A method for preparing needle coke from kerosene co-refining residue

A technology of kerosene co-residue and needle coke, applied in coking ovens, petroleum industry, coking carbonaceous materials, etc., can solve the problems of high reaction pressure, high energy consumption, complex process, etc., and achieve short time consumption and low pressure , The effect of continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

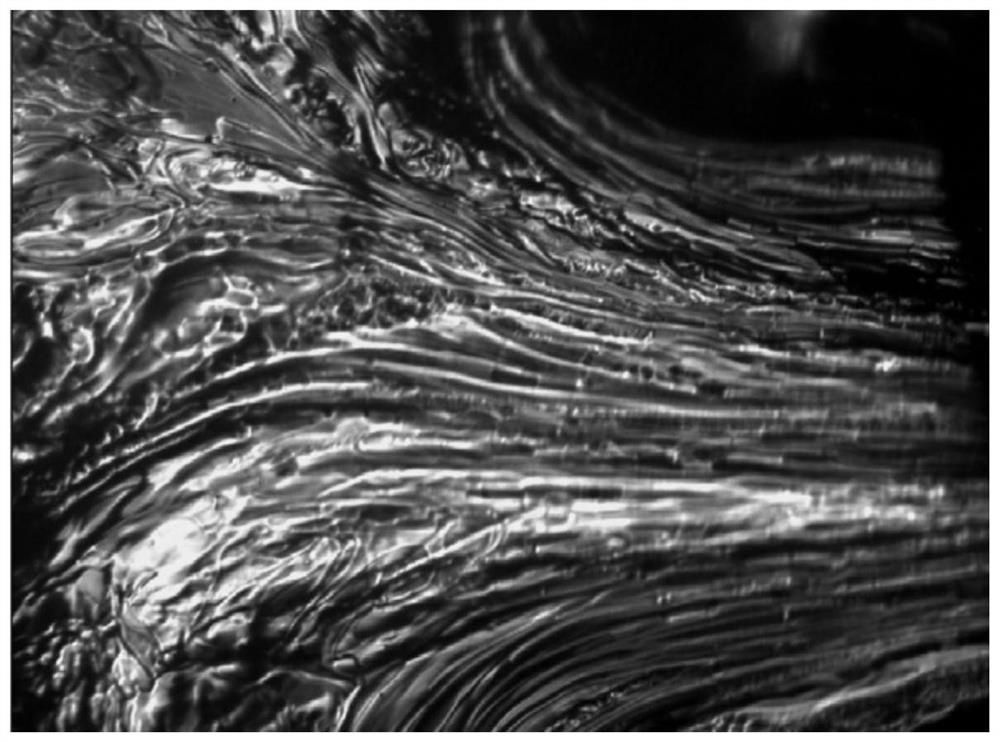

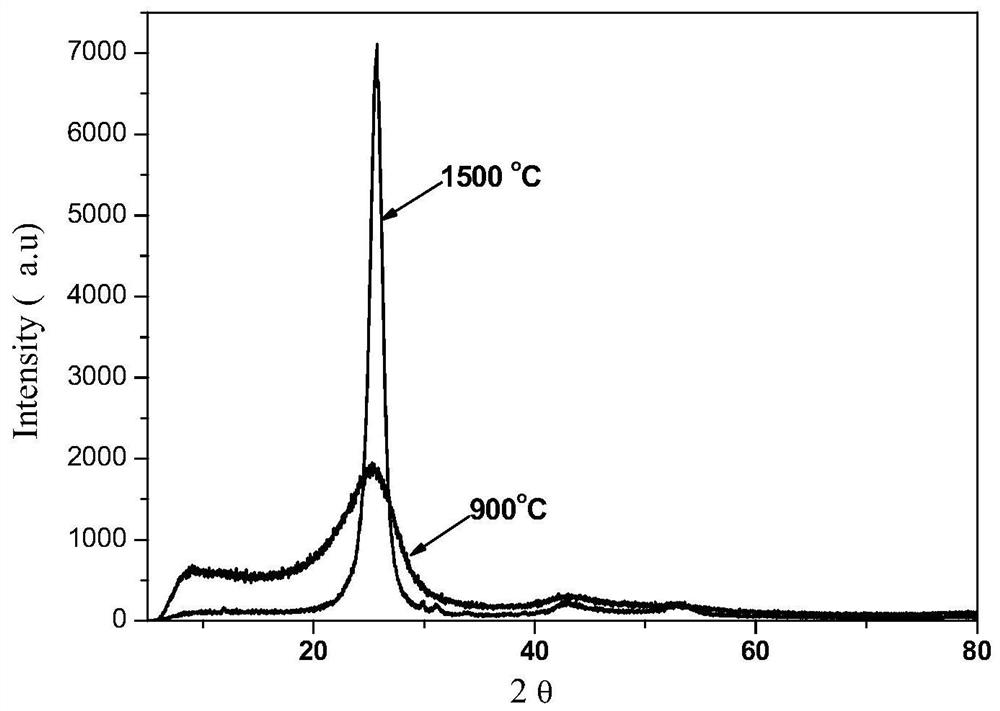

[0027] 100g of kerosene co-refining residue (450,000 tons / year kerosene co-refining residue of Yanchang Petroleum Group, asphaltene content of 50wt%, ash content of 28wt%) and 400g of toluene and n-heptane mixed solvent (mass ratio of 1:1 ) uniformly mixed at room temperature and extracted at 150° C. for 2 hours, asphaltenes with a softening point of 95° C., no ash, and a molecular weight distribution of 300-600 were isolated, and the yield of the asphaltenes was 47%.

