Water inlet section structure of multiple-stage centrifugal pump with fish-mouth suction port

A technology of water inlet section and suction port, which is applied in the field of water inlet section structure of multistage centrifugal pumps, can solve problems such as energy loss, reduction of hydraulic performance of multistage centrifugal pumps, and smaller liquid flow space, so as to reduce energy loss, Effect of reducing disturbance and improving hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

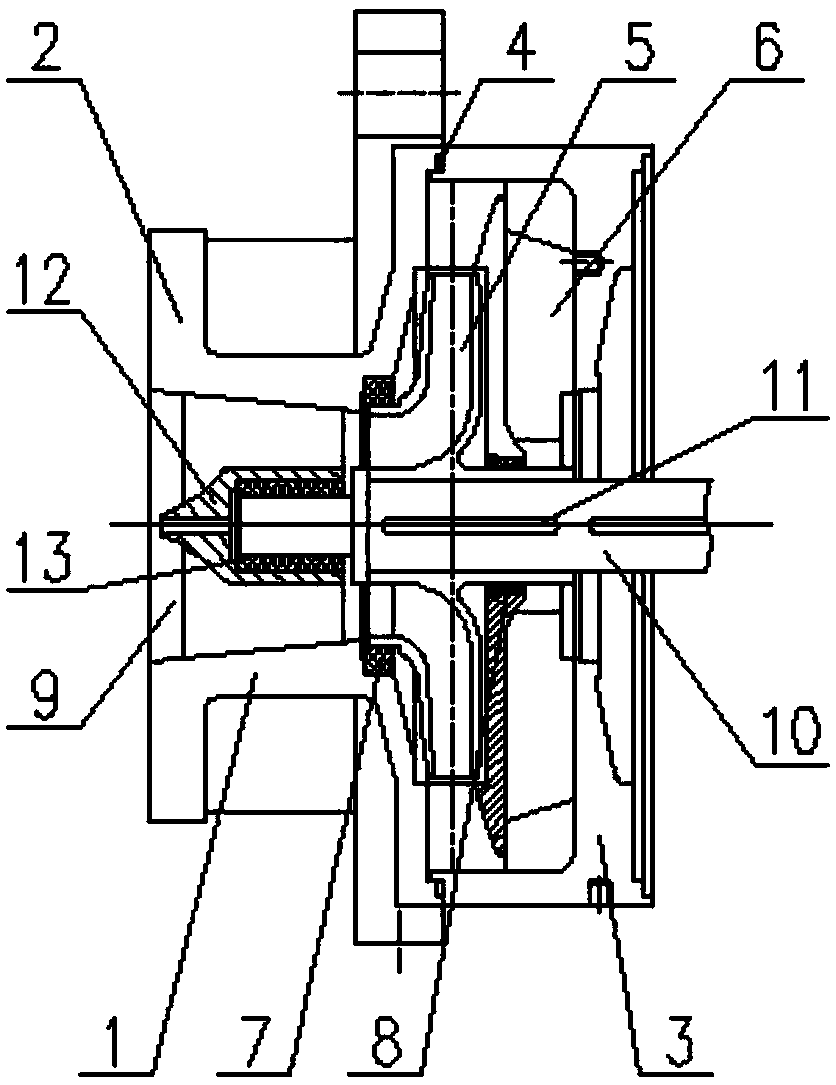

[0015] figure 1 It is a sectional view of the present invention. Since the flow losses inherent in multistage centrifugal pumps are well known and constitute a problematic and unpredictable source of flow losses, changes in the design of the inlet section structure are required. Such as figure 1 As shown, the present invention discloses a water inlet section structure of a multistage centrifugal pump whose suction port is a fish mouth type, including a water inlet section pump body 1 and a first-stage middle section pump body 3 . The pump body 1 of the water inlet section and the pump body 3 of the middle stage of the first stage are sleeved on the pump shaft 10 . The second end of the pump body 1 of the water inlet section is equipped with a first-stage middle-section pump body 3 . An O-ring sealing groove 4 is provided between the second end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com