Process for recovering ethane from natural gas

A natural gas and process technology, which is applied in the field of ethane recovery from natural gas, can solve the problems of easy freezing and blockage and the failure of normal production of the device, and achieve the effect of reducing engineering wages and reducing the energy consumption of device operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

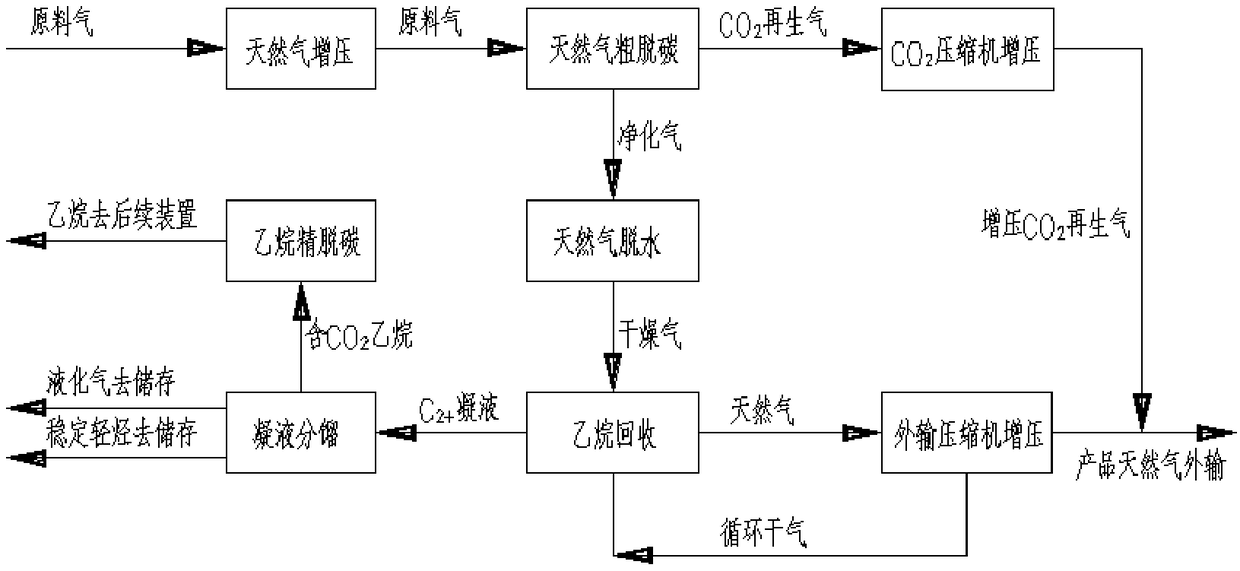

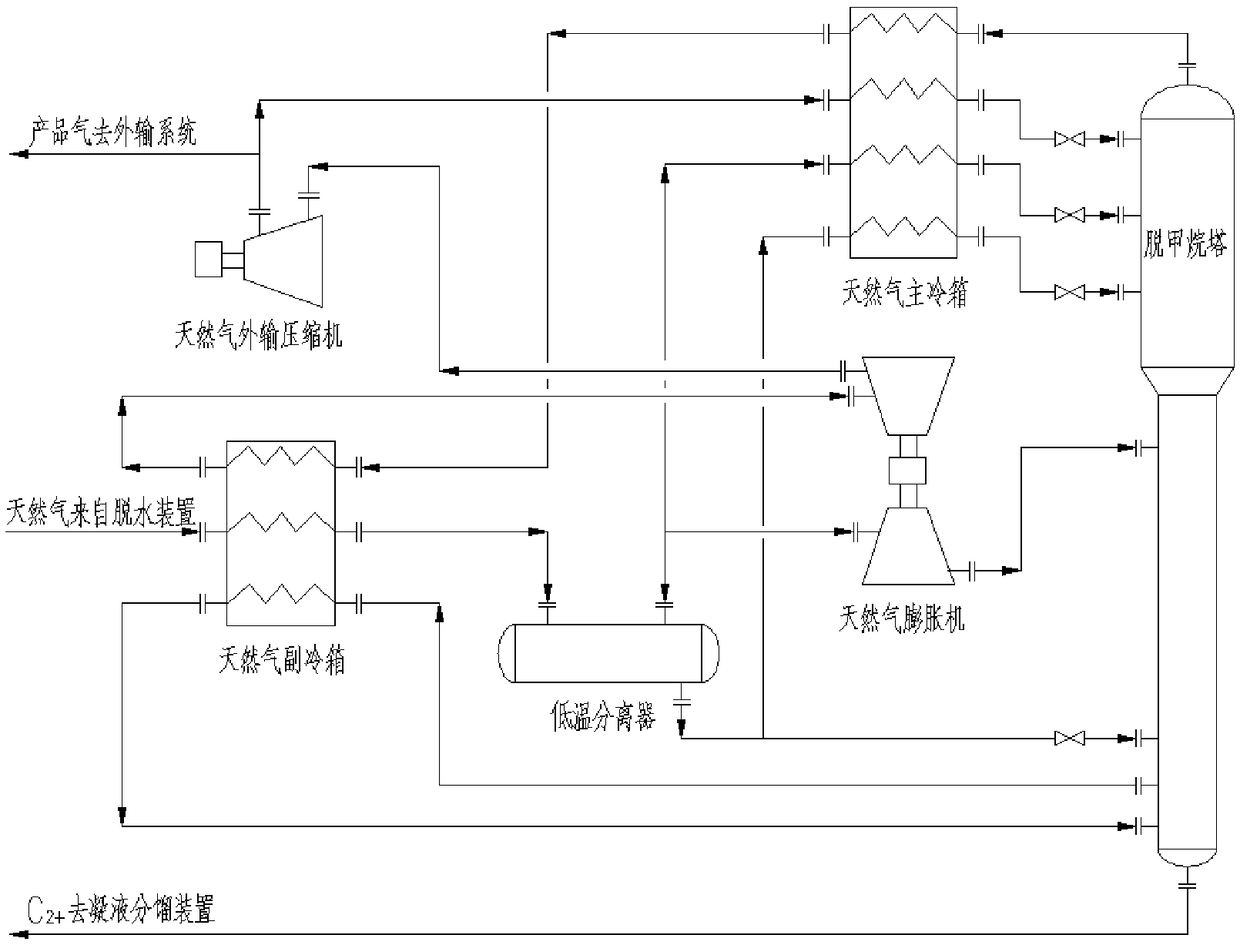

[0035] Such as figure 1 Shown, the present invention provides a kind of process of recovering ethane from natural gas, comprises the following steps:

[0036] 1) Natural gas pressurization: The natural gas booster device is designed according to the incoming pressure of the feed gas and the output pressure requirements (usually when the feed gas pressure is > 2.5 times the operating pressure of the demethanizer (0.9-3.0MPa), no pressurization is required ( Adjust according to specific circumstances));

[0037] 2) Crude decarbonization of natural gas: the natural gas obtained in step 1) is decarburized by alcohol amine method to obtain CO 2 Regenerated and purified gas (CO 2 Content≤1.2% (v / v)); CO in natural gas after decarbonization 2 ≤1.2% (v / v) (adjusted according to actual working conditions), natural gas decarbonization and ethane decarbonization devices share the solution regeneration system, reducing device investment and operating energy consumption.

[0038] 3)CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com