A Method for Evaluation of Filtration Value Stability of Metal Wire Woven Dense Mesh

A technology of metal wire weaving and dense mesh, which is applied in the direction of measuring devices, suspension and porous material analysis, scientific instruments, etc., to achieve the effects of exquisite design, low production cost, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

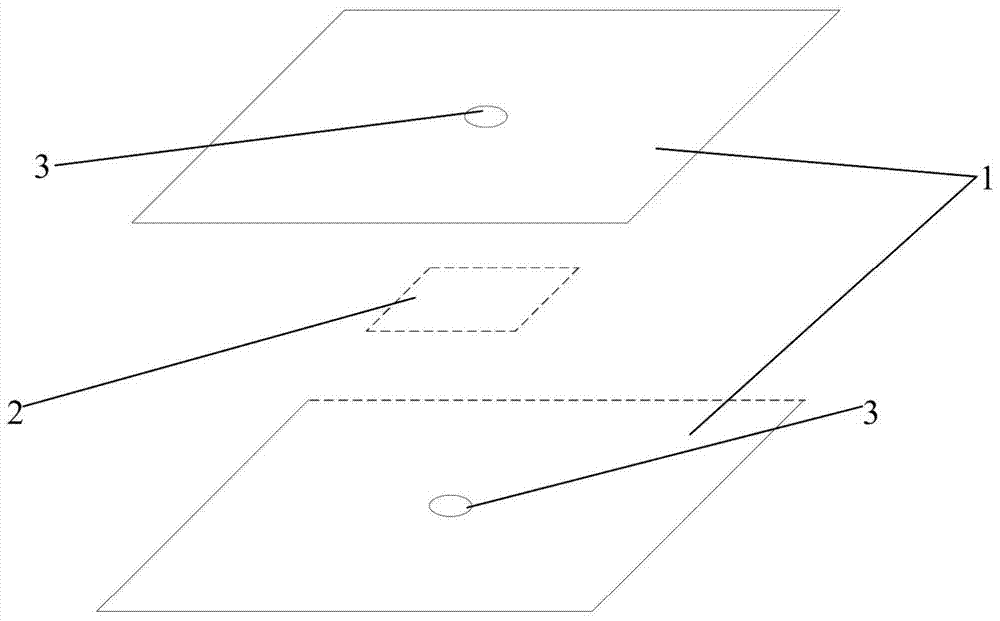

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0023] Such as figure 1 As shown, the present invention provides a method for evaluating the stability of the filter value of a metal wire weaving dense mesh, comprising the steps of:

[0024] Step 1, the metal wire weaving dense mesh 2 is fixed between two sheet-like carriers 1 with smooth surfaces, and the sheet-like carriers 1 are air-tight materials, such as aluminum foil boards or wrapping boards, which can be considered as air-tight materials , Another example is a stainless steel plate, aluminum plate or copper plate with a thickness of 0.25mm. The thickness of these materials can make the stainless steel plate, aluminum plate or copper plate almost airtight, which can be considered as an airtight material. Each of the two sheet carriers 1 is provided with a through h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com