Section bar module for wall surface mounting

A component and profile technology, which is applied in the field of profile components installed on the wall, can solve the problems of hollow drum falling off, large consumption of cement mortar, low temperature, etc., and achieve the effect of meeting the installation accuracy requirements, improving construction quality, and improving earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

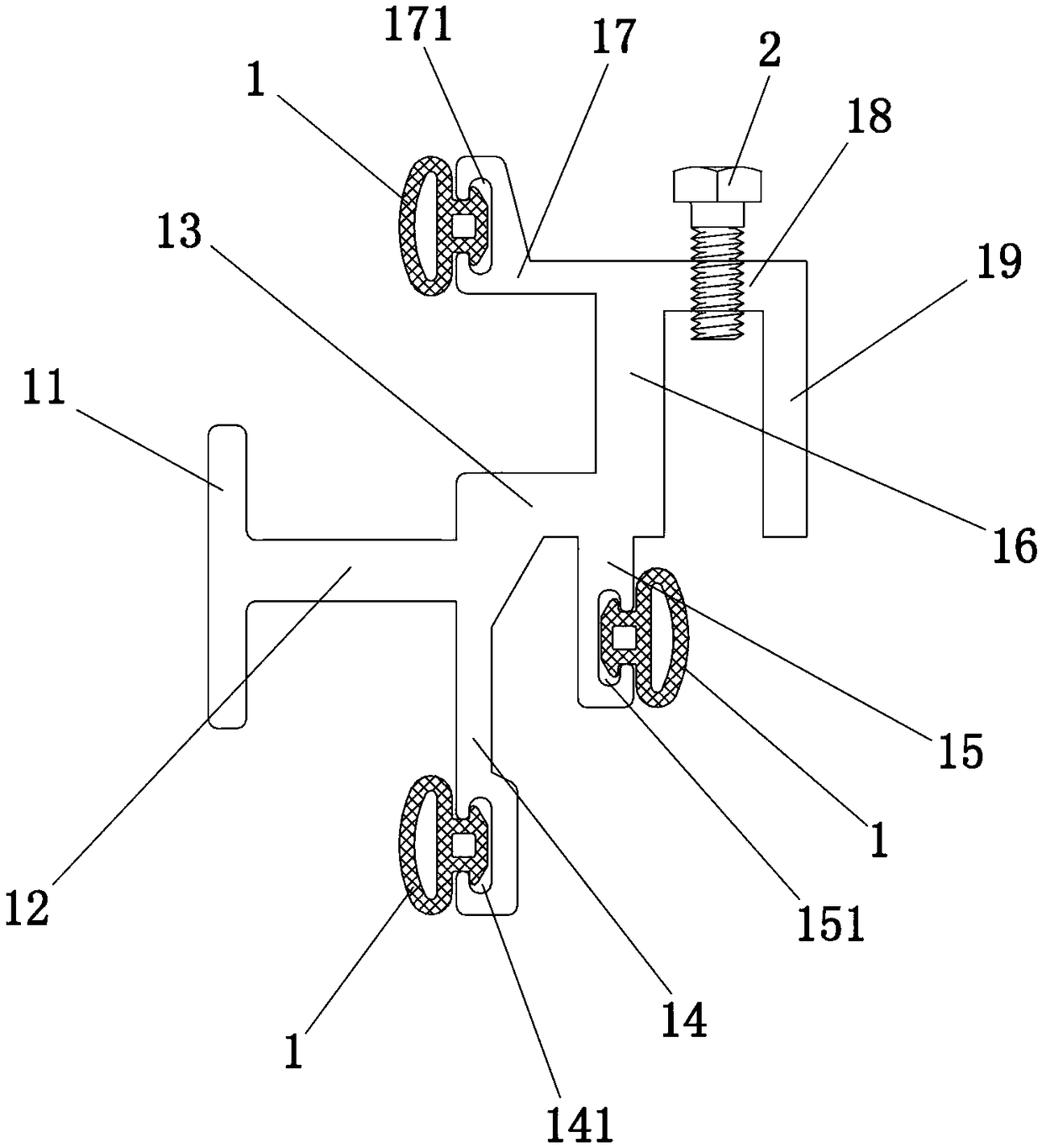

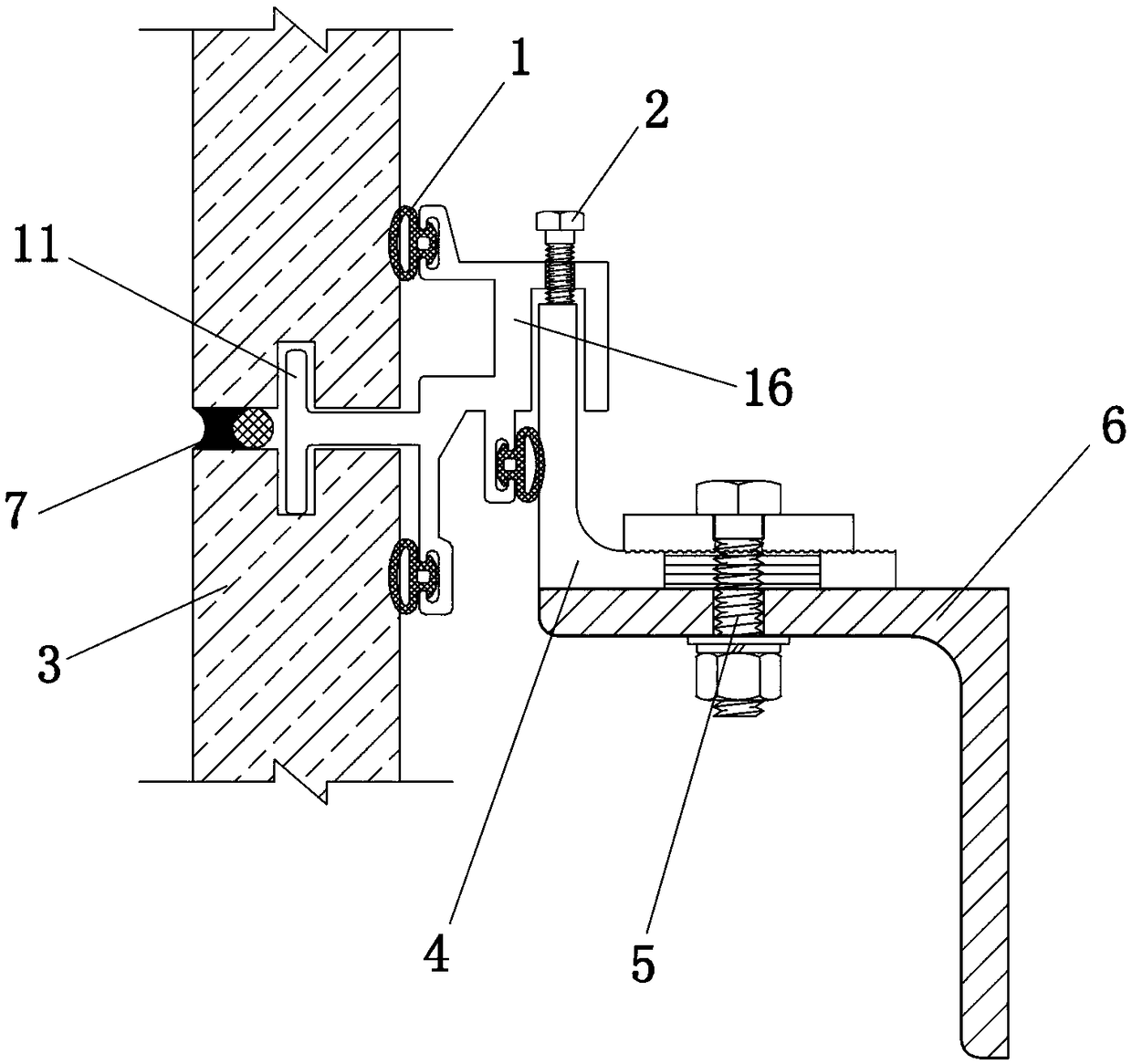

[0015] A profile component for wall mounting such as figure 1 , figure 2 As shown, the pendant body 11 is included, and the middle part of the right side of the pendant body 11 extends horizontally to the right to form a first transition body 12. An inverted T-shape is formed between the pendant body 11 and the first transition body 12, and is connected with the outer wall panel 3. The groove is matched to realize the fixing of the outer wall panel 3; the right end of the first transition body 12 is connected with a lower limit body 13; the lower limit body 13 extends vertically downward to form a left lower limit body 14 and a right lower limit body 15, and the lower left The limiting body 14 and the lower right limiting body 15 are used to limit the horizontal movement of the exterior wall panel 3 and the adjusting angle aluminum 4 provided on the keel 6; the right end of the lower limiting body 13 extends vertically upward to form a second transition body 16; The end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com