A reusable energy absorbing structure for collision preventing of rail vehicles

An energy-absorbing structure and rail vehicle technology, which is applied in the direction of railway vehicle wheel guards/buffers, railway car body parts, transportation and packaging, etc., can solve the problem that the absorbable energy level of the impact speed limit cannot meet the requirements of rail vehicles, etc. Achieve perfect mechanical characteristic curve, stable cushioning force and good energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

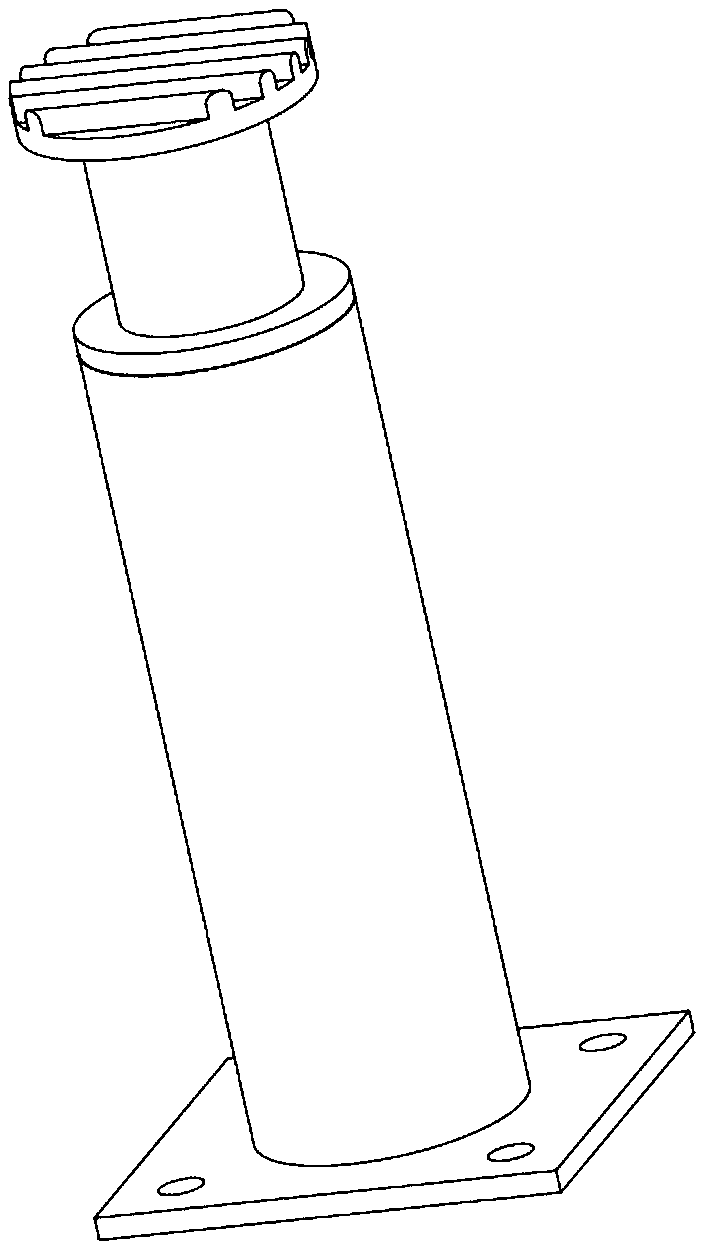

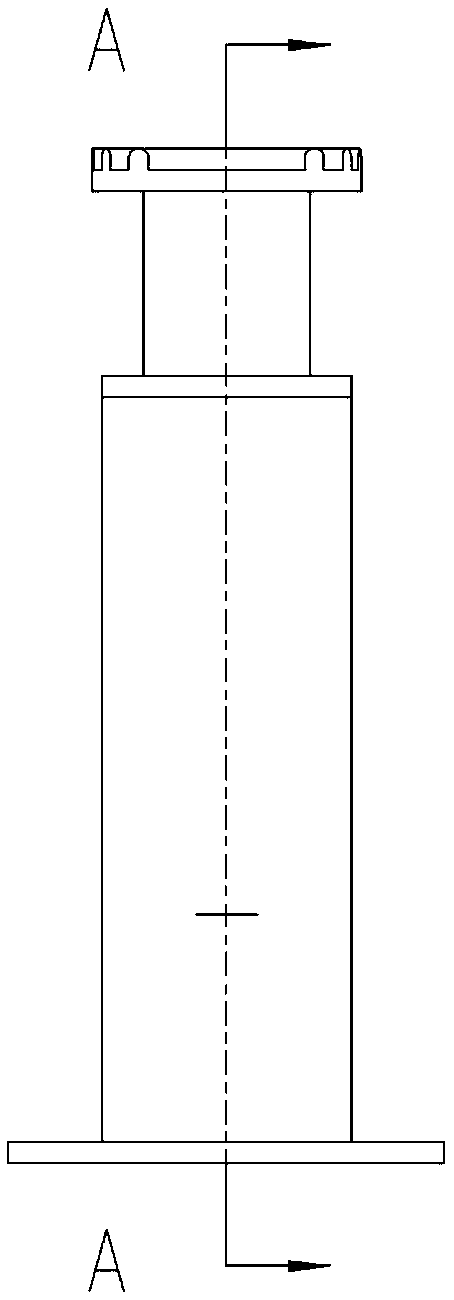

[0032] Such as Figure 1-7 As shown, the present invention provides a reusable rail vehicle anti-collision energy-absorbing structure, the energy-absorbing structure includes an impacted rod, an outer tube, a damping structure, a restoring structure and an end base; the damping structure includes a damping Plug, guide tube, damping elastic element and small base at the end, the recovery structure includes a recovery piston and a recovery elastic element; the outer tube is a tubular structure and the interior is divided into a front cavity and a rear cavity by a partition, the A through-hole-shaped damping hole is provided on the partition so that the damping fluid can circulate between the front cavity and the rear cavity; the impacted rod includes an impacted end at the front end and a piston end at the rear end, and the impacted rod The piston end is arranged inside the outer tube, and the impacted end is arranged outside the outer tube; when the damping plug is in the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com