Feeding mechanical arm and feeding method thereof

The technology of a robotic arm and a robotic arm, which is applied to the feeding robotic arm and its feeding field, can solve the problems of food waste, difficulty in control, and restriction, and achieve the effects of a wide range of applications, low cost and high success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

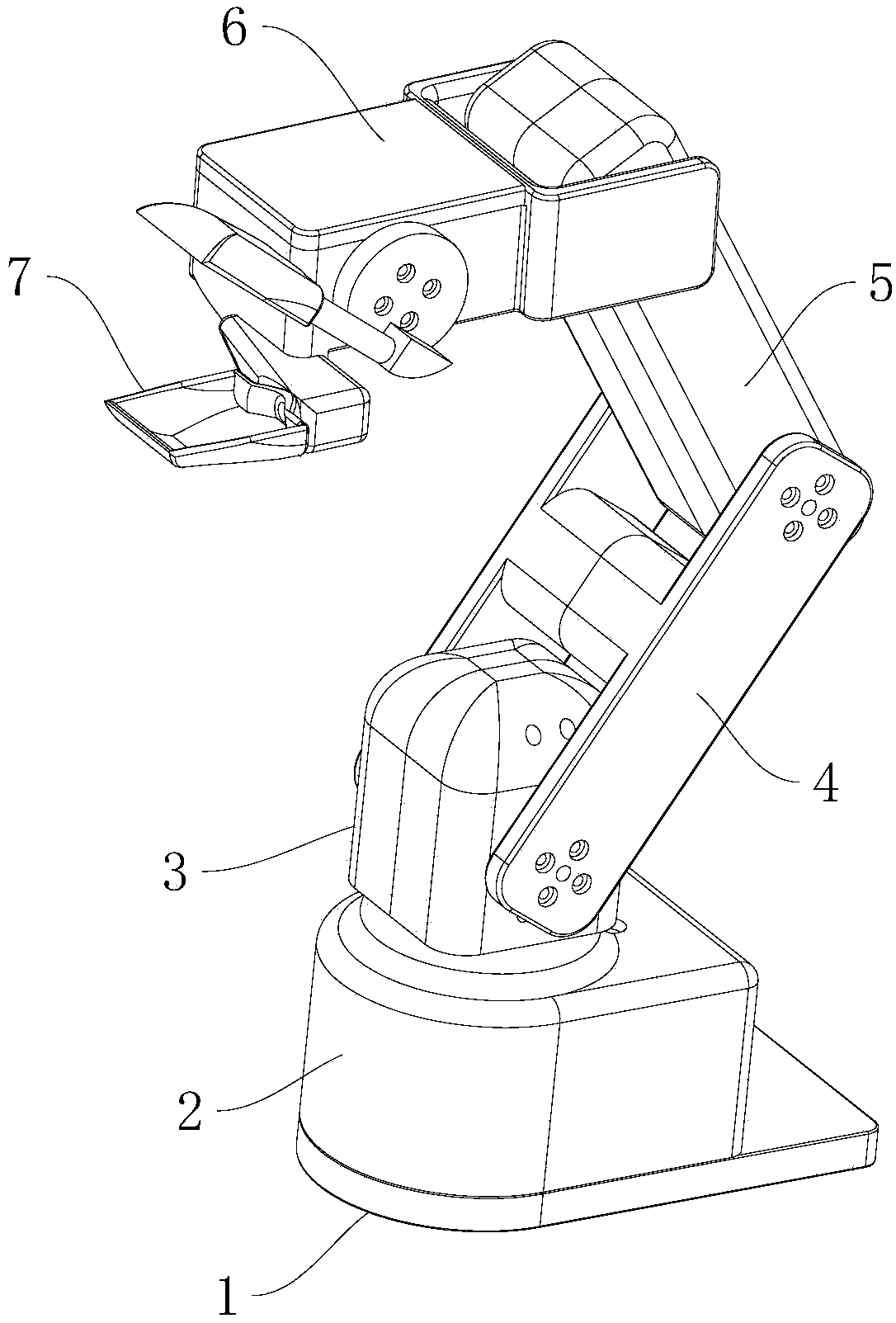

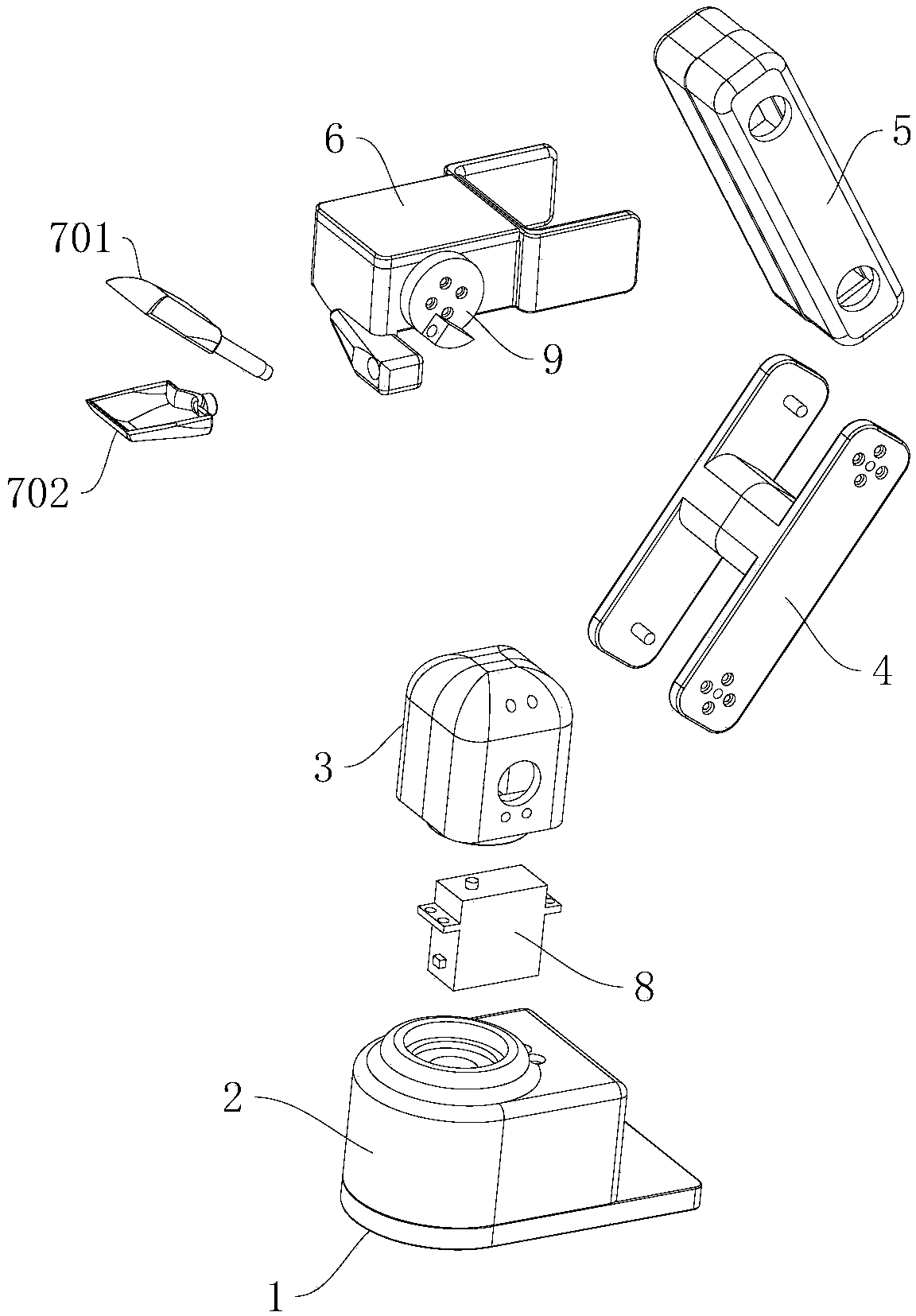

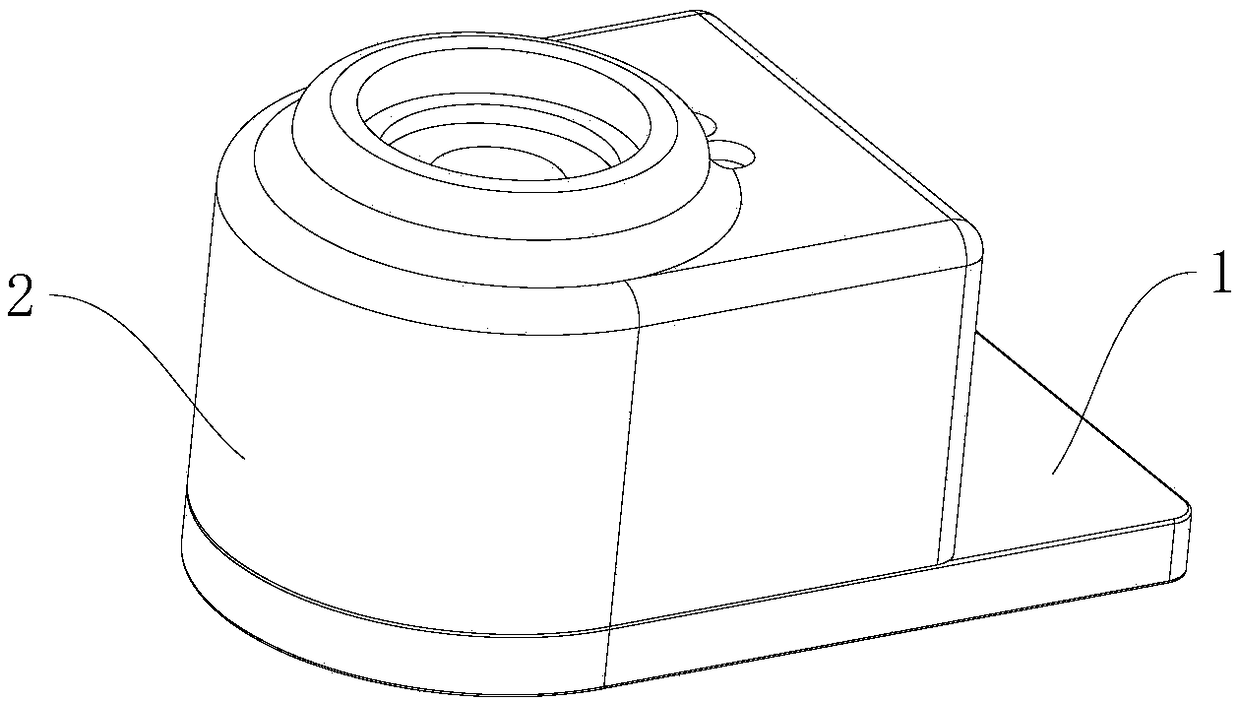

[0062] Such as figure 1 , figure 2 As shown, this embodiment discloses a feeding robot arm, including a base, a robot arm body and a feeding device 7, the bottom end of the robot arm body is rotatably connected to the base, and the feeding device is arranged at the top of the robot arm body. Specifically, the base is provided with a control panel and a bottom steering gear 8, the bottom steering gear is used to drive the mechanical arm to rotate horizontally; After the arm steering gear is driven, it rotates relatively in the vertical direction, the bottom steering gear and the arm steering gear are electrically connected to the control board, and a current sensor is