A laser current drive circuit and drive method with maximum current protection

A technology of current drive and maximum current, which is applied to emergency protection circuit devices, emergency protection circuit devices, lasers, etc. for limiting overcurrent/overvoltage, and can solve problems such as response lag and insufficient current setting accuracy to improve safety. Unique, easy to implement, and high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

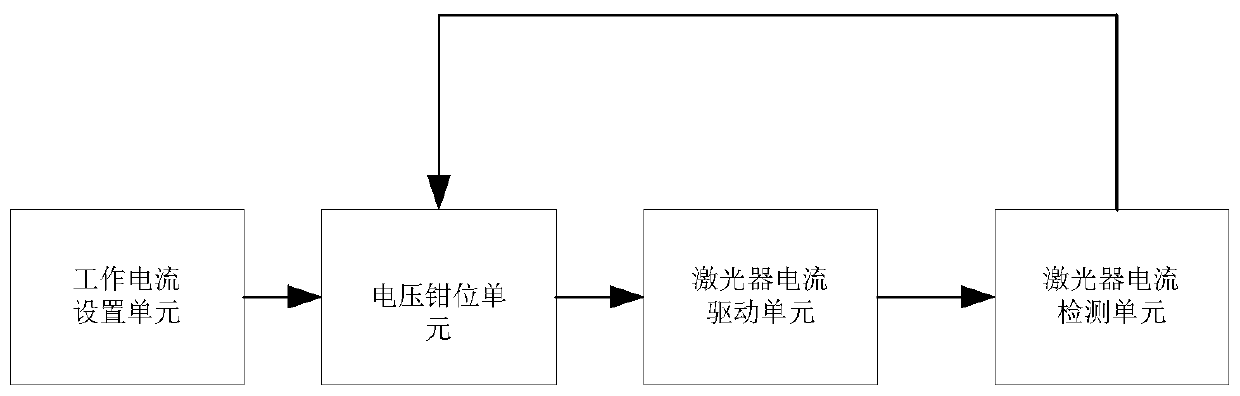

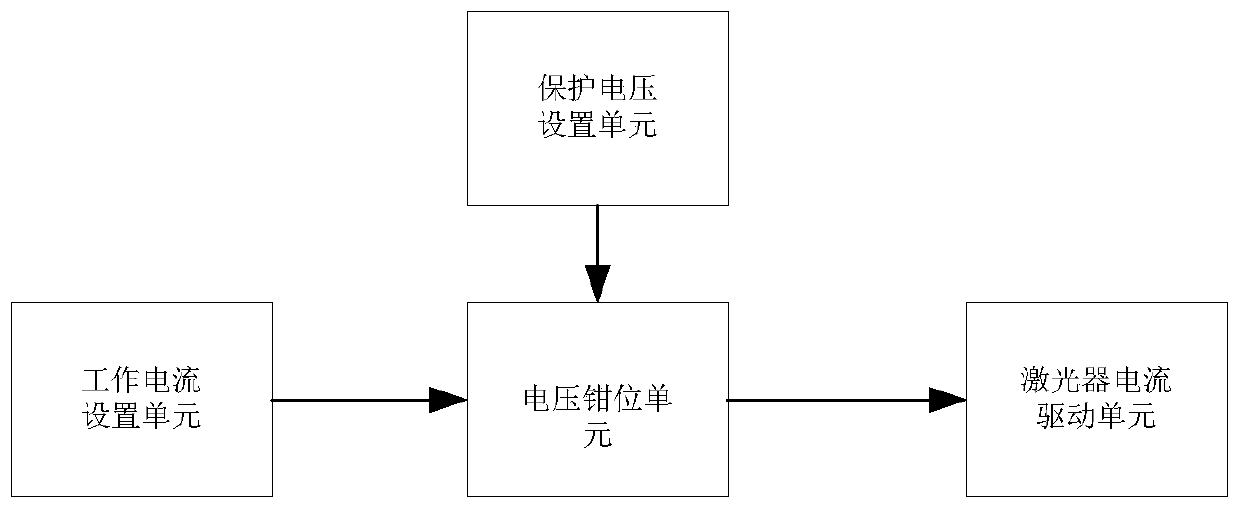

[0053] Embodiment 1 of the present invention provides a laser current drive circuit with maximum current protection, such as image 3 As shown, it includes a working current setting unit, a voltage clamping unit, a protection voltage setting unit and a laser current driving unit, wherein the working current setting unit, the protection voltage setting unit and the laser current driving unit are respectively connected to the voltage clamping unit, specific:

[0054] The protection voltage setting unit is used to set the reference protection voltage for the voltage clamping unit as a basis for comparison; wherein, the reference protection voltage value is calculated according to the maximum current allowed by the laser;

[0055] The voltage clamping unit is used to obtain the reference protection voltage of the protection voltage setting unit, and by comparing the input quantity of the working current setting unit, determine that the output to the laser current driving unit is t...

