Multi-purpose battery gas production in-situ detection and analysis device

An in-situ detection and analysis device technology, applied in measurement devices, analysis materials, measurement electricity and other directions, can solve the problems of electrode materials, electrolyte development and modification work difficulties, etc., to achieve compact and flexible structure design, conducive to accurate measurement, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

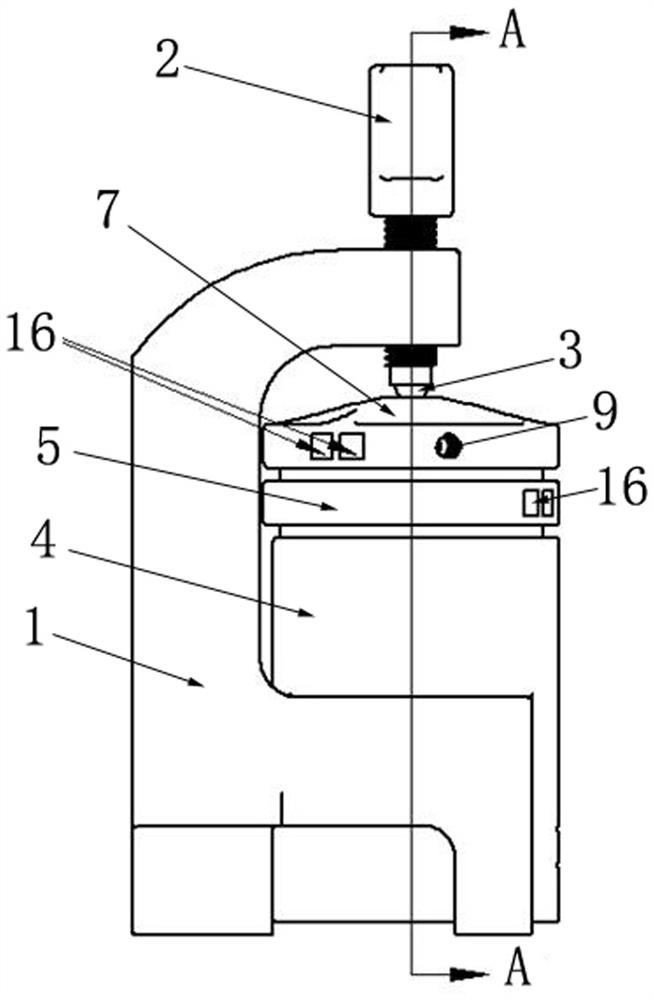

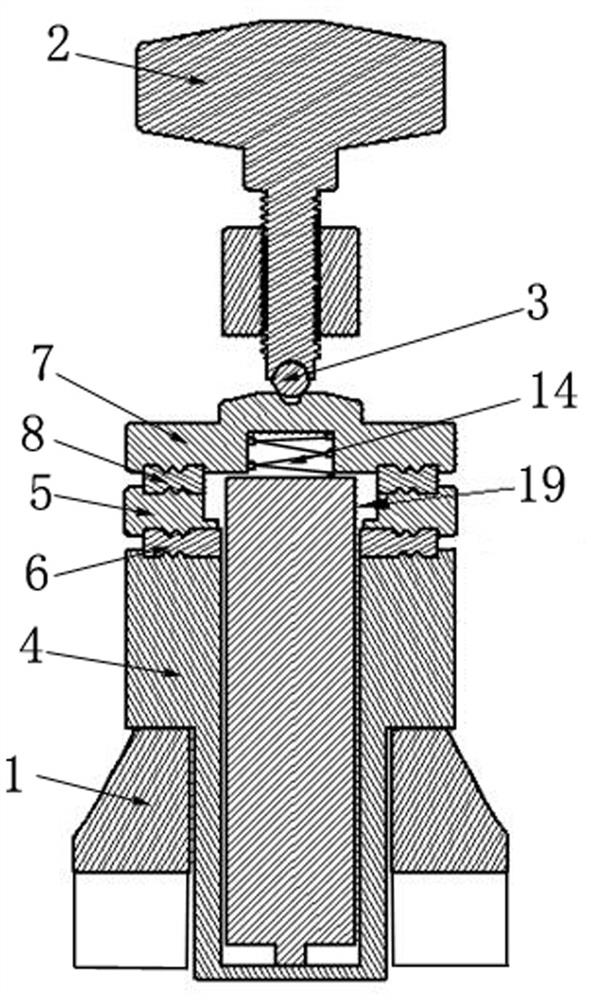

[0030] A multi-purpose battery gas production in-situ detection and analysis device for detecting and analyzing cylindrical batteries, including a bracket 1, the bracket 1 includes a rear support vertical plate, the bottom of the rear support vertical plate is provided with a first support foot, and the rear support vertical plate A front support beam is extended forward on the top of the front support beam, and vertical bolt holes are opened on the front support beam. Support platforms are respectively extended forward on both sides of the lower part of the rear support vertical plate, and the front ends of the two support platforms are respectively extended downward. There are a second support foot and a third support foot; both sides of the bottom of the