Textile slitting machine based on industrial camera positioning

An industrial camera and slitting machine technology, which is applied in the cutting of textiles, papermaking, and textile materials, can solve the problems of not being able to accurately identify the position of the cutting seam, and achieve the effects of stable cutting quality, easy operation, and good recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

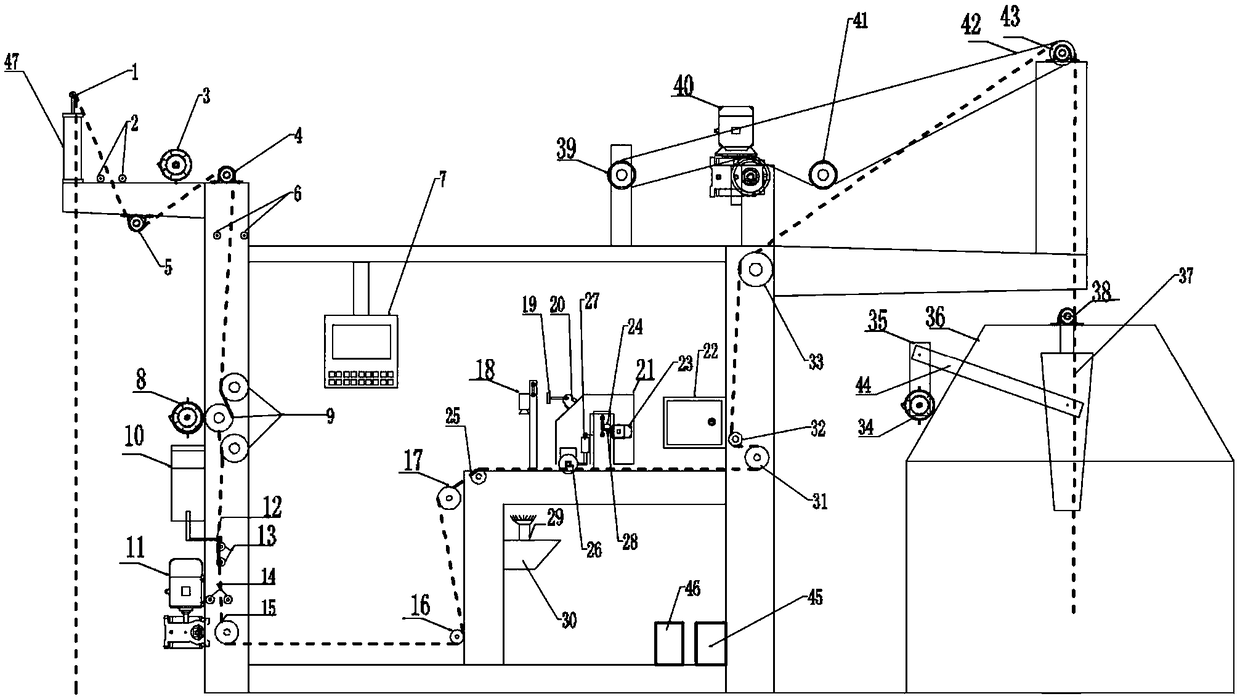

[0030] see figure 1 , the dotted line in the figure indicates the running track of the cloth. A textile slitting machine positioned by an industrial camera, which is sequentially equipped with a rough centering mechanism, a fine deviation correction mechanism, a flattening mechanism, a further deviation correction mechanism, a cloth feeding mechanism, a detection mechanism, a cutting mechanism and a cloth output mechanism from front to back; The coarse centering mechanism includes a first solenoid valve, a first cylinder 47, a centering rod 1 and a first centering light pipe 2, the first centering light pipe 2 is connected with the first solenoid valve, and the first solenoid The valve controls the first cylinder 47 to drive the centering rod 1 to move up and down. After the cloth enters the slitting machine equipment, the left and right deviation signal of the cloth is detected by the first centering optical tube 2, and the left and right deviation signal of the cloth is out...

Embodiment 2

[0040] In the above mentioned textile slitting machine positioned by the industrial camera, the main body frame of the slitting machine is also provided with a man-machine interface 7, and the man-machine interface 7 is connected to an industrial computer. The human-computer interaction interface 7 can display the real-time operating conditions of the equipment, and is also used to change the parameter settings, control the operation of the equipment through the industrial computer, or perform the start-stop operation of the equipment.

Embodiment 3

[0042] The slitting machine is also provided with a left and right mechanism, and the left and right mechanism is provided with a left and right motor 34 controlled by a frequency converter. The rocker arm 35 is connected, and the swing arm 35 is connected with the swing bucket 37 through the connecting rod 44, and the swing is completed through the swing bucket 37; the swing mechanism is also provided with a bracket 36, and the swing motor 34 is fixed on the bracket 36. The bucket 37 is fixed inside the bracket 36 through the left and right bucket bearings 38 . After cutting, the cloth is exported by the cloth outlet mechanism and then enters the swing mechanism. The swing motor 34 is controlled by a frequency converter. The frequency converter controls the swing frequency of the swing motor according to the frequency output by the PLC 46, thereby realizing the synchronization of the power system of the swing mechanism and the main machine of the slitting machine. , the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com