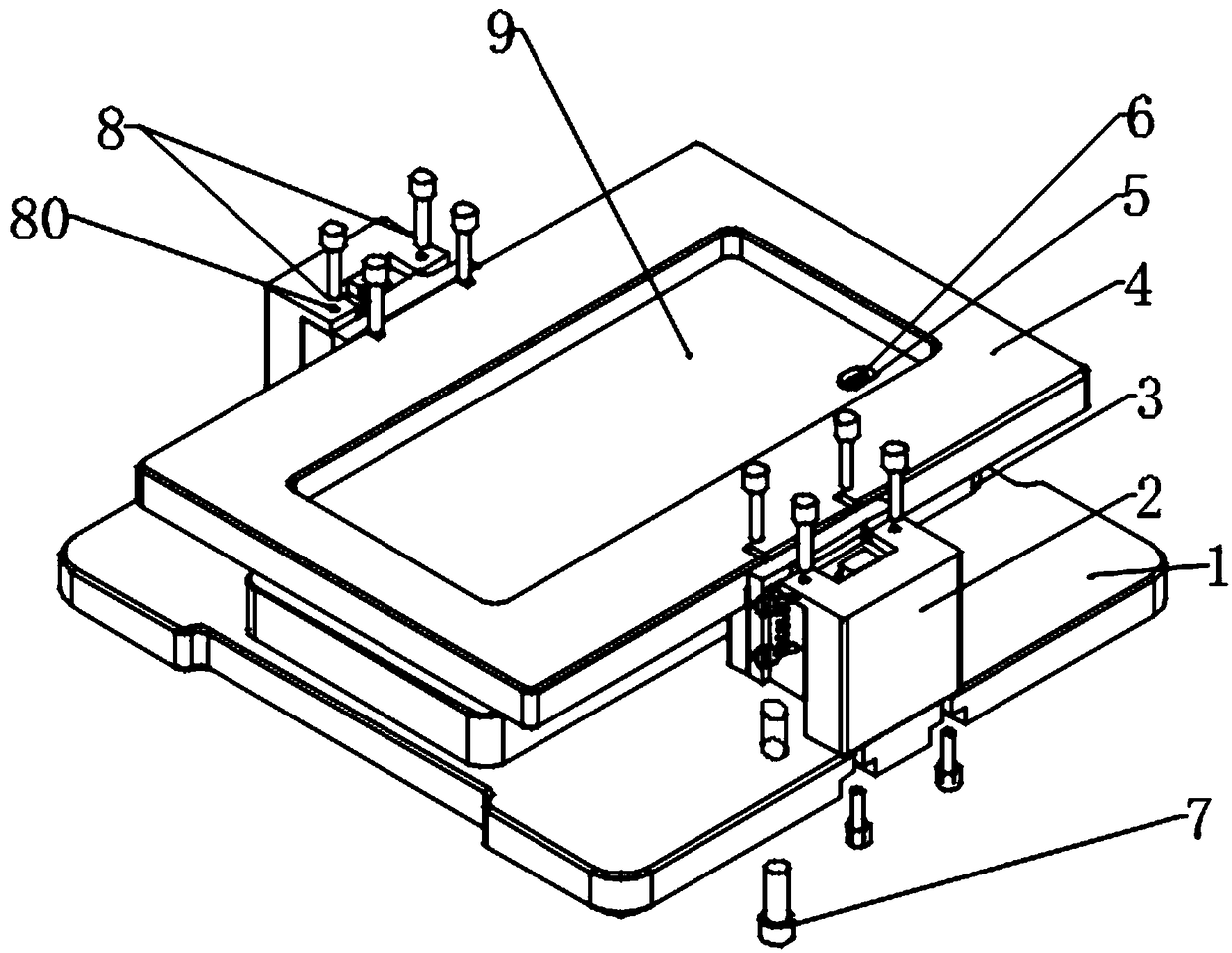

Push type auxiliary material laminating device

An auxiliary material lamination and pressing technology, applied in lamination device, lamination auxiliary operation, lamination and other directions, can solve the problems of easy displacement of auxiliary materials, low precision of lamination, poor control of the depth of auxiliary material grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of the following embodiments is used to help understand the invention, but does not constitute a limitation to the invention.

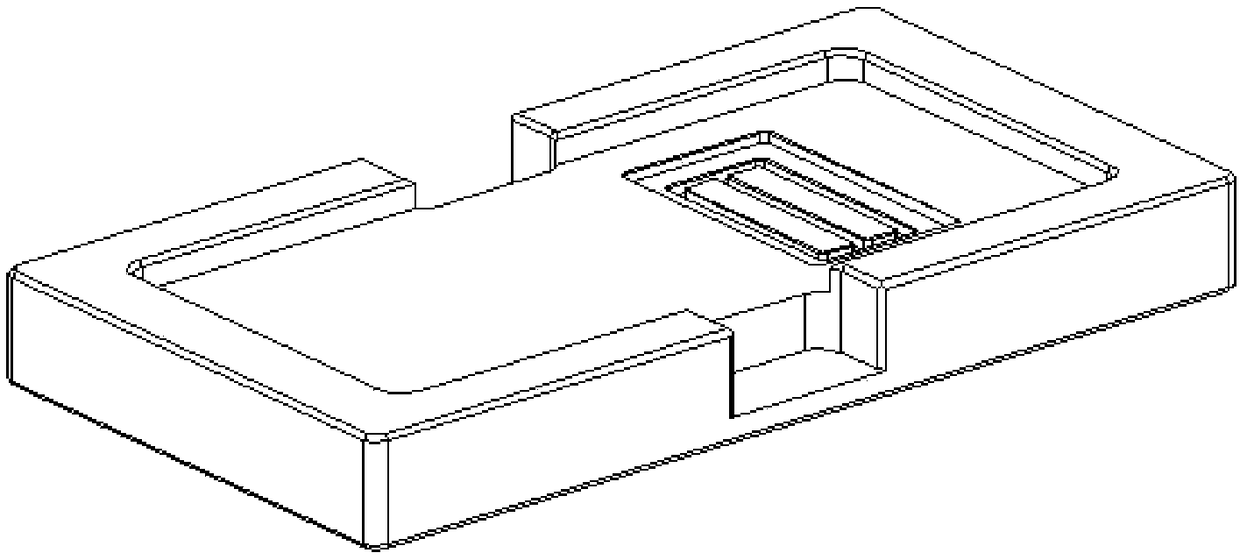

[0024] figure 1 For the existing auxiliary material assembly technology, vacuum negative pressure is used to absorb the auxiliary material, and the glass is positioned at right angles to the side of the fixture, and then the auxiliary material is pressed downward. This kind of assembly jig has high requirements on the operation of the operator. If there is a little carelessness, the glass will come into contact with the auxiliary materials in advance, resulting in poor bonding. In addition, this kind of fixture has low fitting accuracy, and the depth of the auxiliary material groove is not easy to control. The groove depth is smaller than the thickness of the auxiliary mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com