Alarm device for wear of friction sheet

A technology of an alarm device and a friction plate, which is applied in the field of an alarm device and an alarm device for friction plate wear, can solve the problems of being unable to be used again and insufficient applicability, and achieve the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

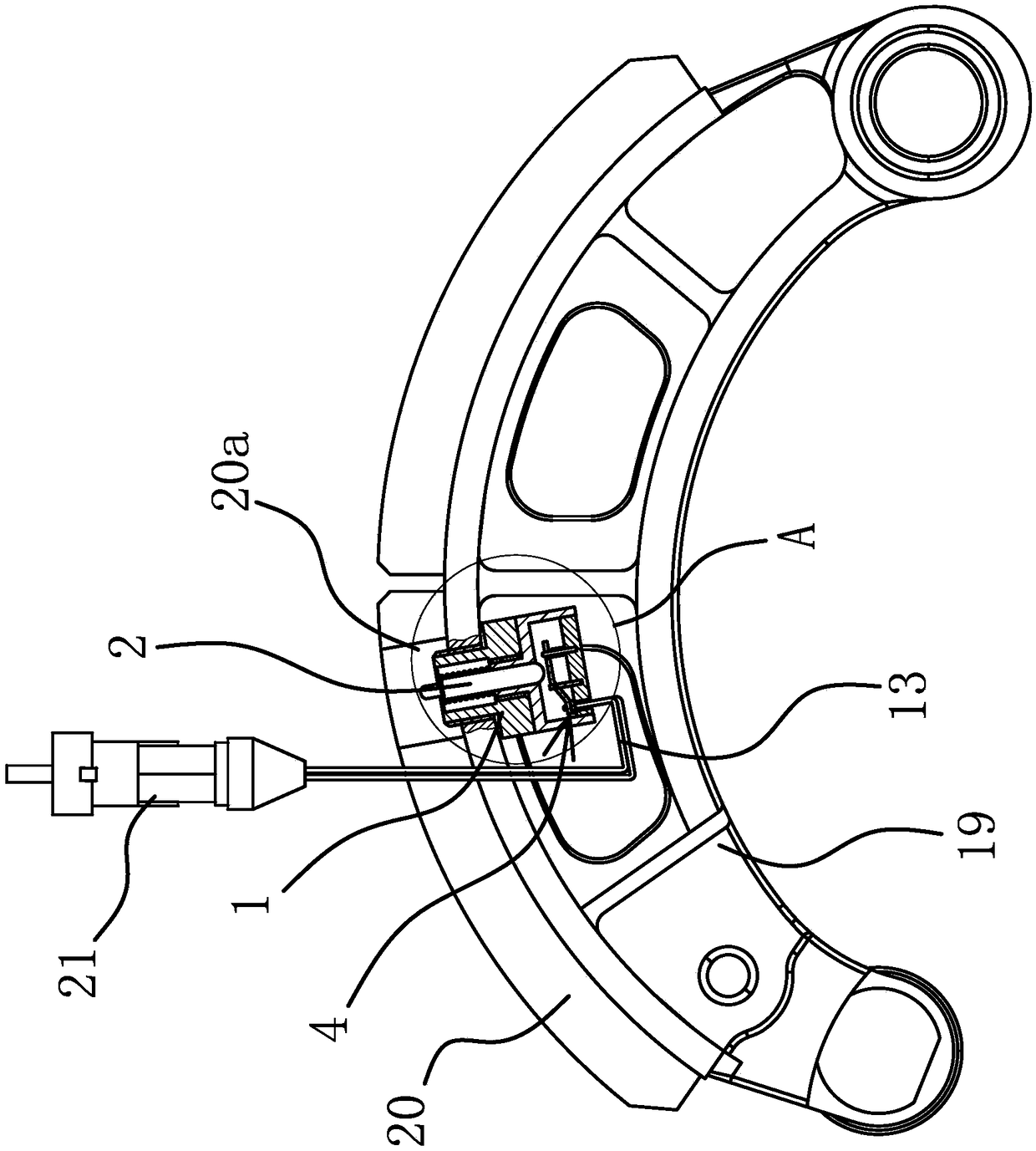

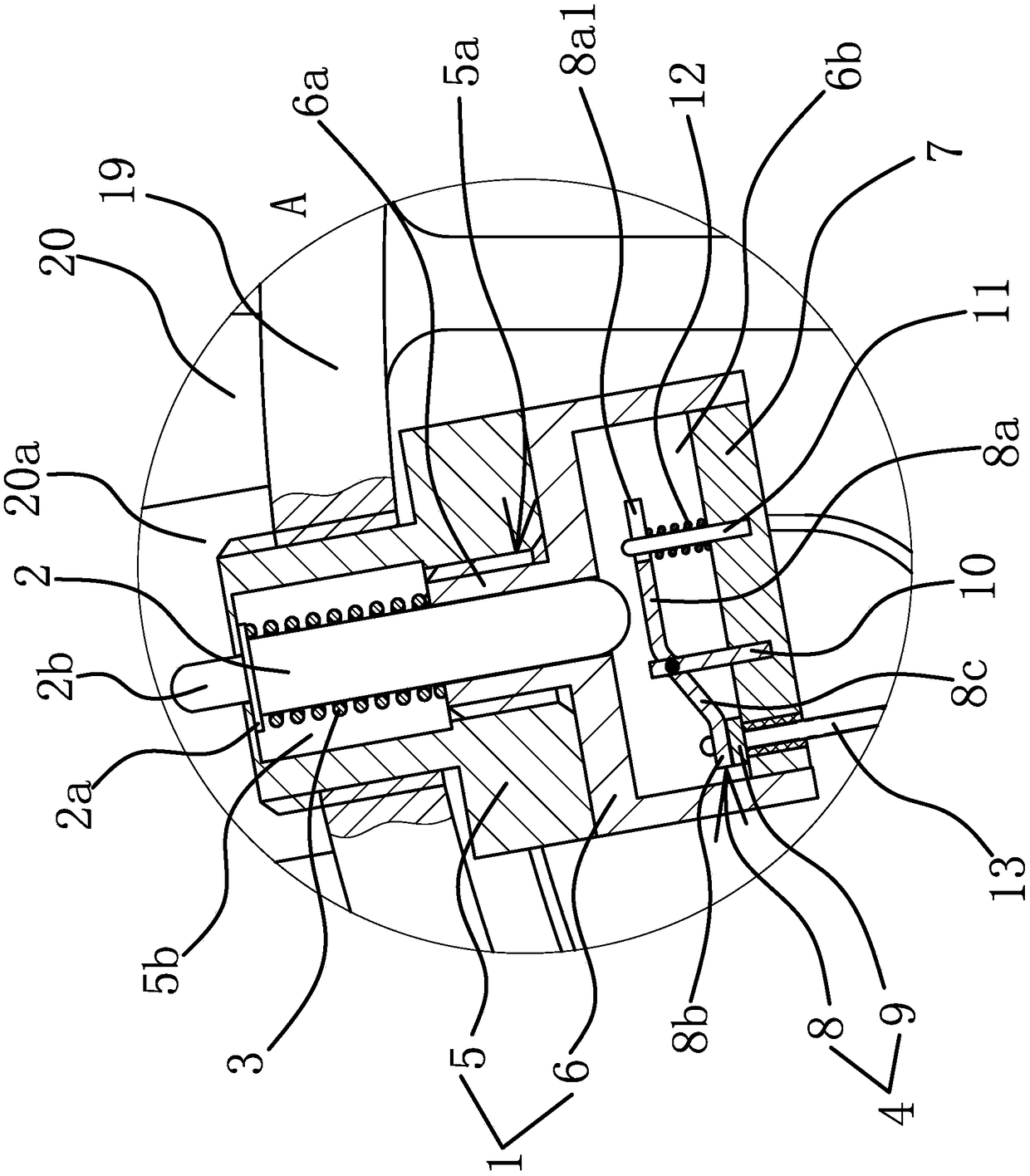

[0036] Such as figure 1 and figure 2 As shown, an alarm device for friction lining wear includes a fixed head 1 , a switch element 4 , a push rod 2 and a positioning spring 3 . The upper end of the fixed head 1 is the installation end, the push rod 2 is penetrated in the fixed head 1 and the push rod 2 can move up and down, there is a gap between the push rod 2 and the trigger element, when the push rod 2 moves down, the switch element can be triggered 4. The outside of the push rod 2 is provided with an abutment portion 2a, and the fixed head 1 is provided with an abutment surface 1a facing the lower end surface of the abutment portion 2a. On the lower end face of the resting part 2a, the lower end of the positioning spring 3 abuts against the inner wall of the fixed head 1, and the upper end face of the abutting part 2a abuts against the inner top wall of the fixed head 1 under the elastic force of the positioning spring 3, and The lower end of the push rod 2 always has ...