lower cylinder body 4 are provided with slots that match the upper support platform of the bracket 1, and the lower cylinder body 4 is slidingly mounted on the bottom of the bracket 1 through the slots on it. On the support ...

Embodiment 2

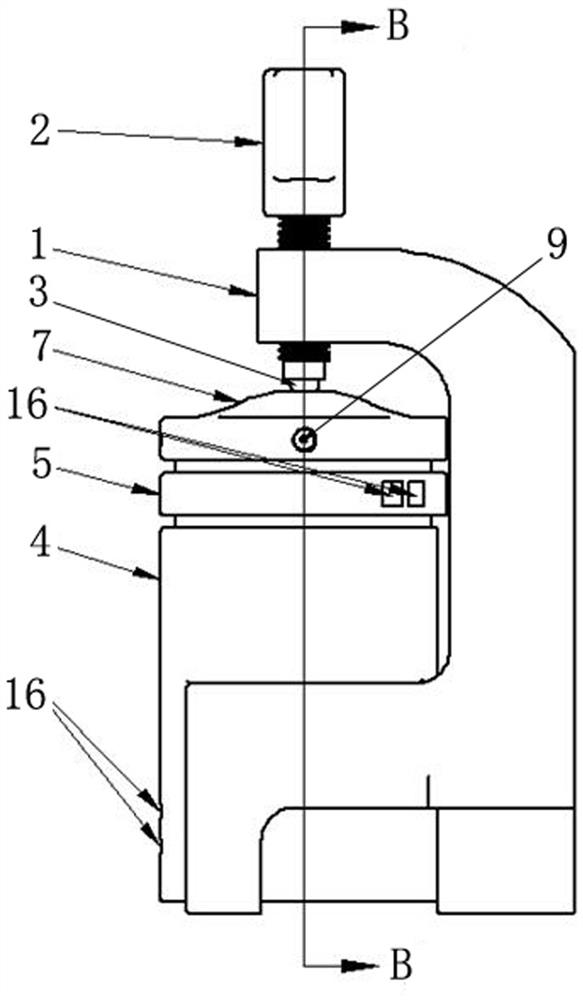

[0033] A multi-purpose battery gas production in-situ detection and analysis device for detecting and analyzing button batteries, including a bracket 1, the bracket 1 includes a rear support vertical plate, the bottom of the rear support vertical plate is provided with a first support foot, and the rear support vertical plate A front support beam is extended forward on the top of the front support beam, and vertical bolt holes are opened on the front support beam. Support platforms are respectively extended forward on both sides of the lower part of the rear support vertical plate, and the front ends of the two support platforms are respectively extended downward. There are a second support foot and a third support foot; both sides of the bottom of the lower cylinder body 4 are provided with slots that match the upper support platform of the bracket 1, and the lower cylinder body 4 is slidingly mounted on the bottom of the bracket 1 through the slots on it. On the support platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com