A self-driving robot shifting manipulator

A technology for autonomous driving and robotics, applied in control devices, vehicle components, transportation and packaging, etc., can solve the problems of inaccurate control, complex structure, non-destructive installation, etc., and achieve simple motion principle, accurate shifting process, and external influence. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

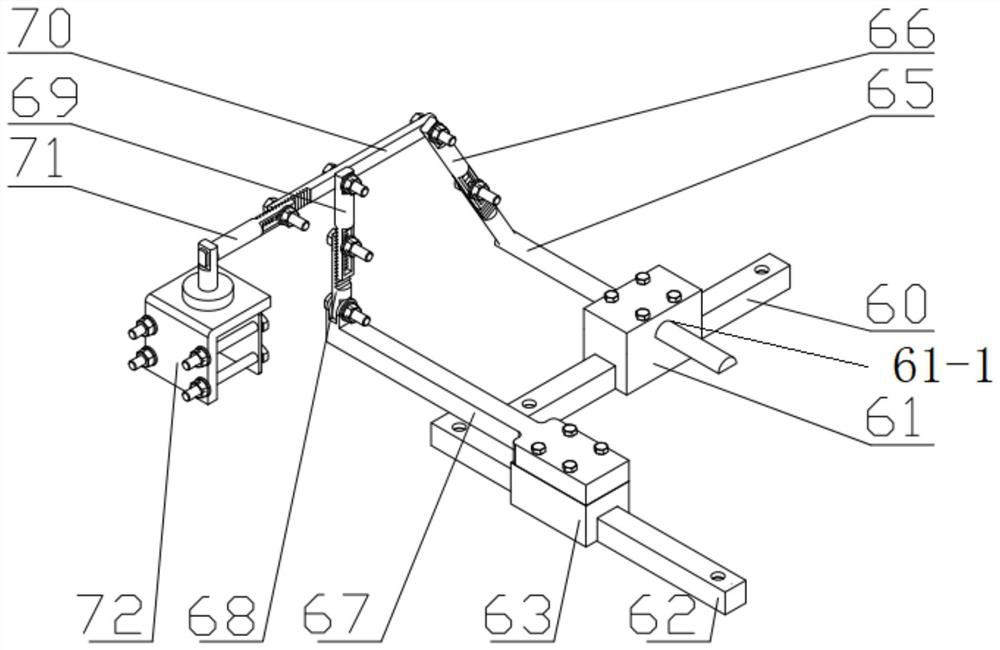

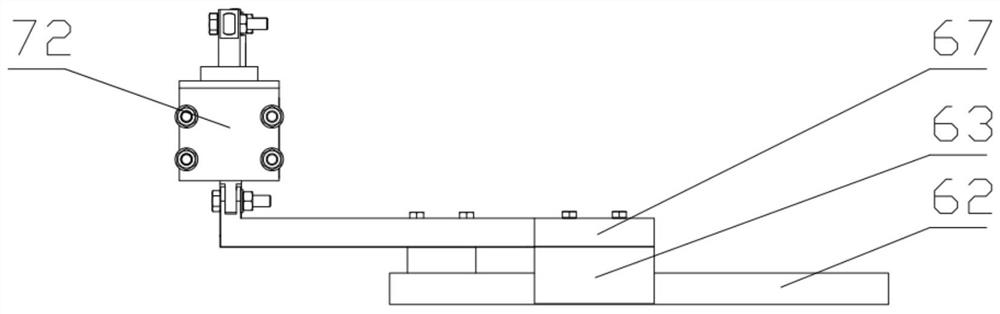

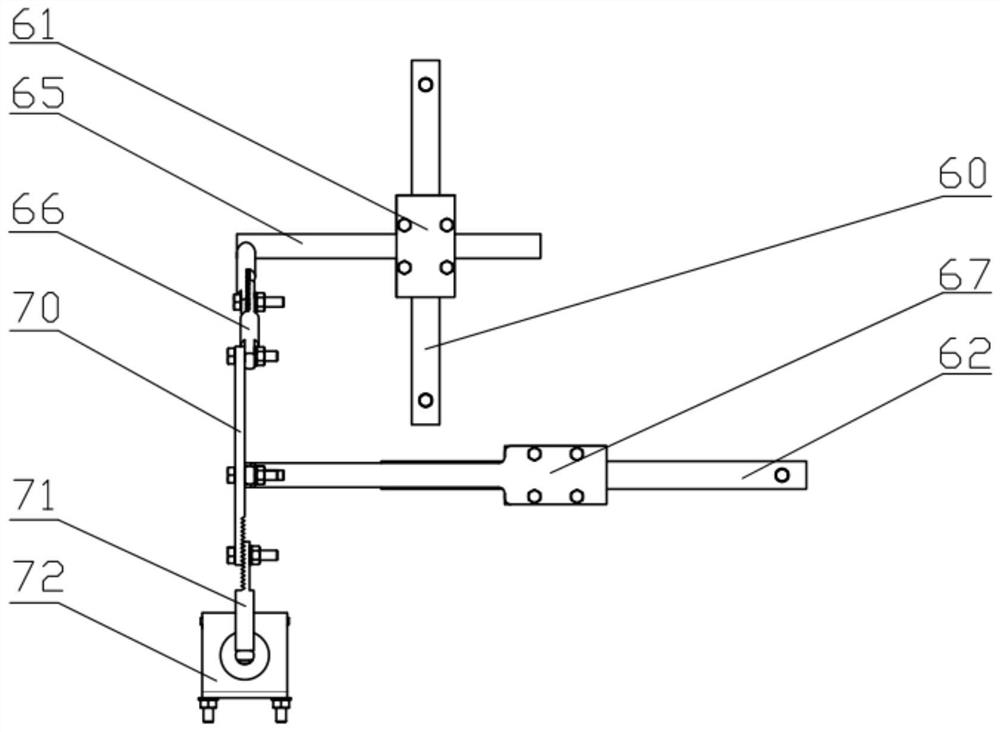

[0019] to combine figure 1 , a shift manipulator for an automatic driving robot of the present invention, comprising a first stepping motor, a first slider 61, a first slide rail 60, a first connecting rod 65, a second connecting rod 66, a first swing rod 70, Hand 72, the second stepping motor, the second slide block 63, the second slide rail 62, the third connecting rod 67, the fourth connecting rod 68; the first stepping motor, the second stepping motor, the first The slide rail 60 and the second slide rail 62 are all fixed on the upper end of the casing 1; the first stepping motor is connected with the first slide block 61; the first slide block 61 is driven to move back and forth along the first slide rail 60; A chute 61-1 is provided in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com