Production method of silk-screen gum

A production method and technology with wires, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of high labor intensity of workers, lower product quality, and low production efficiency, so as to reduce labor intensity of workers and improve product quality. The effect of high quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

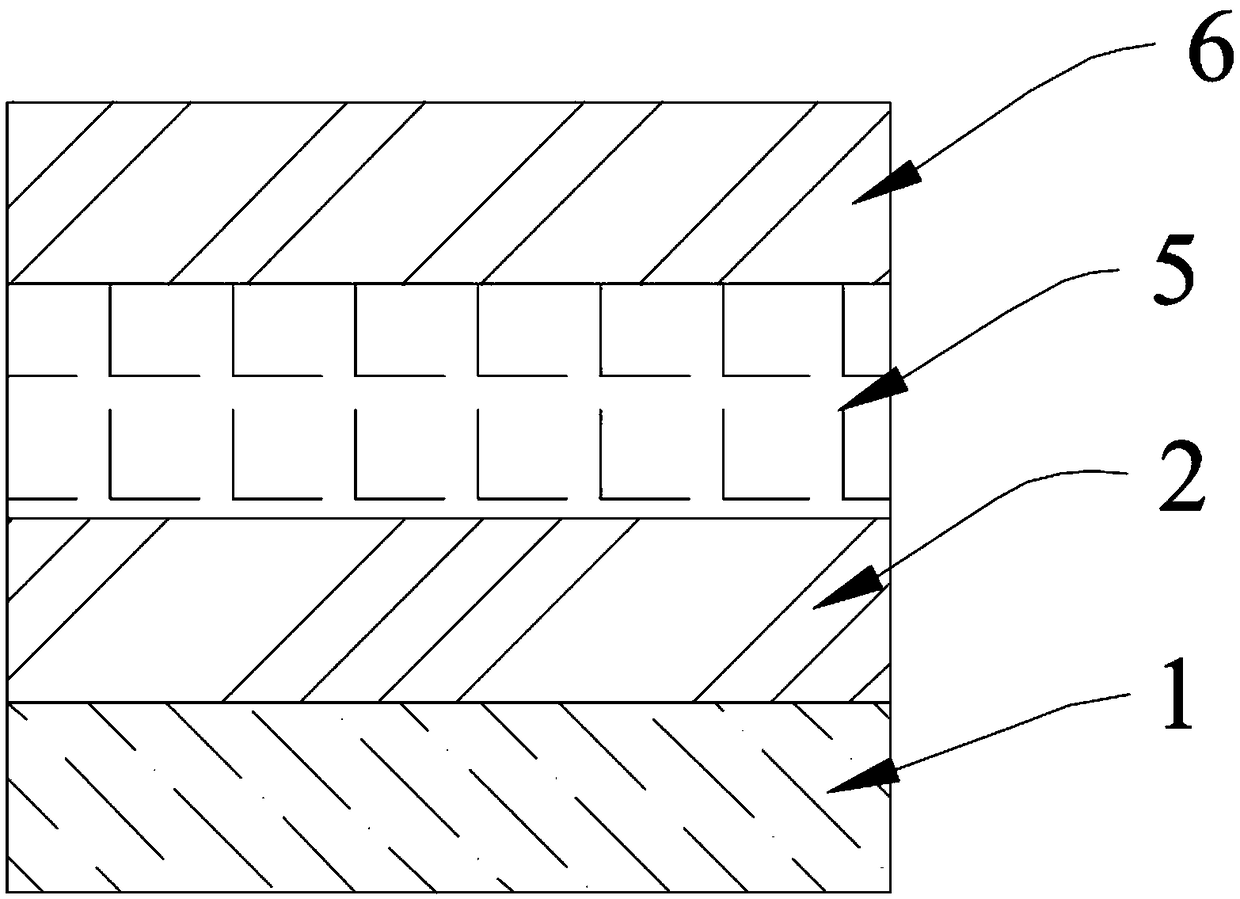

[0048] Please refer to figure 1 As shown, it is a structural schematic diagram of a screen printing adhesive in the embodiment. The present embodiment provides a kind of back glue with screen printing, and it comprises double-sided coated PET film 1, double-sided adhesive tape 2, release film 5 and black horse-drawn glue 6, wherein black horse-drawn glue 6, double-sided tape 2, double-sided glue The side-coated PET film 1 and the release film 5 are bonded sequentially, wherein the double-sided coated PET film 1 is printed with silk screen.

