Bearing installing device

A technology for installing devices and bearings, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve problems such as easy rotation, reduced service life of bearings, and bearing abrasions, so as to avoid abrasions and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

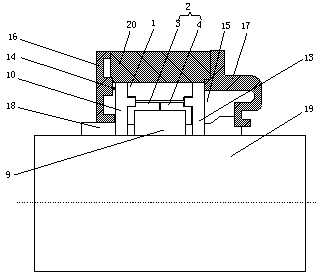

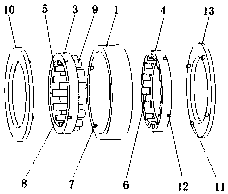

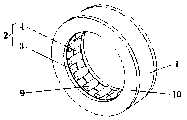

[0019] Embodiment 1: A bearing installation device, including a bearing, a bearing 15, an elastic member 14 for preloading, a bearing outer cover 16 and a bearing inner cover 17 forming a bearing chamber 15, the bearing is installed in the bearing chamber 15 , the bearing outer cover 16 and the bearing inner cover 17 are provided with a fixing part 20, the bearing is fixedly connected with the fixing part 20, the bearing includes a first ring body 1 and a second ring body 2, the The first ring body 1 is arranged on the inner ring side of the second ring body 2, and one end side of the first ring body 1 is provided with an A ring-shaped sealing cover 10, and the other end side is provided with a B ring-shaped sealing cover 13. The A ring-shaped sealing cover 10 is axially positioned on the rotating shaft 19 through the oil seal 18, the B ring-shaped sealing cover 13 is axially positioned on the rotating shaft 19 through the retaining ring 8, and the bearing outer cover 16 and th...

Embodiment 2

[0020] Embodiment 2: A bearing installation device includes a bearing, a bearing 15, an elastic member 14 for preloading, a bearing outer cover 16 and a bearing inner cover 17 forming a bearing chamber 15, and the bearing is installed in the bearing chamber 15 , the bearing outer cover 16 and the bearing inner cover 17 are provided with a fixing part 20, the bearing is fixedly connected with the fixing part 20, the bearing includes a first ring body 1 and a second ring body 2, the The first ring body 1 is arranged on the inner ring side of the second ring body 2, and one end side of the first ring body 1 is provided with an A ring-shaped sealing cover 10, and the other end side is provided with a B ring-shaped sealing cover 13. The A ring-shaped sealing cover 10 is axially positioned on the rotating shaft 19 through the oil seal 18, the B ring-shaped sealing cover 13 is axially positioned on the rotating shaft 19 through the retaining ring 8, and the bearing outer cover 16 and ...

Embodiment 3

[0021] Embodiment 3: A bearing installation device includes a bearing, a bearing 15, an elastic member 14 for preloading, a bearing outer cover 16 and a bearing inner cover 17 forming a bearing chamber 15, and the bearing is installed in the bearing chamber 15 , the bearing outer cover 16 and the bearing inner cover 17 are provided with a fixing part 20, the bearing is fixedly connected with the fixing part 20, the bearing includes a first ring body 1 and a second ring body 2, the The first ring body 1 is arranged on the inner ring side of the second ring body 2, and one end side of the first ring body 1 is provided with an A ring-shaped sealing cover 10, and the other end side is provided with a B ring-shaped sealing cover 13. The A ring-shaped sealing cover 10 is axially positioned on the rotating shaft 19 through the oil seal 18, the B ring-shaped sealing cover 13 is axially positioned on the rotating shaft 19 through the retaining ring 8, and the bearing outer cover 16 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com