Method and device for reinforcing damaged RC column rapidly via prefabricated part

A component and fast technology, applied in the field of rapid reinforcement, can solve problems such as easy force stripping reinforcement effect, difficult control of construction quality, long construction period, etc., achieve good reinforcement effect, ensure reinforcement construction quality, and reduce the effect of formwork engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

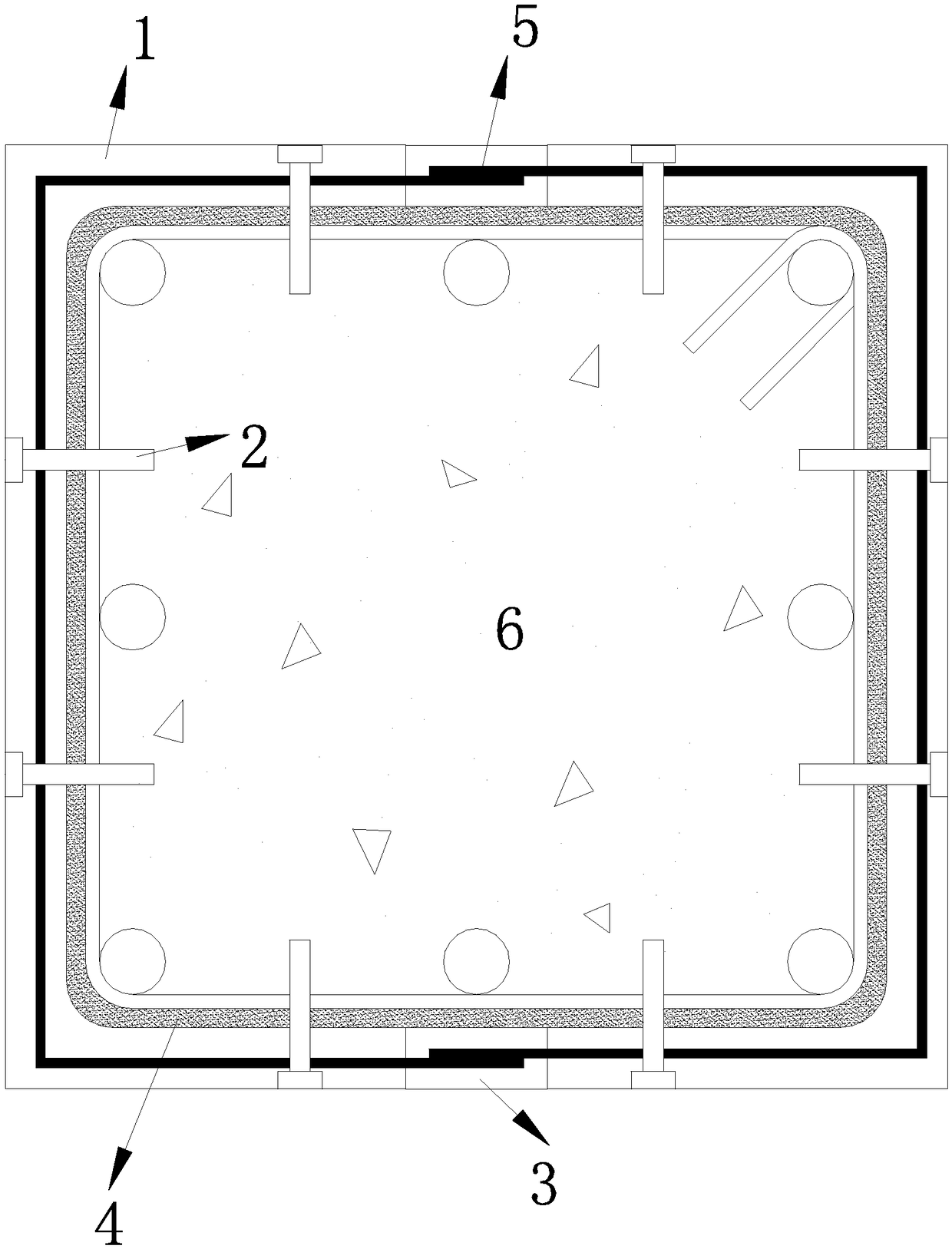

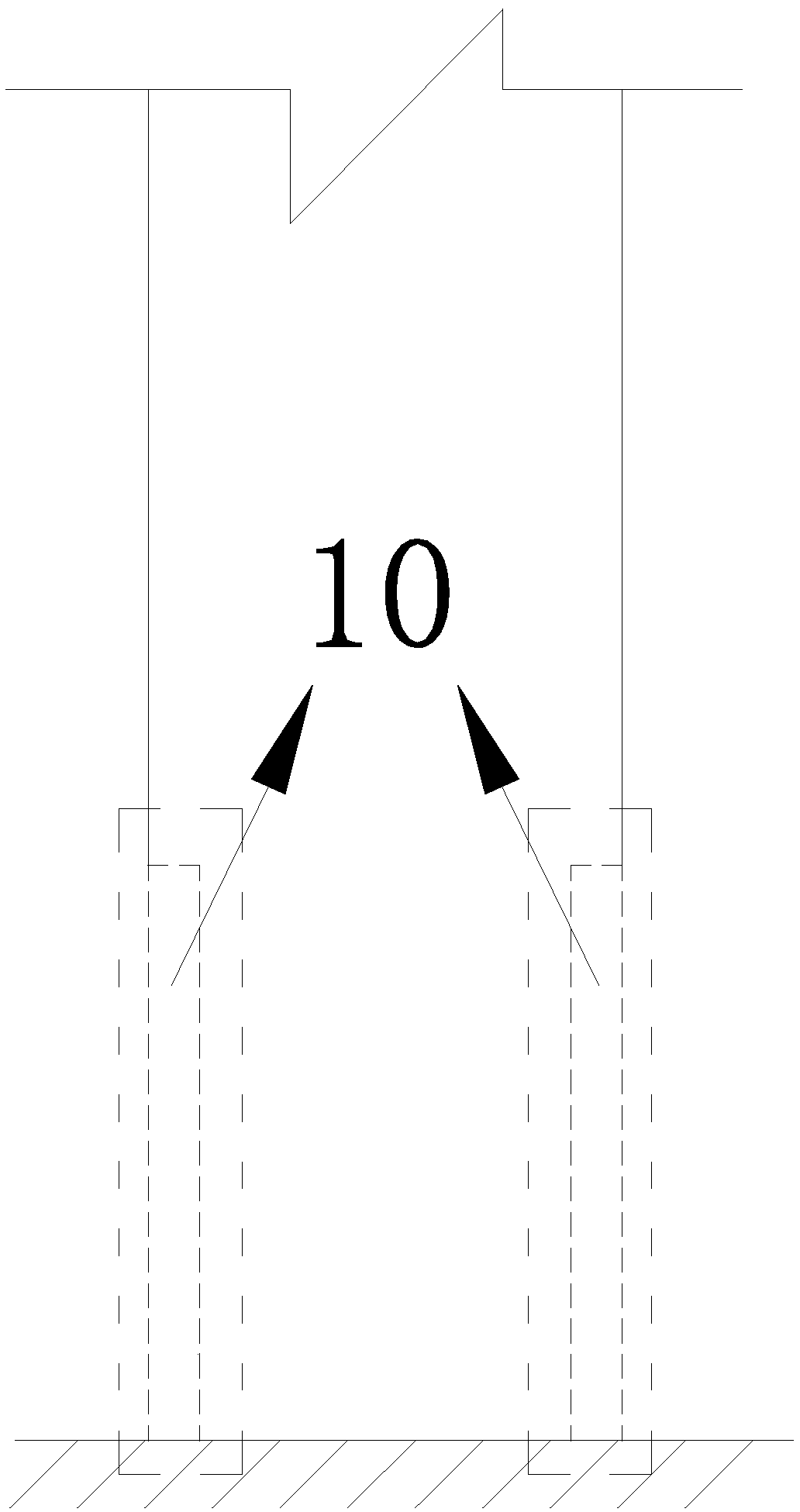

[0028] The present invention proposes a method and device for rapid reinforcement of damaged columns. The reinforcement device used in this method—the prefabricated parts can be prefabricated in advance in the factory, and the prefabricated parts only need to be spliced and then anchored to the column during on-site construction. As a whole, the damaged column can be quickly reinforced, and the seismic performance of the reinforced column can be effectively repaired. The specific implementation steps are as follows:

[0029] 1) The prefabricated construction steps of the trough-shaped prefabricated parts will be introduced in detail below;

[0030] 2) Make a groove mold, and the mold size selects the column size commonly used in engineering;

[0031] 3) The mold is accurately laid flat, and three positioning bars are arranged along the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com