Embroidery machine inkjet device, inkjet control method and system

A technology of control system and inkjet device, applied in embroidery machines, auxiliary devices, printing devices, etc., can solve the problems of reducing work efficiency, complicated operation, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

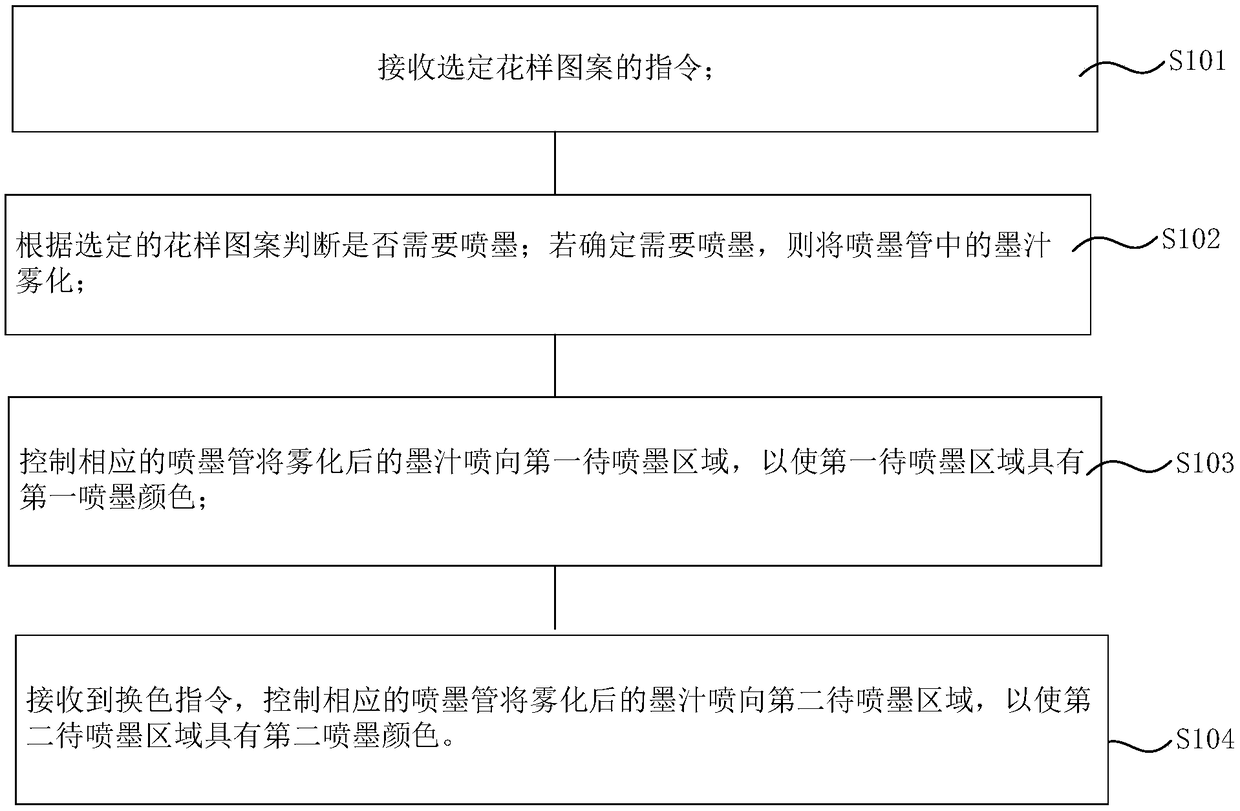

[0041] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

