An apparatus for producing microspheres of customizable sizes efficiently

A technology of microspheres and drainage devices, which is applied in the direction of making medicines into special physical or taking form devices, heat insulation devices, manufacturing tools, etc., can solve the problems of difficulty in meeting large-scale production industrial needs and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] It should be understood that the following examples belong to a part of our ongoing research on similar devices of the present invention, are for the convenience of readers to better understand this invention, and are only used to illustrate the present invention and not limit the scope of the present invention.

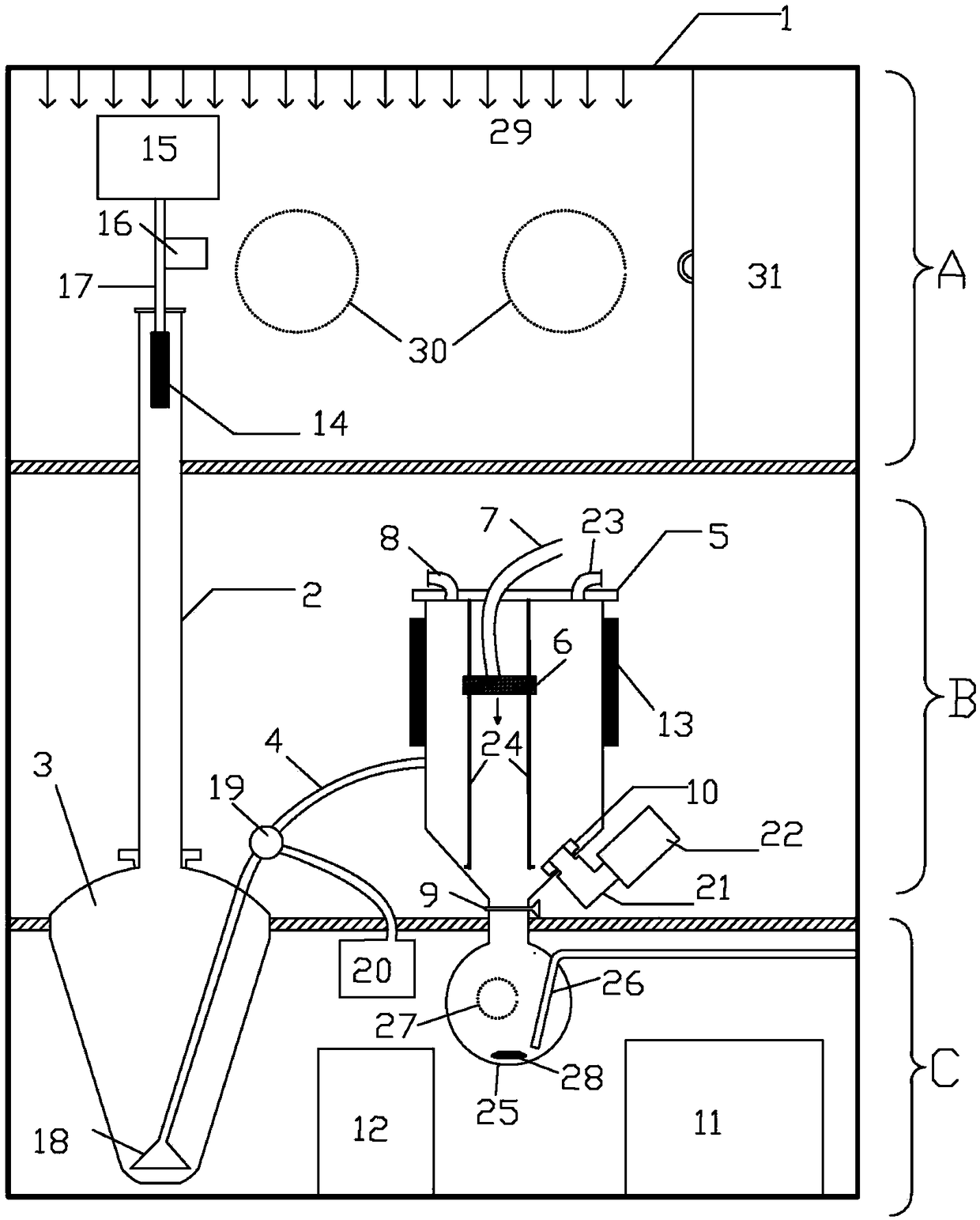