connected between each steering gear and the control board; the feeding device includes mutual The buckled lower spoon body 702 and the upper spoon body 701, the lower spoon body is fixedly connected to the mechanical arm, and the upper spoon body is driven by the feeding servo to rotate in the vertical directio...

Embodiment 2

[0077] This embodiment discloses a specific feeding method and control of a feeding robot arm, which aims to sense the current change of the steering gear through the current sensor, so as to realize the free control of the steering gear and make it easier and more direct to issue various feeding commands.

[0078] Such as Figure 9 As shown, the feeding method of the feeding robot arm disclosed in this embodiment specifically includes the following steps:

[0079] S01: Take the output shaft of the bottom servo as the origin, set the horizontal plane of the feeding device to capture the coordinate point field according to the position of the plate, and calibrate it as (x k ,y k ), k∈N and k≠0; set feeding coordinate point (a, b, c) simultaneously, and abc is constant, and described control panel is provided with memory module, the coordinate information of setting is stored;

[0080] S02: Send a clamping coordinate point signal to the feeding robot arm, the control board con...

Embodiment 3

[0105] This embodiment discloses a specific feeding method and control of a feeding robot arm, which aims to sense the current change of the steering gear through the current sensor, so as to realize the free control of the steering gear and make it easier and more direct to issue various feeding commands.

[0106] In this embodiment, a technical solution different from that in Embodiment 2 is adopted, and the specific differences are:

[0107] In this embodiment, the output axis of the bottom steering gear is not used as the origin, but an arbitrary point is used as the origin, and the output axis coordinates of the bottom steering gear are (x 0 ,y 0 ), in this case, the gripping coordinate signal received by the robotic arm needs to be corrected so that the gripping coordinate point received is (x k ,y k ), k∈N and k≠0 as an example, the specific clamping coordinate point after correction is (x k -x 0 ,y k -y 0 );

[0108] Other processes in this embodiment are the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com