[0028] Put the asphaltene into the heating furnace, under the protection of normal pressure nitrogen, heat to 430 ℃ at 5 ℃ / min, and keep it for 1 hour; Hours, 18g needle coke was obtained with a true density of 2.18g / cm 3 , The coefficient of thermal expansion CTE is 0.95×10 -6 / °C, sulfur content 0.02wt%, anhydrous, ash-free, superior to the domestic standard of coal-based needle coke.

Embodiment 2

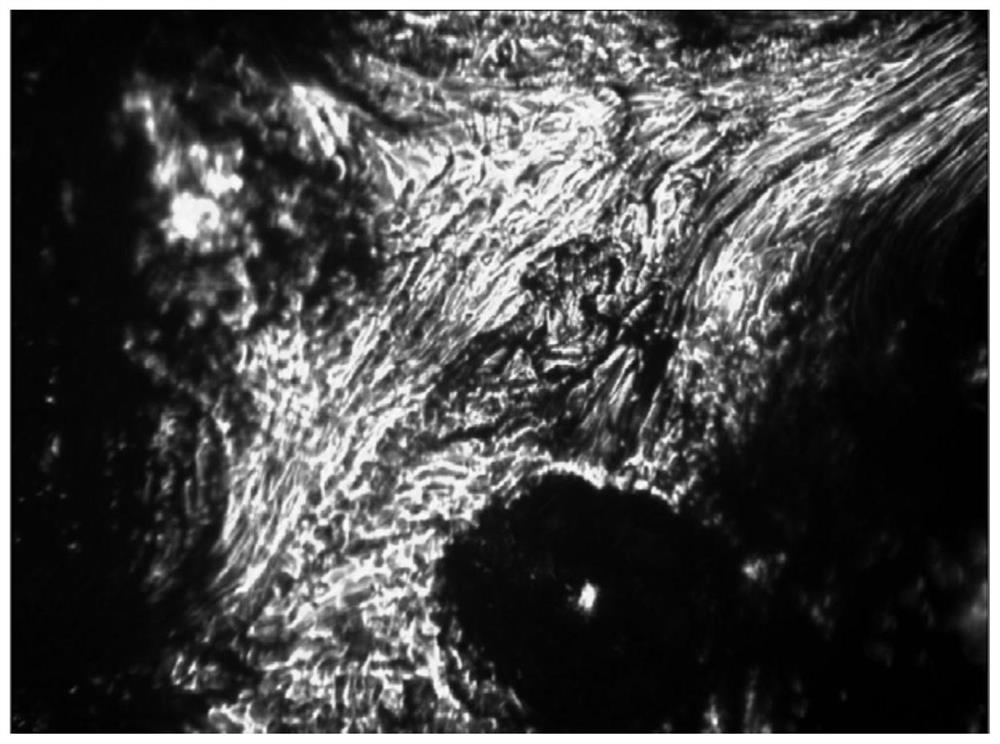

[0030] 100g of kerosene co-refining residue (450,000 tons / year kerosene co-refining residue of Yanchang Petroleum Group, asphaltene content of 48wt%, ash content of 29wt%) and 600g of mixed solvent of xylene and n-hexane (mass ratio of 3:1 ) uniformly mixed at room temperature and extracted at 110° C. for 5 hours, then extracted and separated to obtain asphaltenes with a softening point of 80° C., no ash, and a molecular weight distribution of 300-550. The yield of asphaltenes was 41%.

[0031] Put the asphaltene into the heating furnace, under the protection of 0.3MPa nitrogen, heat at 3°C / min to 420°C, and keep it for 2 hours; , get 16g needle coke, its true density is 2.13g / cm 3 , The coefficient of thermal expansion CTE is 0.96×10 -6 / °C, sulfur content 0.016wt%, anhydrous, ash-free, superior to the domestic standard of coal-based needle coke.

Embodiment 3

[0033]100g of kerosene co-refining residue (450,000 tons / year kerosene co-refining residue of Yanchang Petroleum Group, asphaltene content of 45wt%, ash content of 27wt%) and 1000g of mixed solvent of toluene and n-hexane (mass ratio is 4:1) Uniformly mixed at room temperature, extracted at 70°C for 12 hours, and separated to obtain asphaltenes with a softening point of 70°C, no ash, and a molecular weight distribution of 310-580. The yield of the asphaltenes is 40%.

[0034] Put the asphaltene into the heating furnace, under the protection of 0.2MPa nitrogen, heat at 5°C / min to 450°C, keep it for 5 hours; then under the protection of 0.2MPa nitrogen, raise the temperature to 1300°C at 10°C / min, and calcined for 1 hour, Obtain 15g needle coke, its true density is 2.16g / cm 3 , The coefficient of thermal expansion CTE is 0.95×10 -6 / °C, sulfur content 0.018wt%, anhydrous, ash-free, superior to the domestic standard of coal-based needle coke.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com