Spiral compression type concrete anti-permeability instrument

A screw compaction and concrete technology, which is applied in the field of concrete impermeability, can solve the problems of easy pollution of the operating environment, large consumption of additional materials, cumbersome operating procedures, etc., and achieve the effects of simple operating procedures, outstanding sealing effect, and avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

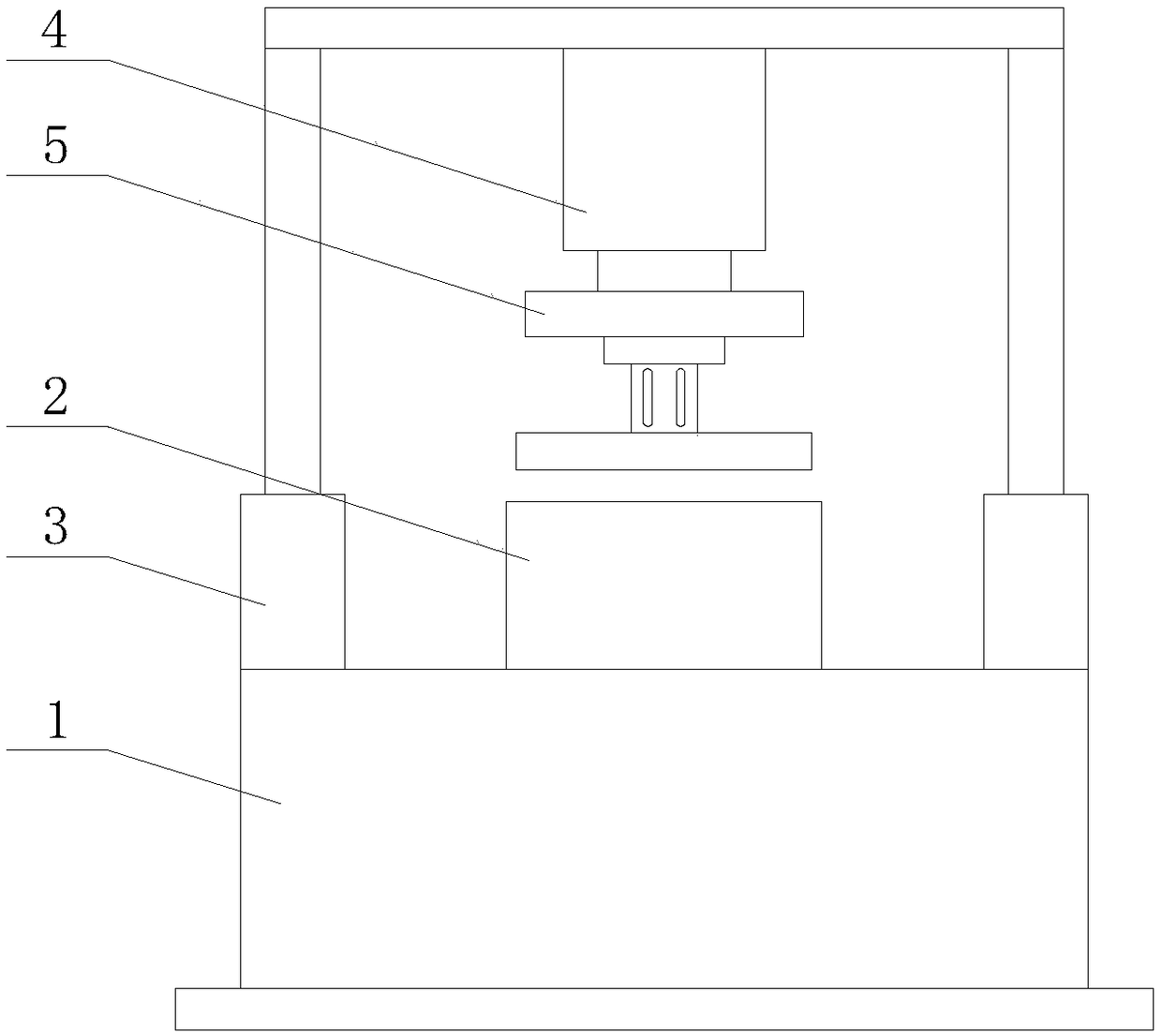

[0020] From figure 1 It can be seen that a screw compaction concrete impermeability instrument of the present embodiment includes a support base 1, a test mold 2 is placed on the upper surface of the support base 1, and a frame 3 is arranged at intervals on the table surface of the support base 1. A press 4 is installed on the top of the frame 3, the frame 3 carries the press 4, and the output end of the press 4 is provided with a screw extruding device 5.

[0021] Heat and melt the cement and butter according to a certain ratio, pour it into a shallow pan, and spread it evenly on the test surface of the test piece. The press 4 works to press down the test piece evenly. A screw extrusion device 5 is used.

[0022] From figure 2 It can be seen that the screw extrusion device 5 is composed of a horizontal fixing seat 51, a gear motor 52, an output shaft 53, an extrusion plate 54 and a sealing rubber sleeve 55. The horizontal fixing seat 51 provides horizontal support, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com