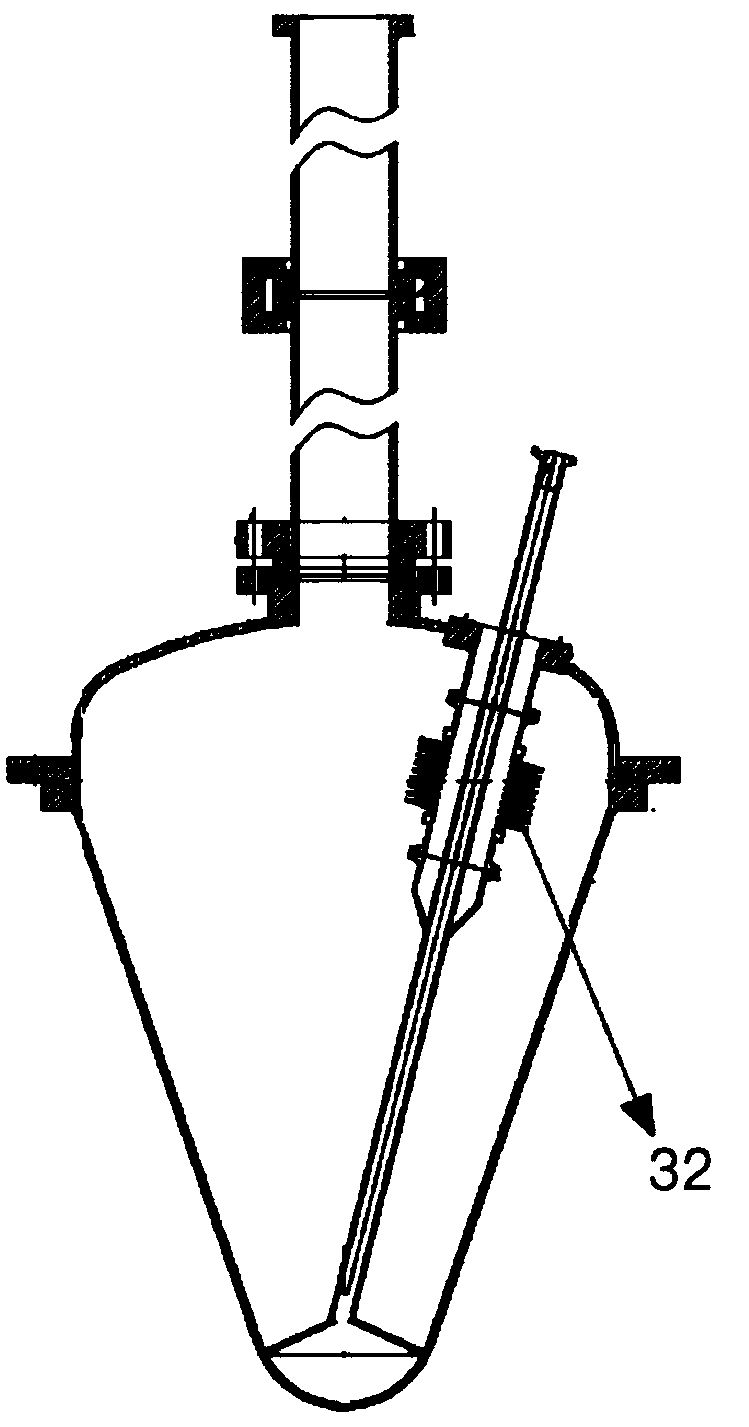

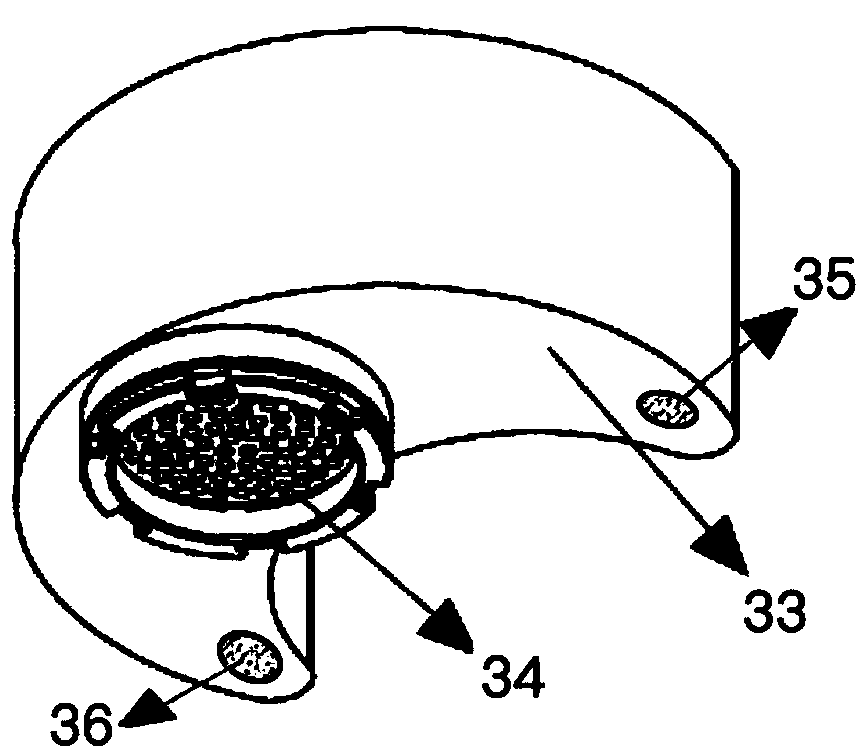

[0070] Such as figure 1 As shown, the device for preparing microspheres includes an SPG membrane 14, and the solution containing microsphere-forming materials can be extruded through the SPG membrane to form microsphere droplets under the pressure of high-pressure gas; microsphere solidification column 2, microsphere droplets Settled to the bottom in the microsphere solidification column and solidified and formed by solvent extraction; microsphere collector 3, used to collect the microspheres solidified and formed; post-processing device 5, used to carry out organic solvent and organic solvent for the solidified formed microspheres Removal of other impurities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com