Regular fragment automatic sorting and guided bonding device and method

An automatic sorting and sorting device technology, applied in vibrating conveyors, transportation and packaging, conveyor objects, etc., can solve the problems of limited use range, large vibration and noise, low efficiency, etc., achieve simple and effective structure, reduce feeding The effect of the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

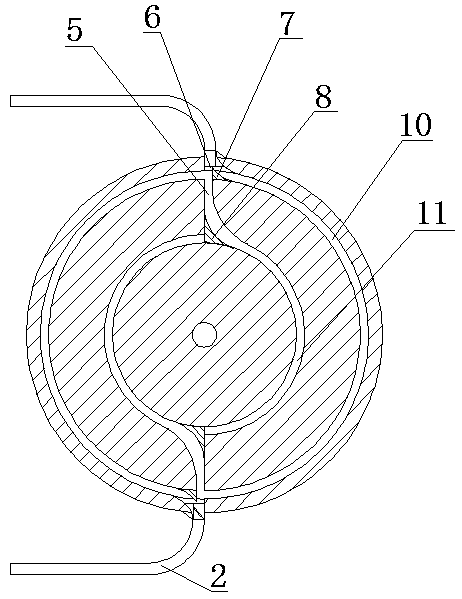

[0034] like Figure 1~5 As shown, an automatic sorting and guiding bonding device for regular fragments includes a driving mixing device 4, a storage sorting device 3, a guiding bonding pipeline 2 and an adjustment control system. The bottom of the storage sorting device 3 is provided with Two concentric inner grooves 11 and outer grooves 10, the middle of the bottom of the storage sorting device 3 is a round table, the driving mixing device 4 is set on the round table, and the guide bonding pipeline 2 is connected to the storage sorting device 3. The adjustment control system is used to adjust the rotation parameters of the driving mixing device 4, the rotation and movement parameters of the casing 1, and control the coupling relationship between the parameters.

[0035] Further, the storage sorting device 3 also includes a wedge-shaped guide block A8, a wedge-shaped guide block B7, a discharge outlet A5 and a discharge outlet B6, and the upper parts of the inner groove 11 an...

Embodiment 2

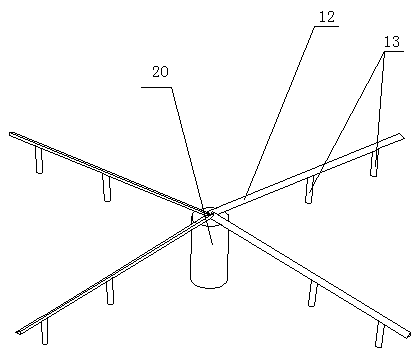

[0047] like Image 6 , this solution improves the storage sorting device 3 on the basis of Embodiment 1, and the storage sorting device 3 includes a wedge-shaped guide block B7, an outer groove 10 and a discharge outlet B6, and the discharge outlet B6 Connect the outside of the storage sorting device 3 with the outer groove 10. The upper part of the outer groove 10 is conical or arc-shaped, and the lower section is square. The wedge-shaped guide block B7 is arranged in the outer groove 10, which is provided with The arc side is tangent to one side of the square area at the bottom of the outer groove 10, and the height of the wedge-shaped guide block B7 does not exceed the height of the square groove.

[0048] Further, a thrust guide rod 13 is fixed at the lower end of each angular mixing rod 12 .

[0049] Further, only one guide bonding pipeline 2 is provided.

[0050] The difference between this embodiment and Embodiment 1 is that in this embodiment, only one storage groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com