Embodiment 2

[0069] After the present invention provides the laser current drive circuit with maximum current protection described in Embodiment 1, the present invention also provides a laser current drive method with maximum current protection. The principle of laser current drive circuit with maximum current protection, specifically:

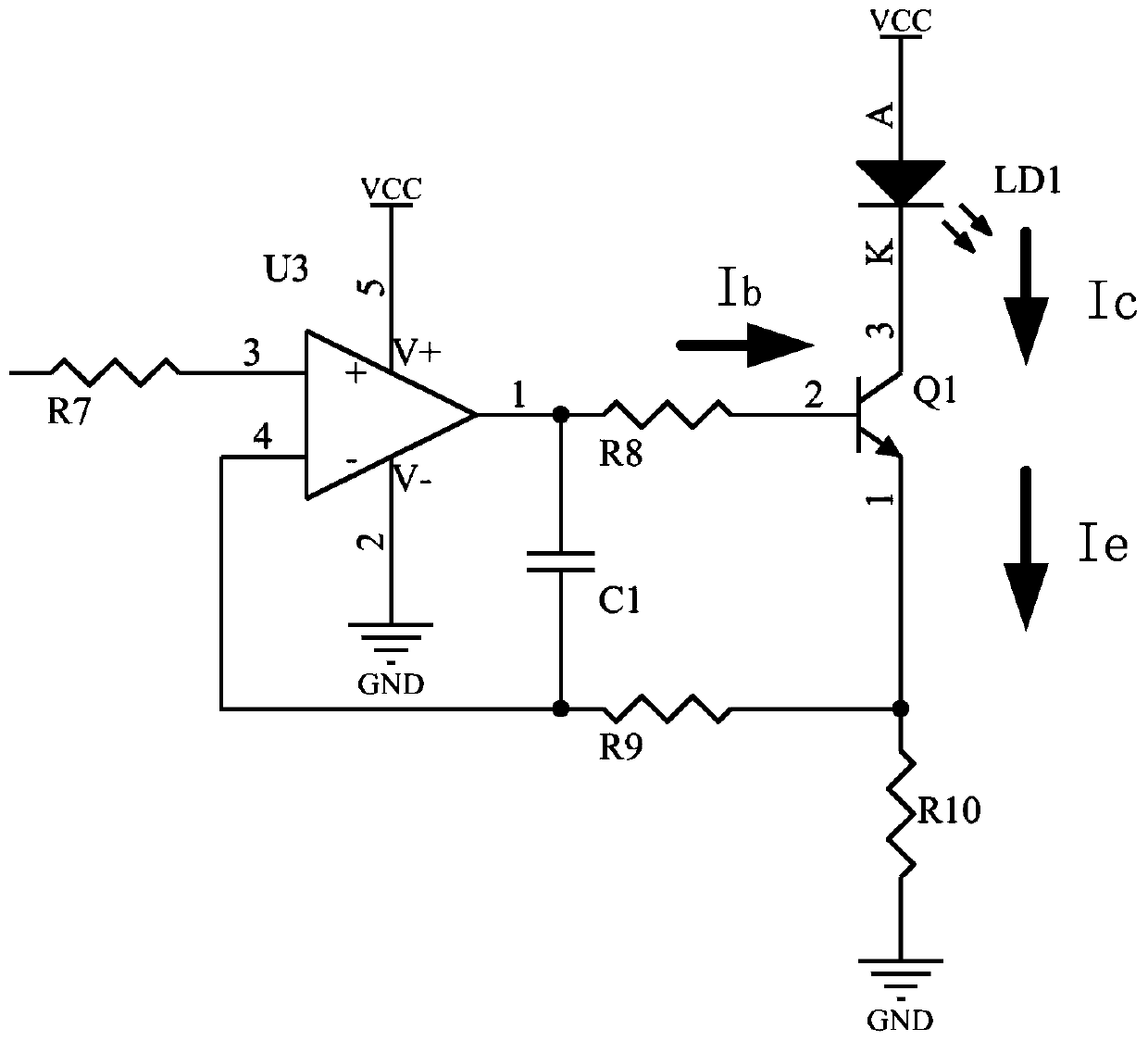

[0070] When the output voltage Vin At this time, the voltage clamping unit is in a normal working state, and the output Vin of the laser LD1 driving current I and the current setting unit are in accordance with the proportional coefficient Corresponding change; wherein, Vmax is the output of the protection voltage setting unit and the reference protection voltage of the voltage clamping unit; the resistor R8 is a resistor connected between the collector of the transistor Q1 and the positive input port of the operational amplifier U3;

[0071] When the output voltage Vin of the working current setting unit is > 2Vmax, the output voltage Vo1 of the operatio...

Embodiment 3

[0087] Based on the laser current drive circuit with maximum current protection described in Embodiment 1, the embodiment of the present invention further elaborates the optimal setting of supporting parameters and the corresponding implementation process in a specific application scenario.

[0088] Include the complete drive circuit diagram of the improvement point of the present invention, as Image 6 As shown, the current I1 is the current flowing through the resistor R8, the current I2 is the current flowing through the resistor R10, and the current I is the current flowing through the laser LD1 and the sampling resistor RS. Between the output terminal of the integrating capacitor C1 and the inverting input terminal, the value of C1 is 100pF, and the value of R1 is 1K. The function of C1 can limit the bandwidth of the current drive unit to around 1MHz, and at the same time, it is used to force the op amp between the non-inverting terminal and the inverting terminal The vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com