Mode-based intelligent control method for position-limited flexible joint robot

A technology of flexible joints and intelligent control, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., and can solve problems such as damage to the drive mechanism of flexible joint robots, damage to the stability of the control system, and jumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] This embodiment provides a mode-based intelligent control method for a position-limited flexible joint robot. The overall process is as follows figure 1 As shown, the method is described in detail by taking a double-link flexible joint robot as an example, and its detailed implementation process includes:

[0094] Step 1. Establish the dynamic model of the double-link flexible joint robot:

[0095]

[0096]

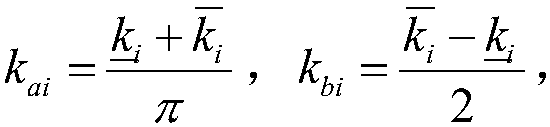

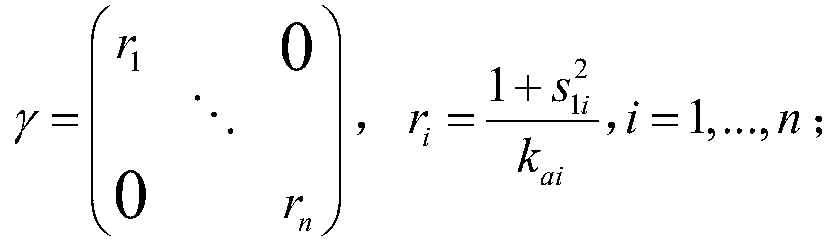

[0097] where q 1 =[q 11 ,q 12 ] represents the rotation angle vector of the connecting rod, q 2 =[q 21 ,q 22 ] represents the rotation angle vector of the motor, M(q 1 )∈R 2×2 Indicates the inertia matrix of the connecting rod, J∈R 2×2 is the motor inertia matrix that is diagonally positive definite, in addition, is the Coriolis force and centrifugal force matrix, g(q 1 ) represents the gravity term. K∈R 2×2 is the stiffness matrix of the flexible joint, and is also a constant matrix that is diagonally positive definite, so K -1 is also a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com