Cable maintenance lift truck

A lift truck and cable technology, applied in the direction of lifting devices, etc., can solve the problems of inconvenient movement, large space occupation, inconvenient operation, etc., and achieve the effects of improving maintenance efficiency, small space occupation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

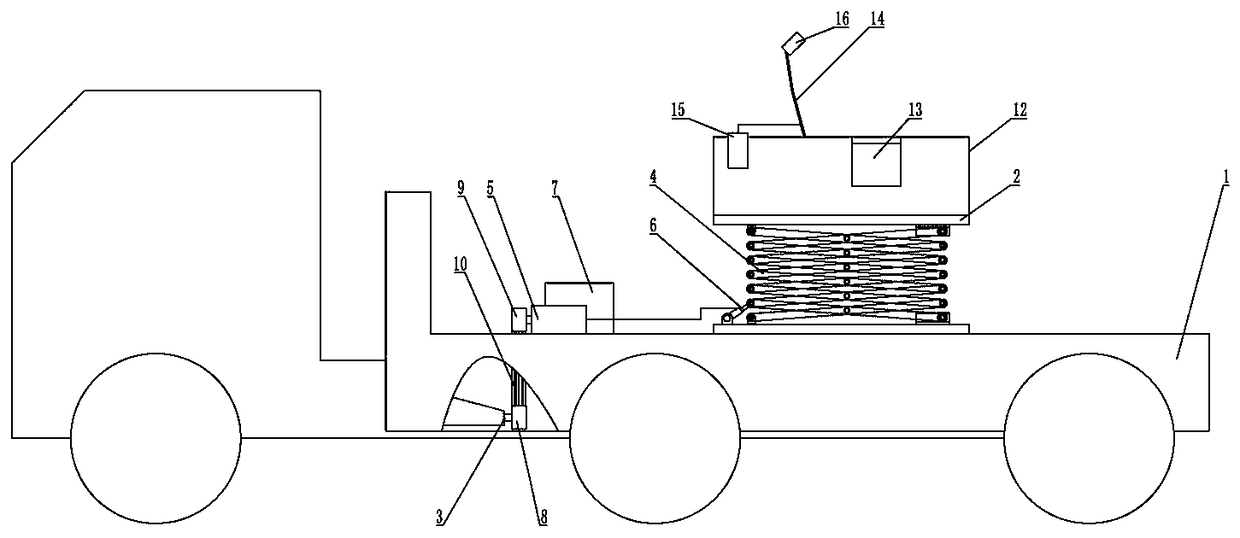

[0023] like figure 1 As shown, a kind of cable inspection and lifting vehicle comprises a truck 1, a lifting platform 2 installed on the truck 1, a lifting power device and a control system for driving the lifting platform 2 to move up and down, and the lifting power device is installed Between the lifting platform 2 and the truck 1, the control system controls and connects the lifting power device, and the power output shaft 3 of the truck 1 provides power to the lifting power device.

[0024] The lifting power device includes a scissor mechanism 4, a hydraulic oil pump 5, a hydraulic telescopic rod 6, a hydraulic oil valve and a hydraulic oil tank 7. The scissor mechanism 4 is composed of a plurality of scissor levers intersecting each other and hinged in the middle and at the end. The bottom ends of the first group of scissor rods at the bottom of the scissor mechanism 4 are hinged on the load-carrying platform of the truck 1, and the bottom ends of the second group of scis...

Embodiment 2

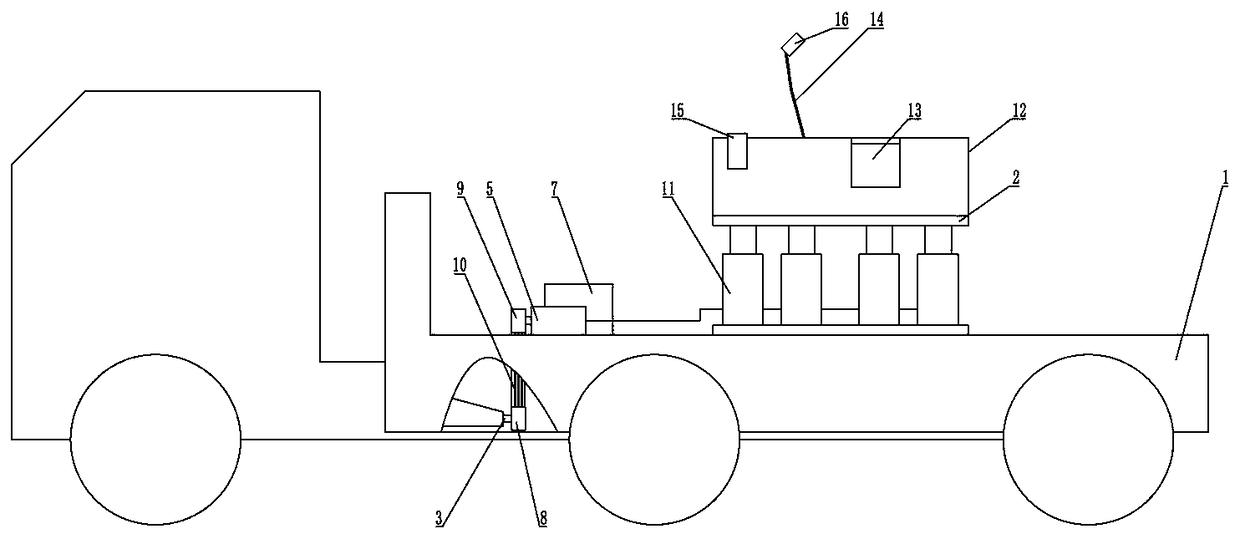

[0036] like figure 2 As shown, the difference from Embodiment 1 is that the lifting power device includes several hydraulic telescopic columns 11, hydraulic oil pumps 5, hydraulic oil valves and hydraulic oil tanks 7, and each of the hydraulic telescopic columns 11 is vertically installed on the truck 1 The bottom of the lifting platform 2 is installed on the top of each hydraulic telescopic column 11, the hydraulic oil pump 5 drives each hydraulic telescopic column 11 to expand and contract up and down through the hydraulic oil circuit, and the hydraulic oil valve is installed In the hydraulic oil circuit between the hydraulic oil pump 5 and the hydraulic telescopic column 11 , the hydraulic oil tank 7 provides hydraulic oil to the hydraulic oil pump 5 .

[0037] The hydraulic telescopic column 11 can replace the scissor mechanism and the hydraulic telescopic rod 6 to make the lifting platform 2 vertically lift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com