Metal sealing valve seat and wear-resisting ball valve

A metal-sealed, wear-resistant ball technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of easy loosening of metal-sealed valve seats, affecting sealing performance, ball locking, etc. The possibility of dead damage, prolonging the service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

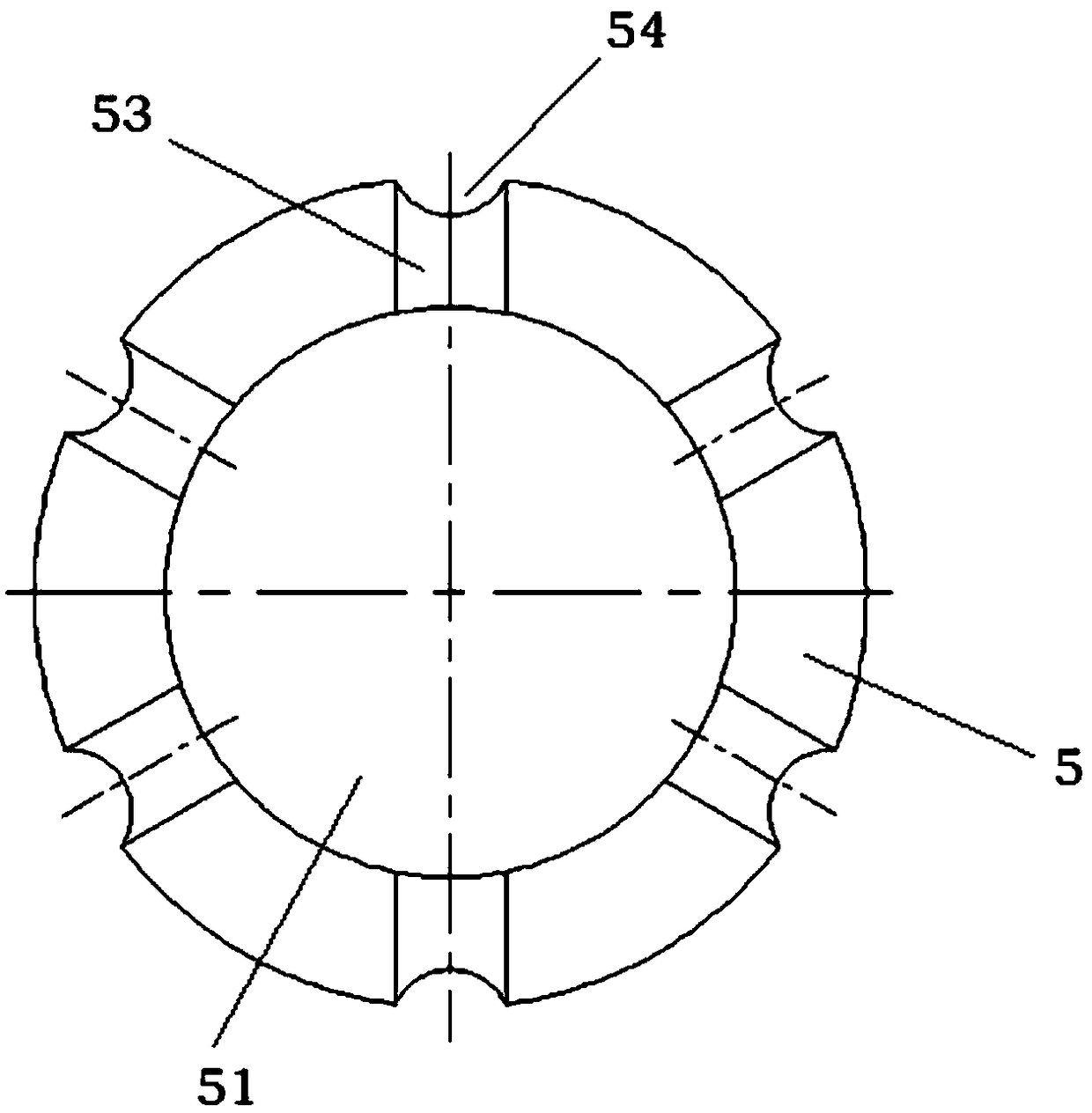

[0027] like figure 1 , 2 , 3, the metal sealing valve seat disclosed in the present invention includes a valve seat body 5, the valve seat body 5 has an axial passage 51, one end of the valve seat body 5 is provided with a valve seat sealing surface 52, and the valve seat sealing surface 52 is a spherical surface And it is a metal sealing surface. The end face of the other end of the valve seat body 5 has at least one radial groove 53, and the outer circular surface of the valve seat body 5 has at least one axial groove 54. The number of the radial grooves 54 is equal to the number of the radial grooves 53 ;

[0028] The valve seat body 5 is provided with radial grooves 53 and axial grooves 54, which mainly play the role of connecting the flow channel and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com