A method of installation and construction of steel box arch rib buckle hanging method

A construction method and technology for steel box arches, which are applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of the change of the steel arch rib axis, the inconvenience of analyzing the favorable or unfavorable stress of the arch rib, and the uncertainty, etc. To achieve the effect of guaranteed connection strength, fast connection and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

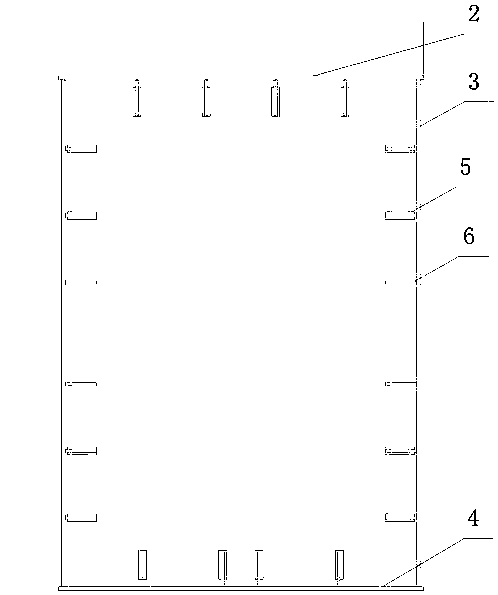

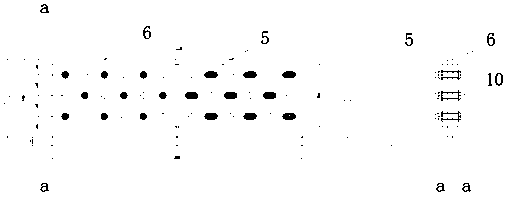

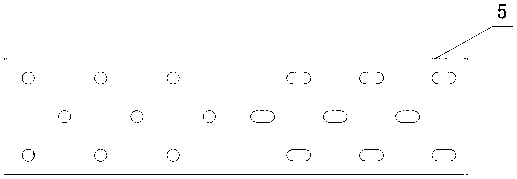

[0022] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like Figure 1 to Figure 10 Shown: An installation and construction method of a steel box arch rib buckle hanging method, which is divided into three stages, namely the lifting and position adjustment stage, the buckle conversion stage and the secondary tensioning stage,

[0023] The construction process of the lifting and position adjustment stage is as follows: lift the installation arch rib 11 of a single steel box to the installation position by the first crane 12 and the second crane 13, and use the jack, the code plate 20, the lateral wind cable, The first crane 12 and the second crane 13 cooperate to adjust the posture of the arch rib. In order to facilitate the adjustment of the posture of the installation arch rib 11, the relationship between the installation arch rib 11 and the target arch rib 15 installed in the previous section is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com