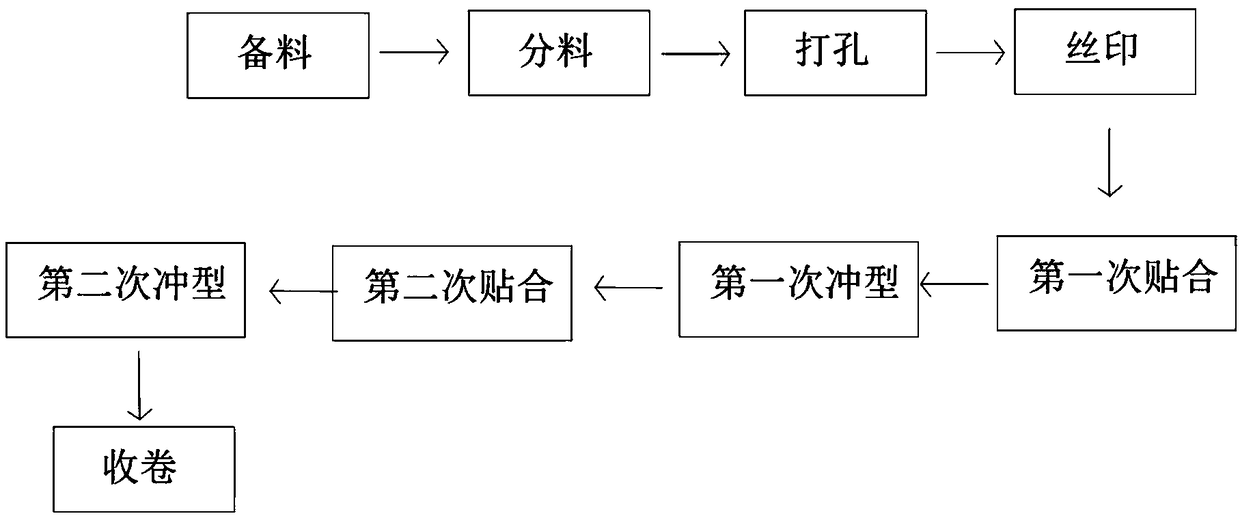

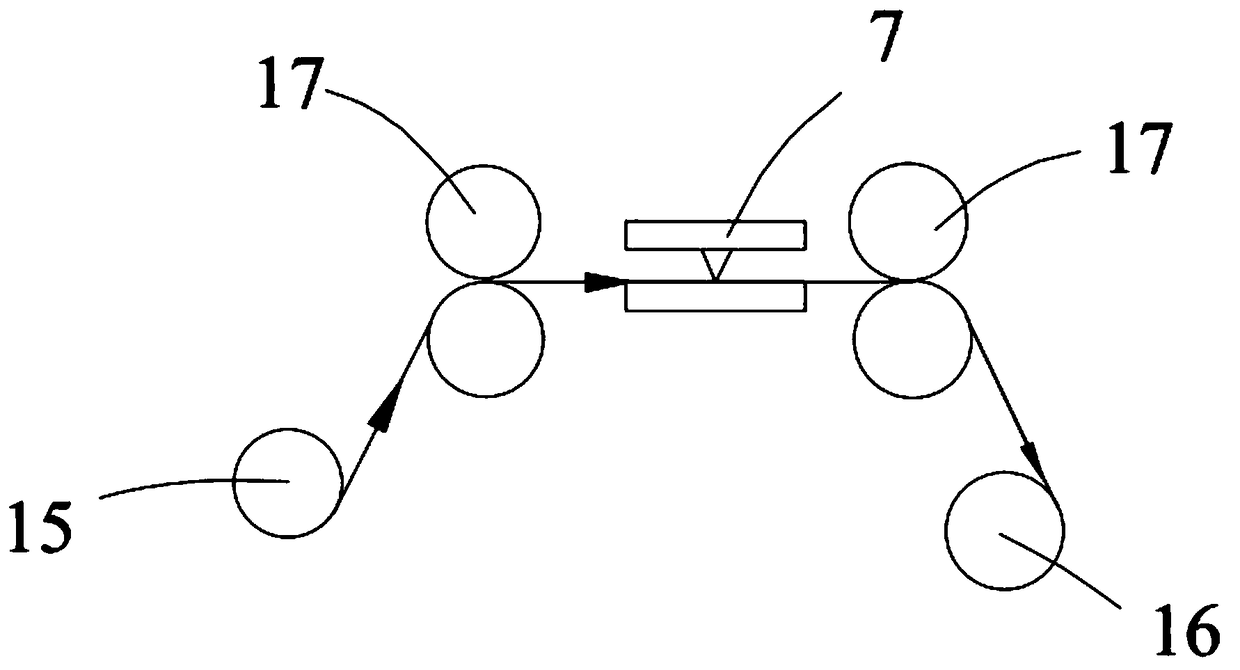

[0049] Please refer to Figures 2 to 4 Shown are the production steps of the production method with silk screen adhesive in the embodiment, the material flow diagram of step three of the production method with silk screen adhesive, and the material flow diagram of steps five to nine of the production method with silk screen adhesive.

[0050] This embodiment provides a production method with silk screen adhesive. The production method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com