Clamping-tooth-type refractory material mounting clamp and using method thereof

A technology of mounting clamps and clamping teeth, which is applied in the field of clamping clamps for refractory materials, can solve problems affecting the quality and progress of the installation of industrial furnace linings, unsatisfactory installation effects, friction fatigue, etc., to solve the problem of repetitive labor and Installation quality, improvement of labor efficiency, effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

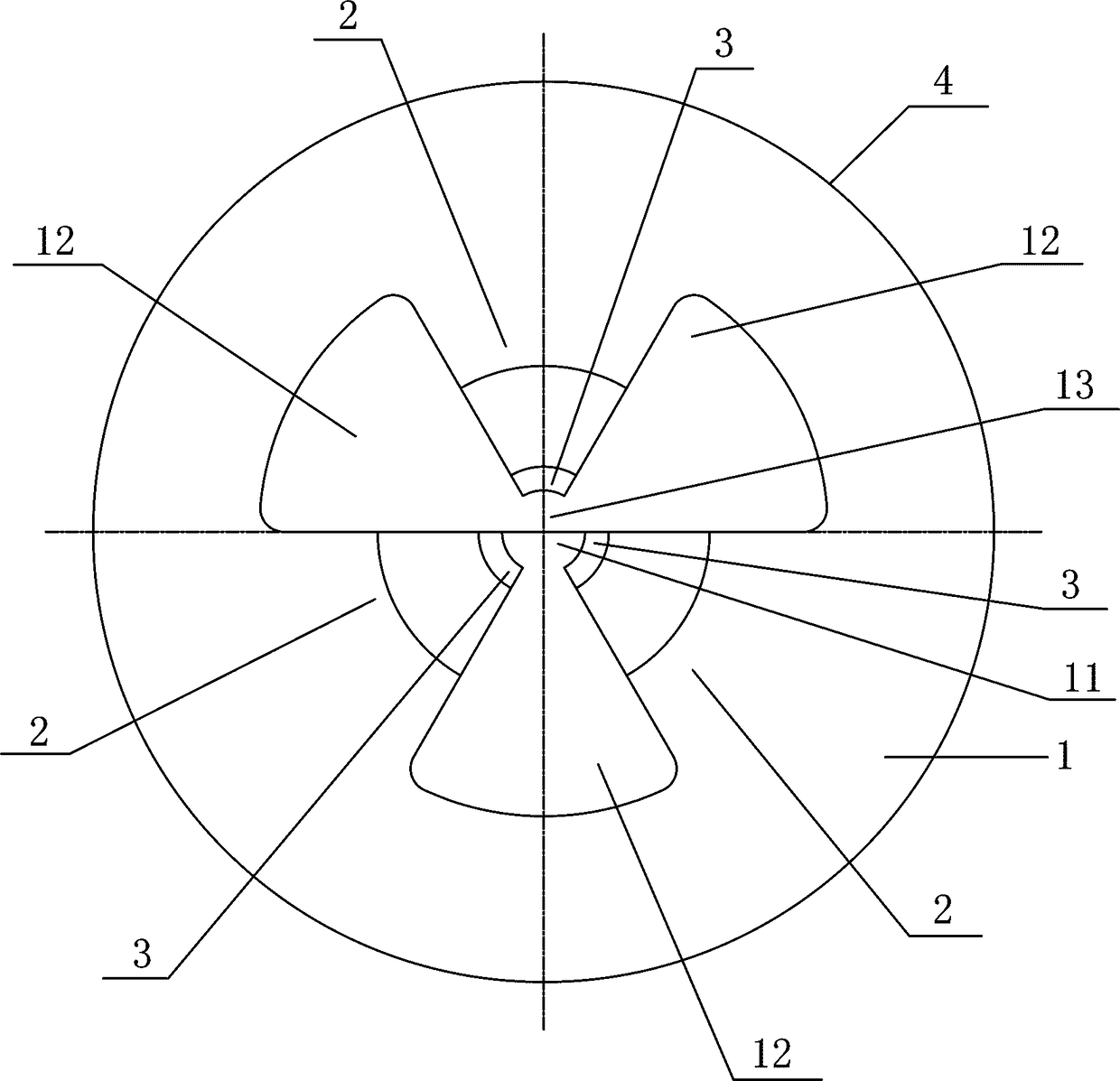

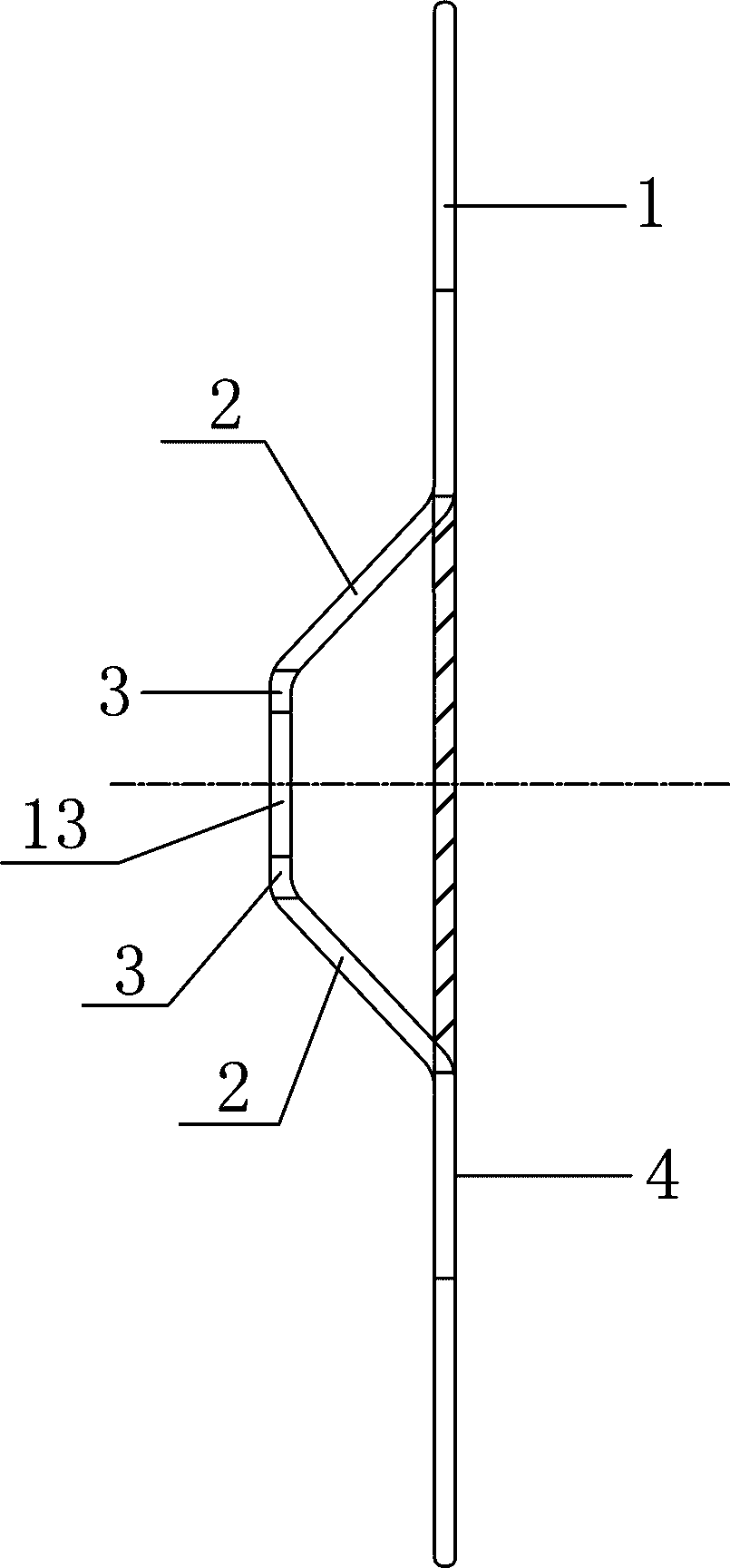

[0032] A locking type refractory mounting clip, including a circular bottom plate 1, a support plate 2 and locking teeth 3, such as figure 1 and figure 2 As shown, the specific structure is:

[0033] The center of the base plate 1 is provided with a circular hole 11 concentric with the base plate 1. At least three fan-shaped blocks are punched out on the base plate 1 to form at least three fan-shaped holes 12. The centers of the fan-shaped holes 12 coincide with the centers of the base plate 1. Evenly distributed around the bottom plate 1; the triangular block between two adjacent fan-shaped holes 12 becomes the support plate 2, and each support plate 2 is inclined in the same direction, so that the envelope of the outer surface of each support plate 2 forms a circular truncated shape, The inner end of the support plate 2 is provided with locking teeth 3 , and the inner end of each locking tooth 3 is enveloped to form a small circular hole 13 concentric with the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com