Numerical Simulation Method of Material Interaction Interface Considering Nonlinearity and Strain Rate Effect

An interactive interface, numerical simulation technology, applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problem of not considering nonlinear effects, not reflecting the nonlinear performance of the tangential and normal constitutive relations of the material interface, and not considering the strain. rate effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

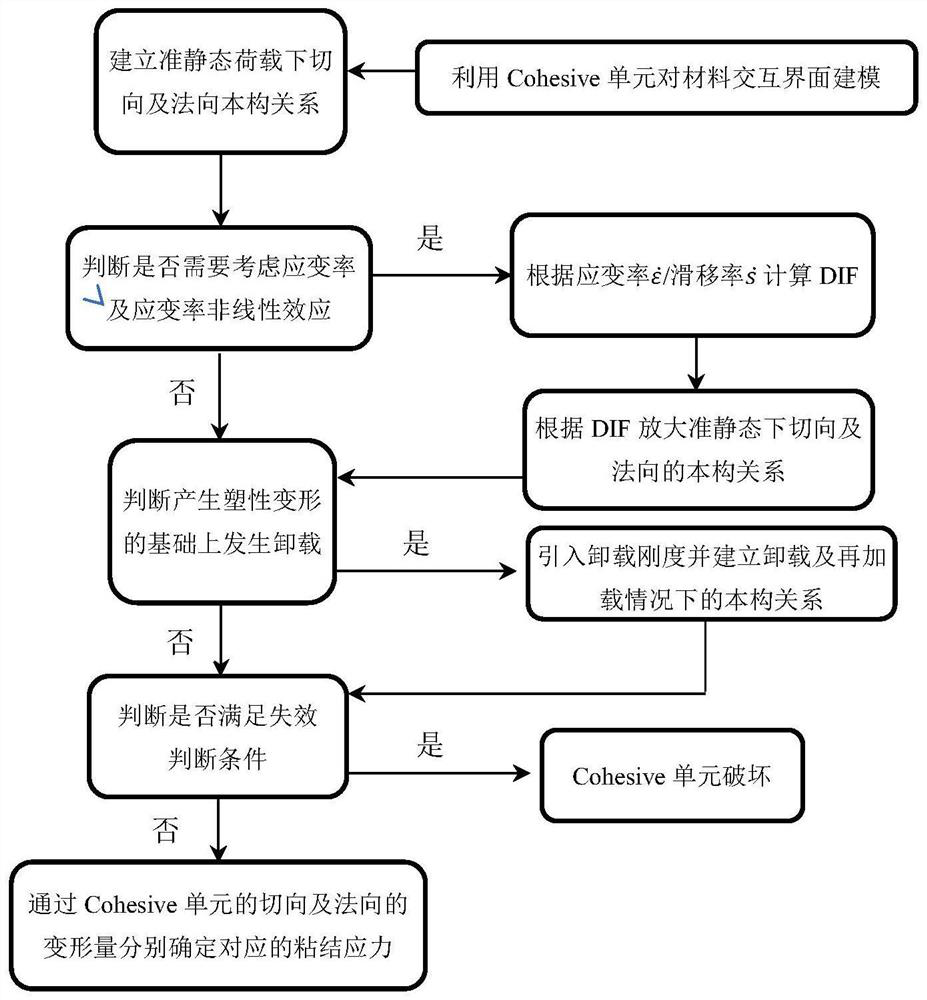

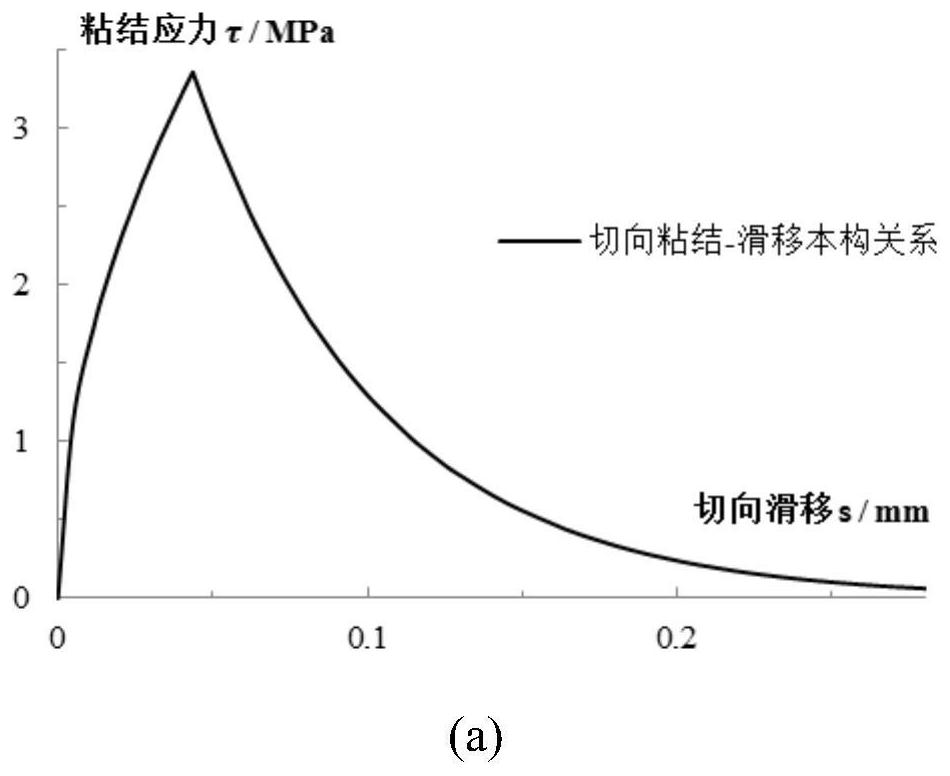

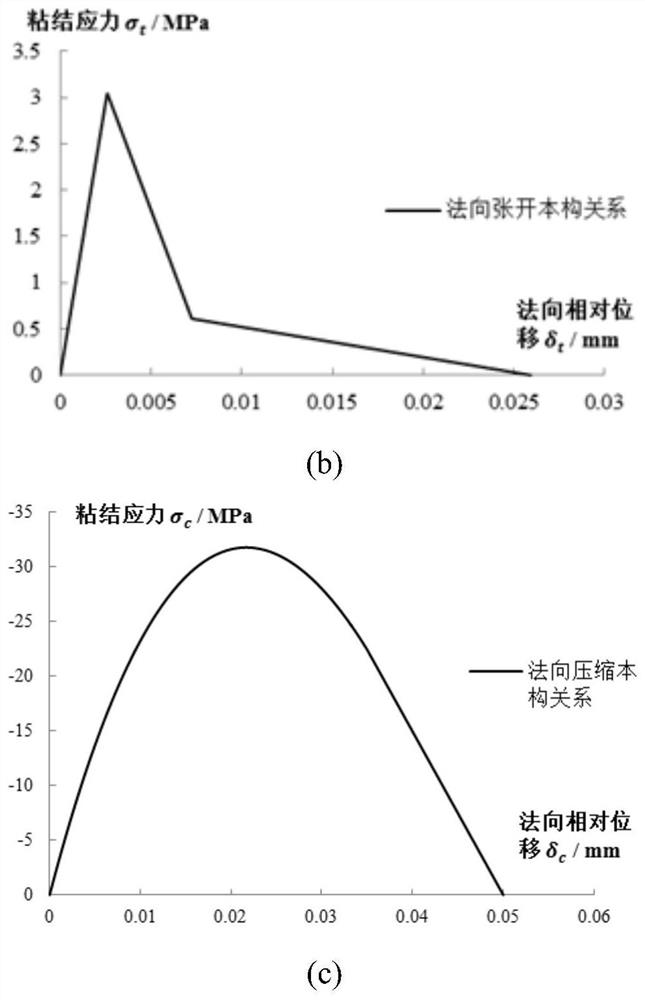

[0077] To conduct finite element research on the bonding performance of two materials, the Cohesive element can be used to simulate the material interaction interface. If the Cohesive unit is placed between the finite element models of the two materials, the tangential and normal properties of the material interface will be reflected by the tangential and normal constitutive relations of the Cohesive unit. In steps (1) to (4) of the method of the present invention, a complete set of ideas for defining constitutive relations of Cohesive units has been proposed. The constitutive relation model formed from step (1) to step (4) is programmed in FORTRAN language to form the user material model subroutine in LS-DYNA, and then embedded into the LS-DYNA solver through the user-defined material module. After inputting certain interface performance param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com