Stainless steel folded water blocking structure construction method and steel cutting device

A cutting device and construction method technology, applied in the direction of manufacturing tools, roof drainage, roof engineering tools, etc., can solve the problems of poor sealing effect of joints, roof leakage, and poor flooding effect, etc., to improve work efficiency Efficiency and working range, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

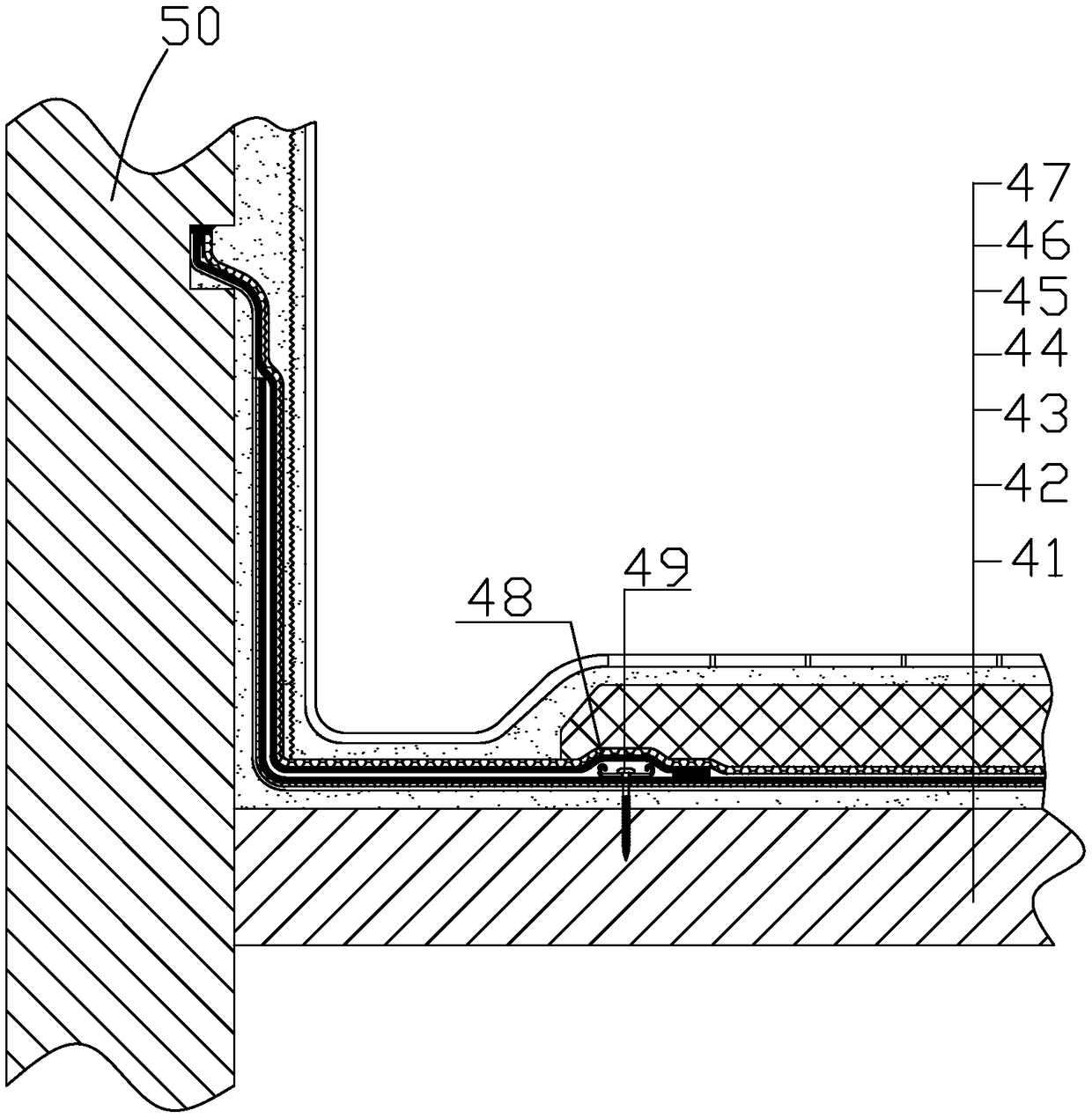

[0053] A construction method for stainless steel flanging and flashing according to the present invention comprises the following steps:

[0054] (1) Construction preparation

[0055] a. Determine the construction plan: through the analysis and calculation of the roof structure, prepare the construction plan, implement it after approval, and adjust the construction sequence according to the implementation situation, and do a good job of technical disclosure;

[0056] b. Stakeout measurement: Eject the control line with a level meter and a protractor, unify the flooding height of the roof, and mark the set height position of the wall 50, and follow the direction of the roof to the roof according to the statistical data of rainfall Select the starting point of the flashing location and set a mark at the starting point;

[0057] (2) Surface cleaning of structural layer 41

[0058] First, use a wire broom to clean the surface of the structural layer 41 of the roof, and use a sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com