided into an upper casing Two parts 201 and lower shell 202 are connected between the upper shell 201 and the lower shell 202 by the lower cover 7, and the two are closed and connected, and a skeleton oil seal is fixed under the lower cover to effectively prevent the slurry below from entering the upper shell Inside. The lower shell mainly plays the role of slurry return, and the side of the lower shell is designed with a slurry return port 8 communicating with the central hole, and the lowermost end of the lower shell is a flange 9. The upper shell is mainly used to seal the grouting rod and provide the function of rotation. The upper shell is sequentially equipped with a gasket 3, a rolling bearing 13, a snap ring 1...

Embodiment 3

[0024] Example 3, such as Figure 5 As shown, a rotatable orifice closure device includes a casing 20, a grouting rod 10, an upper gland 21, a skeleton oil seal 11, a snap ring 12, a rolling bearing 13, a rotating power 30, and a control system. The casing is divided into an upper casing Two parts 201 and lower shell 202 are connected between the upper shell 201 and the lower shell 202 by the lower cover 7, and the two are closed and connected, and a skeleton oil seal is fixed under the lower cover to effectively prevent the slurry below from entering the upper shell Inside. The lower shell mainly plays the role of slurry return, and the side of the lower shell is designed with a slurry return port 8 communicating with the central hole, and the lowermost end of the lower shell is a flange 9. The upper shell is mainly used to seal the grouting rod and provide the function of rotation. The upper shell is sequentially equipped with gasket 3, rolling bearing, snap ring, bearing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com