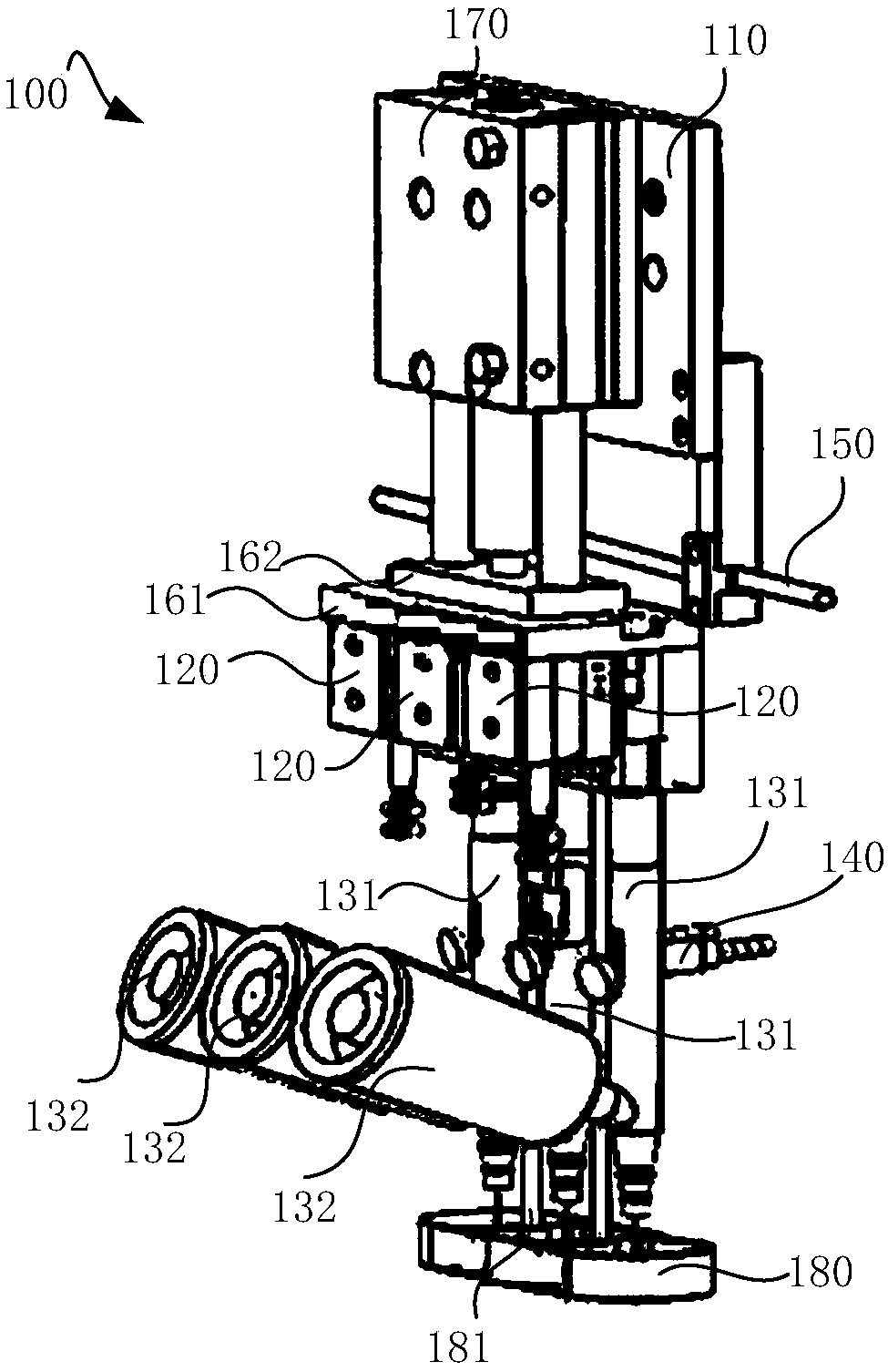

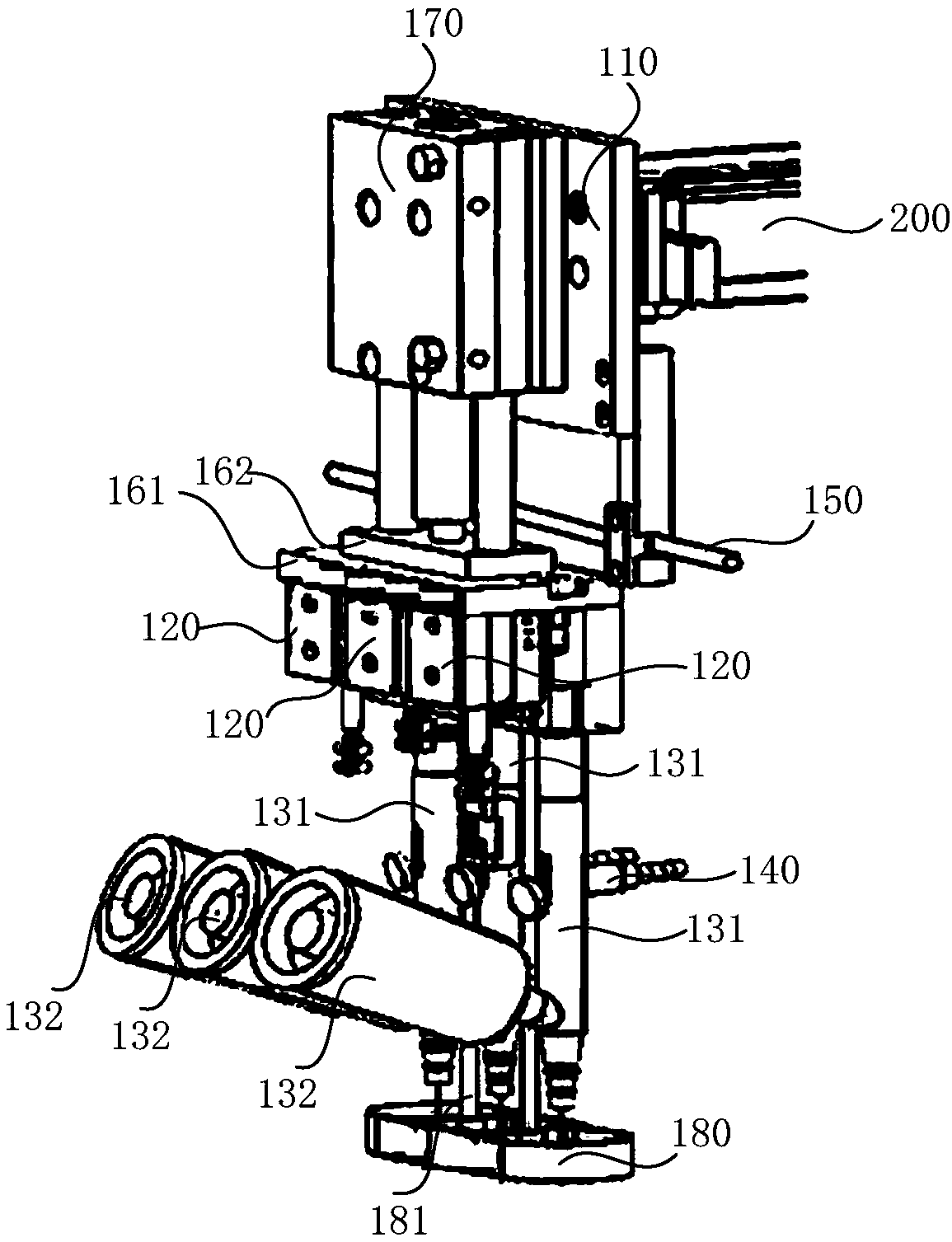

[0042] Refer below Figure 1-Figure 2 An inkjet device for an embroidery machine according to the embodiment of the first aspect of the present application is described.

[0043] Such as Figure 1-Figure 2As shown, the present application provides an embroidery machine inkjet device 100, including: a fixed seat 110, an air circuit switch 120 and an inkjet; there are multiple air circuit switches 120 and inkjet; the fixed seat 110 is used for embroidery machine connection; each inkjet device includes an inkjet tube 131 and an ink storage tube 132, the ink jet tube 131 is installed at the lower end of the fixed seat 110, and the ink storage tube 132 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com