Strip sticking device for training shoe production

A technology of sticking strips and cylinders, which is applied in the field of training shoes production, can solve the problems of low production efficiency of training shoes, and achieve the effect of improving production efficiency and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

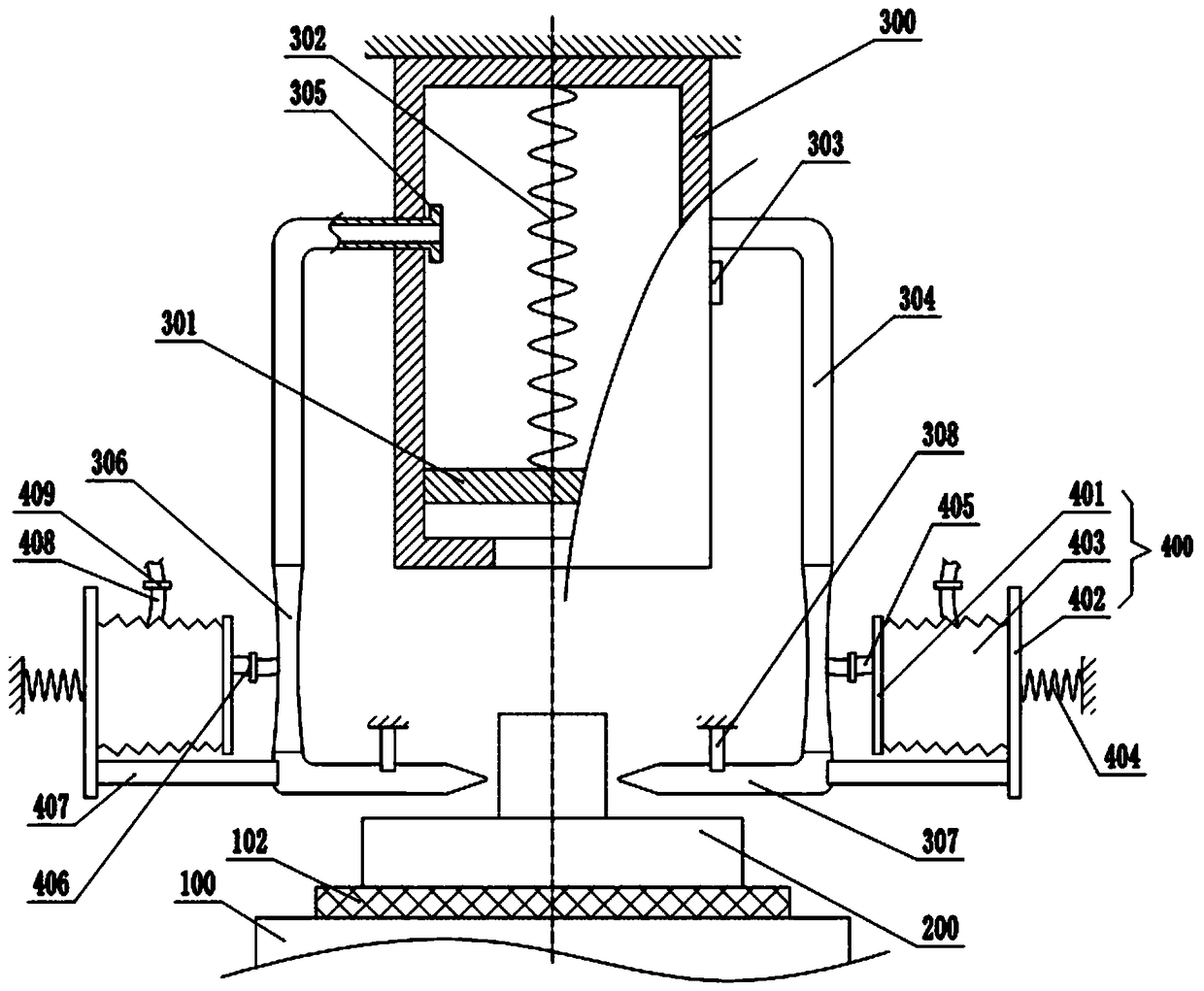

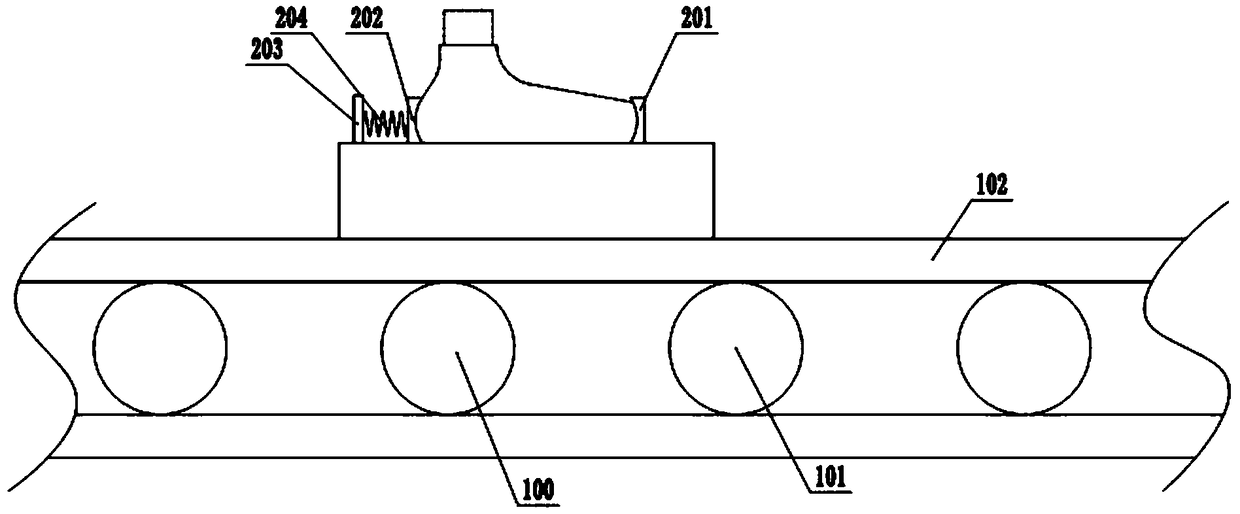

[0026] The reference signs in the accompanying drawings of the description include: driving roller 100, supporting roller 101, conveyor belt 102, positioning seat 200, positioning block 201, supporting block 202, mounting plate 203, supporting spring 204, cylinder body 300, slider 301, the second A spring 302, an air intake check valve 303, an air outlet pipe 304, a boss 305, a necking section 306, a nozzle pipe 307, a support frame 308, a glue supply device 400, a positioning plate 401, a push plate 402, an air bag 403, the second Spring 404 , glue outlet pipe 405 , first glue inlet check valve 406 , horizontal bar 407 , glue inlet pipe 408 , second glue inlet check valve 409 .

[0027] The embodiment is basically as attached figure 1 Shown:

[0028] The sticking device for the production of training shoes includes a frame on which a transmission unit and a gluing unit are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com