Emulsifying device for emulsion matrix experiment

An emulsification device and latex matrix technology, which is applied to mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve the problem of inability to accurately control the shear rate and emulsification temperature, and the inability to ensure the formation of latex matrix Milk stability and other issues, to achieve the effect of improving safety and stability, simple structure, and ensuring emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

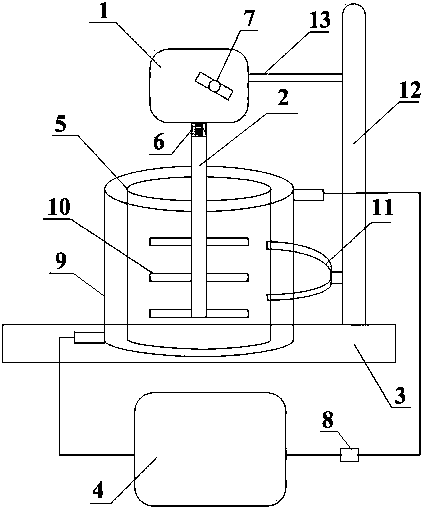

[0014] Such as figure 1 As shown, an emulsification device for latex matrix experiments includes a motor 1, a shear paddle 2, a base 3 and a beaker 5, the base 3 has the function of an operating platform, and the beaker 5 is arranged in a container 9 for heating, as shown in the figure Container 9 is cylindrical, and certainly container 9 can also be other shapes, and container 9 is equipped with hot water, and container 9 is arranged on the base 3, and container 9 is used for heating beaker 5 exactly, guarantees the latex matrix constant temperature in beaker 5.

[0015] A support rod 12 is arranged on one side of the base 3, and a connecting rod 13 is installed horizontally on the upper end of the supporting rod 12. The motor 1 is installed on the connecting rod 13, the output shaft of the motor 1 is vertically downward, and the output shaft thread of the motor 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com