Prestressed super concrete pipe with pile wall-protecting type small composite anti-slide pile structure

A technology of concrete pipe piles and high-strength concrete, which is applied in the fields of infrastructure engineering, construction, excavation, etc., can solve the problems of high engineering cost, achieve fast construction, short construction period, and improve the strength of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

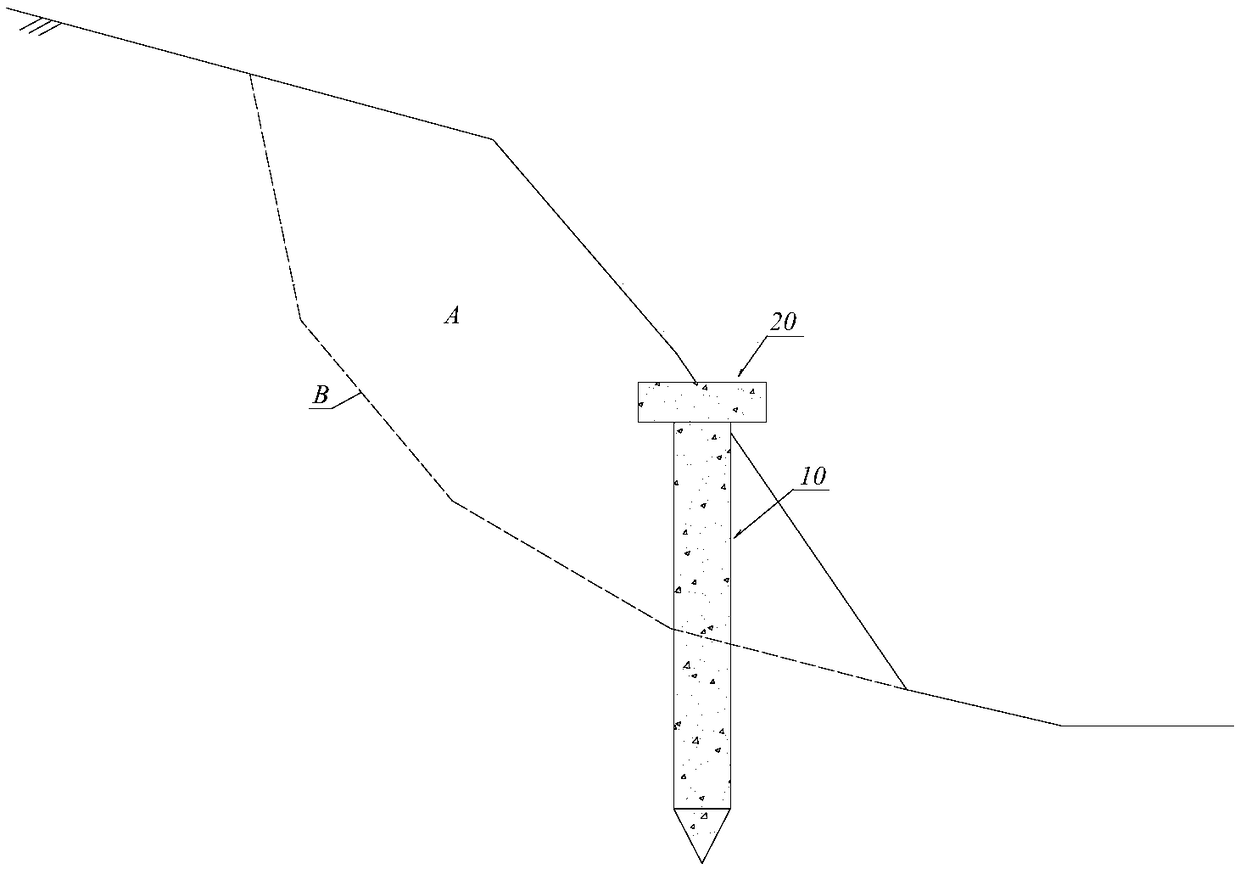

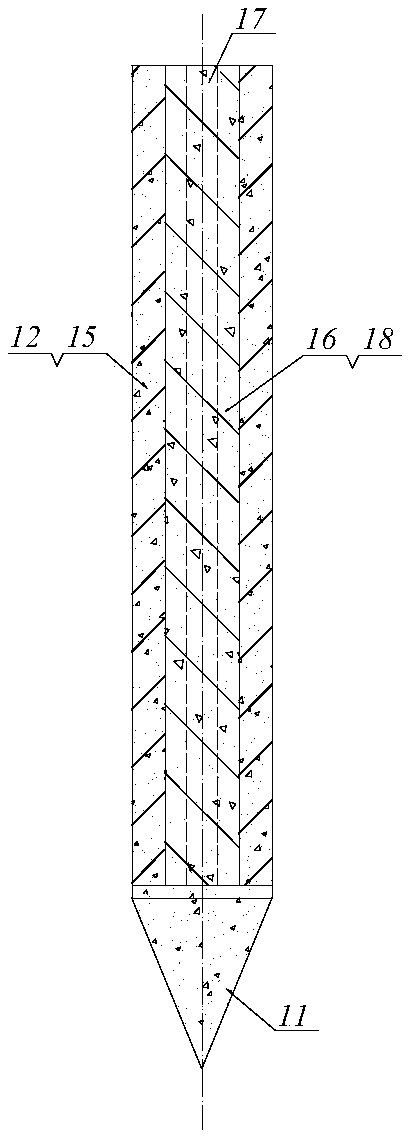

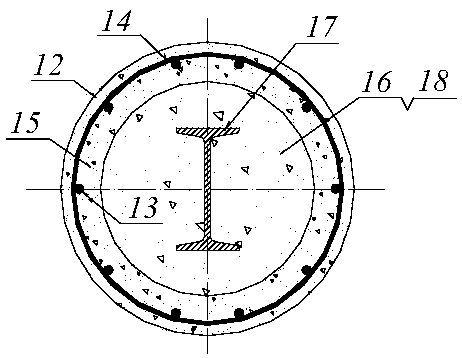

[0027] refer to figure 1 , figure 2 and image 3 , the small combined anti-slide pile structure driven into prestressed super-strong concrete pipe pile wall protection of the present invention includes single anti-slide piles 10 arranged at intervals in the sliding body A, and the lower part of the pile body passes through the sliding surface B and enters the bearing layer , which is characterized in that: the single anti-slide pile 10 is composed of a prestressed prestressed high-strength concrete pipe pile 12 and a reinforced concrete inner core 16. The lower part of the prestressed high-strength concrete pipe pile 12 shrinks radially to form a pile tip 11, and the pile body is driven into the ground; the reinforced concrete inner core 16 is poured in the inner hole of the prestressed high-strength concrete pipe pile 12, and consolidated into one....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com