Embodiment 2

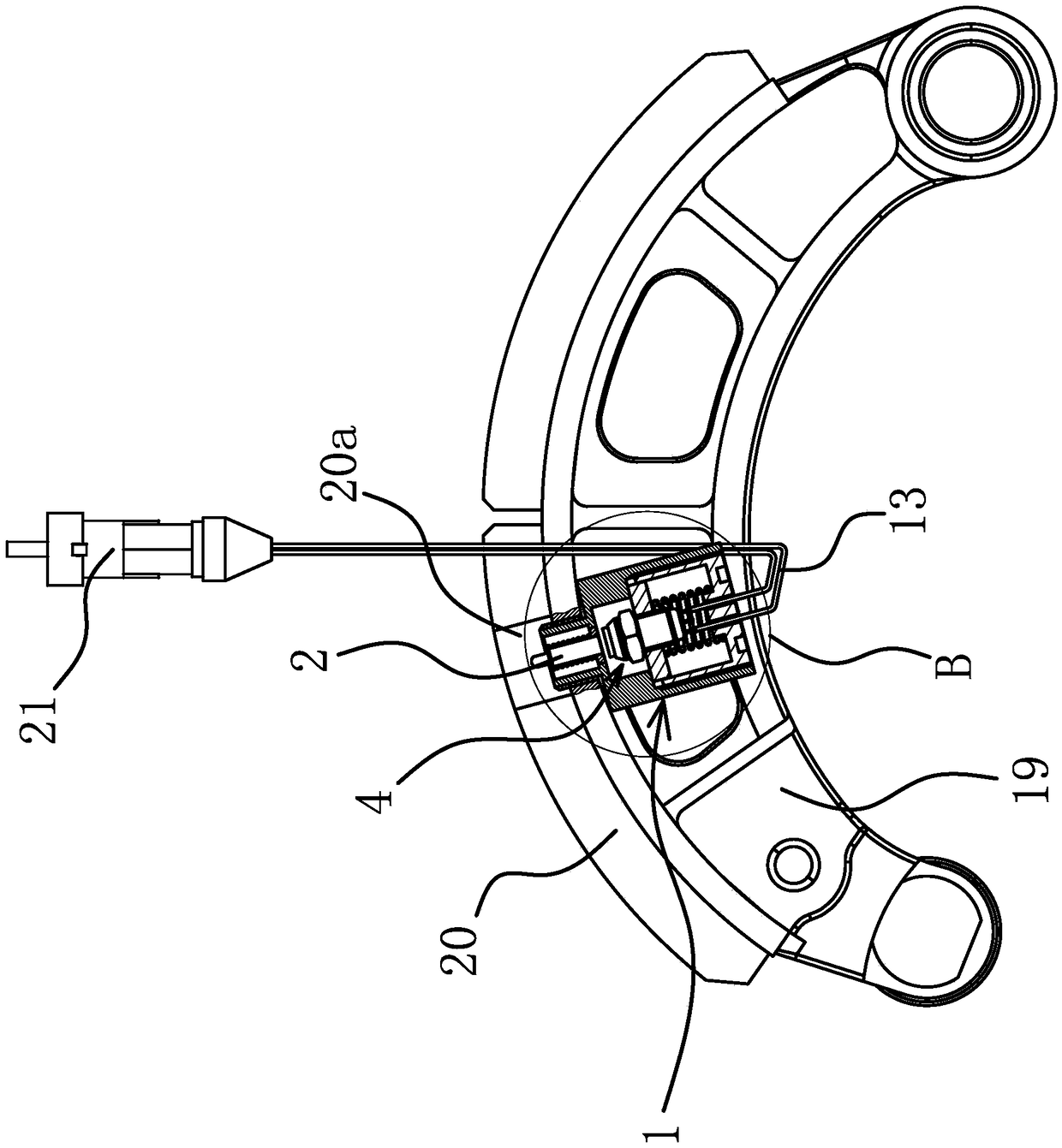

[0045] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3 and Figure 4 As shown, in this embodiment, the fixing head 1 includes an upper connecting body 5 and a lower connecting body 6 , the outer upper end of the upper connecting body 5 has external threads, and the lower connecting body 6 is screwed to the lower end of the upper connecting body 5 . The lower end surface of the upper connecting body 5 is provided with a positioning cavity 5c, the lower connecting body 6 is cylindrical with an upper end open, the lower connecting body 6 is screwed in the positioning cavity 5c, and the lower end surface of the lower connecting body 6 is provided with a slot 6c.

[0046] Such as Figure 4 As shown, the switch element 4 is an inching switch, and the switch element 4 includes a cylindrical shell 14 and an inching button 15 arranged on the upper end of the shell 14. The inching button 15 is located direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com