Deep blind hole cleaning device for mechanical production and maintenance

A technology of cleaning device and deep blind hole, applied in the field of mechanical equipment, can solve the problems of poor uniformity of cleanliness, splashing of pollutants, troublesome operation, etc., and achieve the effects of simple structure, high cleaning efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

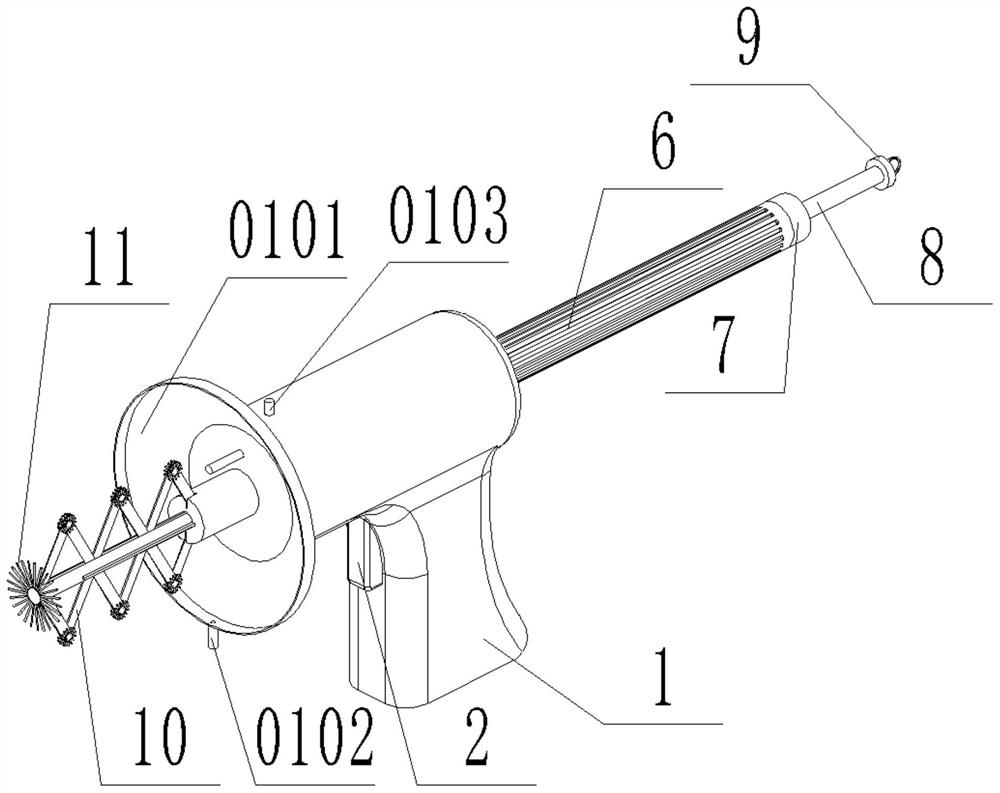

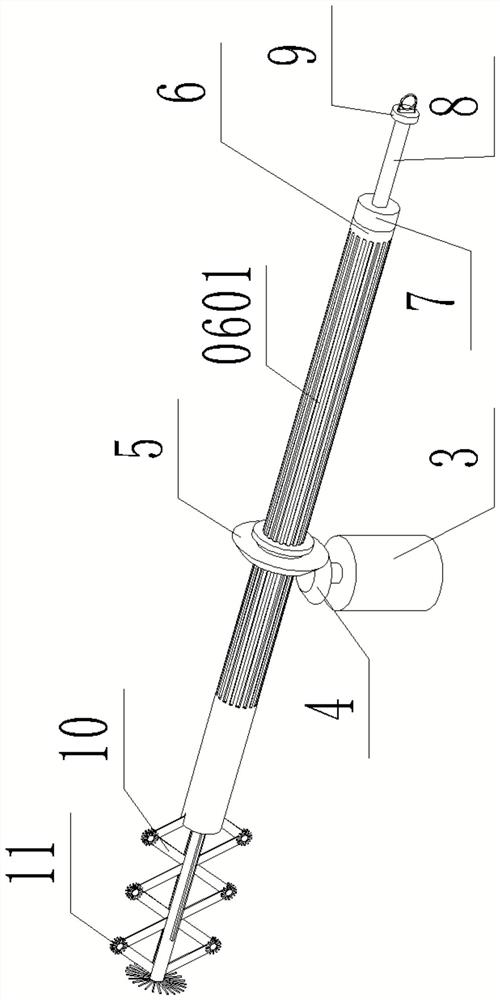

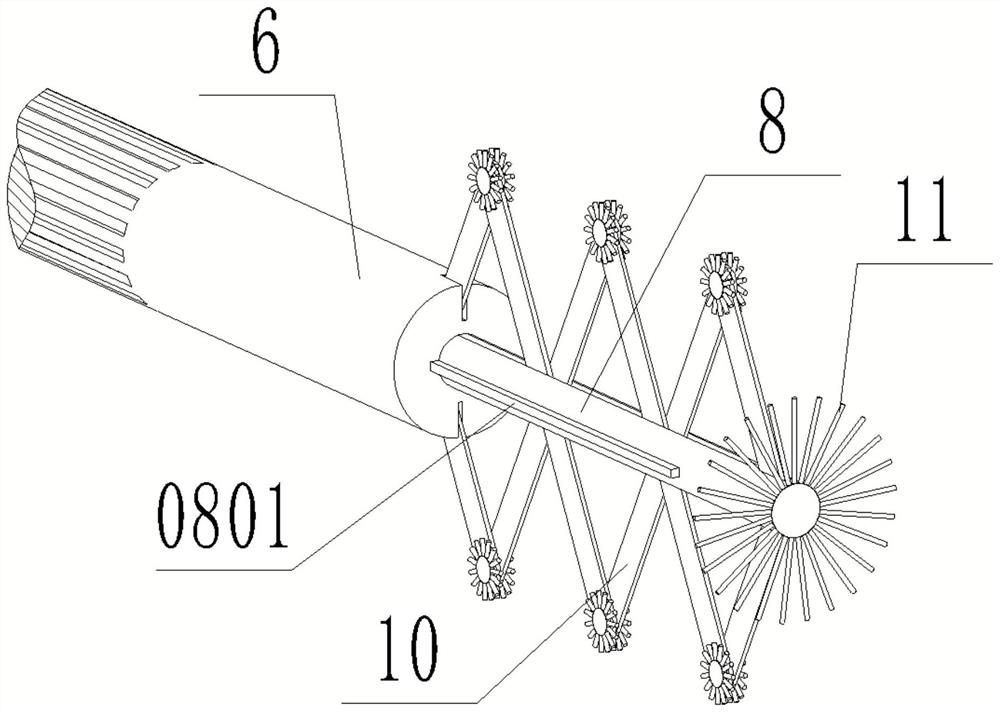

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a deep blind hole cleaning device for mechanical production and maintenance, including: a gun body 1, a cleaning agent collection cover 0101, a cleaning agent return pipe 0102, a cleaning liquid adding pipe 0103, a manual button 2, a motor 3, and a driving bevel gear 4. Driven bevel gear 5, diameter adjusting rod 6, spline teeth 0601, diameter adjusting wheel 7, pulling rod 8, sliding key 0801, T-shaped chute 0802, hand shaft 9, connecting rod 10, cleaning brush 11 and the hinge shaft 12; the handle part of the gun body 1 is fixedly connected with a group of motors 3; the rotating shaft of the motor 3 is fixedly connected with a group of driving bevel gears 4; the inner side of the top of the gun body 1 is axially connected with a group of driven bevel gears 5. The inner hole of the driven bevel gear 5 is coaxially slidably connected with a set of diameter adjusting rods 6; the right end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com