A kind of preparation method of modified graphene oxide composite polypropylene packaging film

A graphene composite and packaging film technology, applied in the field of packaging materials, can solve the problems of difficulty in graphene oxide, poor gas barrier properties, and difficulty in uniform dispersion of graphene oxide, so as to improve mechanical properties and heat resistance, and improve the interface. Compatibility, gas barrier performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

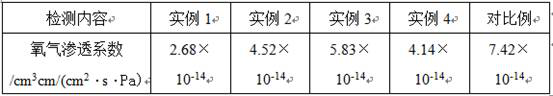

Examples

example 1

[0020]Mix graphene oxide and water into a beaker at a mass ratio of 1:20, stir and mix with a stirrer at a speed of 500r / min for 60 minutes, and then add a nonionic surfactant of 0.4 times the mass of graphene oxide to the beaker, Then, at a temperature of 56°C and an ultrasonic frequency of 60 kHz, constant temperature ultrasonic treatment was performed for 2 hours to obtain a graphene oxide dispersion; vinylbenzyl octadecyl dimethyl ammonium chloride and graphite oxide were mixed in a mass ratio of 1:12 The olefin dispersion was mixed and poured into a hydrothermal reaction kettle. Under the conditions of temperature of 160°C, pressure of 1.2MPa, and rotation speed of 600r / min, after hydrothermal stirring and reaction for 5 hours, the hydrothermal reaction kettle was opened, and the pressure was released to normal pressure. Suction filter the material in the hydrothermal reaction kettle to obtain a filter cake, and wash the filter cake with deionized water for 5 times, then t...

example 2

[0022] In parts by weight, successively take 20 parts of styrene, 60 parts of graphene oxide, 5 parts of initiator, 3 parts of emulsifier, 5 parts of electrolyte, and 300 parts of water, first add graphene oxide and emulsifier into water, and stir Stir and mix at a speed of 600r / min for 60min to obtain a water emulsion, then transfer the water emulsion into the reactor, and feed an inert gas into the reactor at a rate of 600mL / min, and under the protection of the inert gas, add Styrene, under the condition of ultrasonic frequency of 60kHz, after ultrasonic dispersion for 60min, then add the initiator, continue under the state of inert gas protection, at the temperature of 85°C, the stirring speed of 800r / min, after constant temperature stirring reaction for 8h, Add an electrolyte to demulsify, and then filter to obtain a filter residue, wash the filter residue 6 times with deionized water, and then vacuum freeze-dry the washed filter residue to obtain modified graphene oxide; i...

example 3

[0024] In parts by weight, take 30 parts of graphene oxide, 80 parts of polypropylene, and 400 parts of xylene in sequence, first pour graphene oxide and xylene into a mixer, and ultrasonically disperse them for 2 hours at a frequency of 60 kHz, then add poly Propylene, at a temperature of 145°C and a rotational speed of 800r / min, heat and stir to dissolve for 2 hours, slowly add the material in the mixer to absolute ethanol at a rate of 10g / min, and wait until the material in the mixer is added dropwise After completion, filter to obtain a precipitate, and then freeze-dry the obtained precipitate in a vacuum, and then heat-press to form a film at a temperature of 200° C. and a pressure of 15 MPa to obtain a modified graphene oxide composite polypropylene packaging film. The nonionic surfactant is octylphenol polyoxyethylene ether. The initiator is ammonium persulfate. The emulsifier is emulsifier OP-10. The electrolyte is magnesium sulfate. The inert gas is nitrogen. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com