A plastic bag heat sealing device

A heat-sealing device and plastic bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of power consumption, prone to wrinkles in the area, and affecting the quality of equipment production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

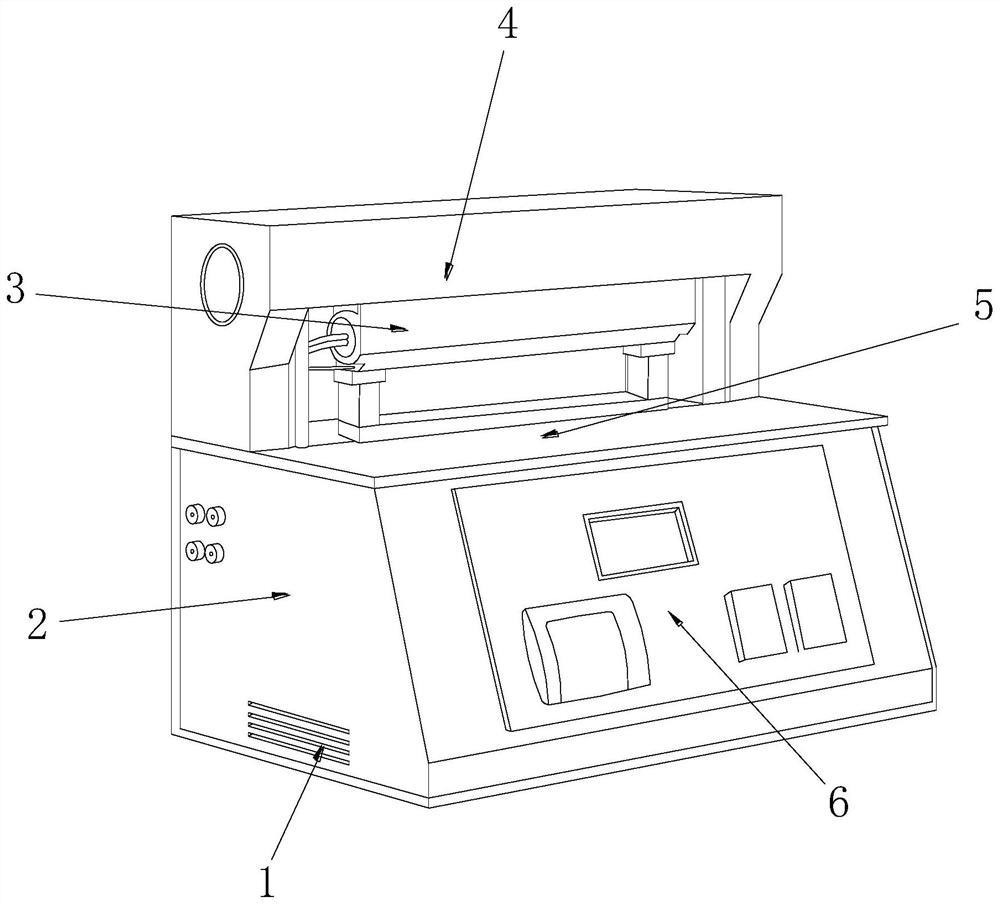

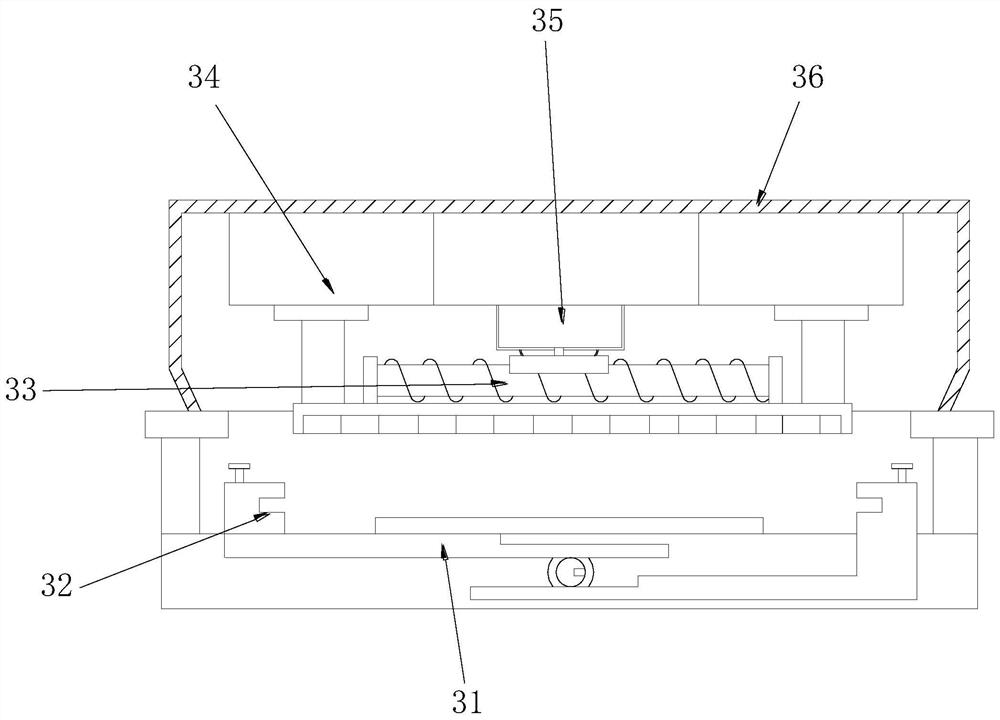

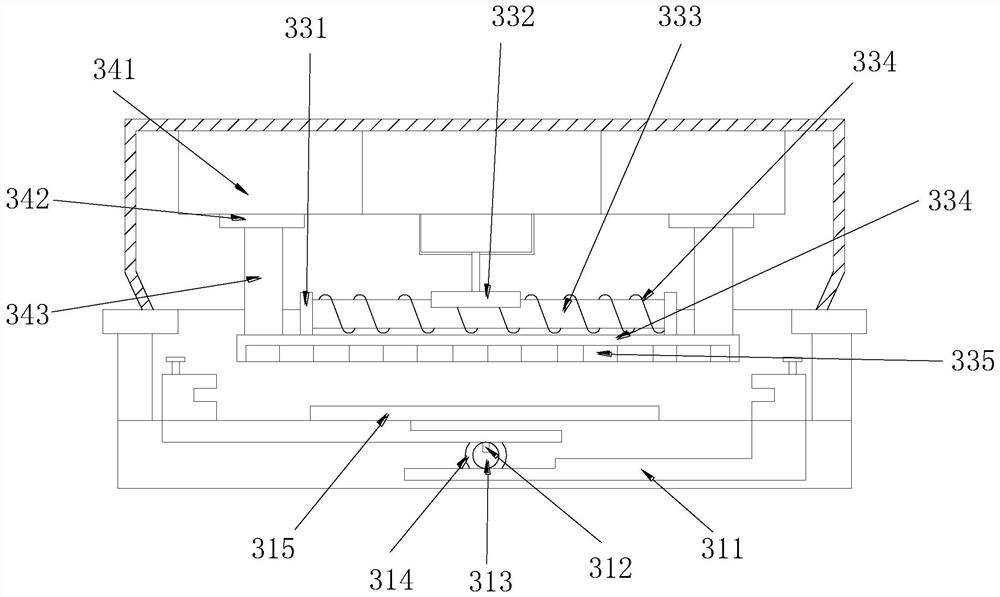

[0025] See Figure 1-Figure 7 , The present invention provides a plastic bag heat sealing device, the structure of which includes a heat dissipation port 1, a base 2, a heat sealer 3, a bracket 4, a workbench 5, and an operation panel 6. The heat dissipation port 1 is provided on the left side of the base 2. The heat sealer 3 is located directly above the workbench 5, and the heat sealer 3 is embedded and installed on the bracket 4, and the bottom end of the bracket 4 is opposite to the top end of the base 2. Welding, the operation panel 6 is arranged at the front end of the base 2 and the two are electrically connected. The workbench 5 is arranged at the top of the base 2, and the two are integrated structures. The heat sealer 3 includes a leveling mechanism 31. Plastic bag sealing and clamping mechanism 32, heating mechanism 33, telescopic assembly 34, power control assembly 35, housing 36, the top and left sides of the flattening mechanism 31 are provided with bottom ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com