Hot melt sleeve and production tool, production method, storage and transport method and construction method

A hot-melt sleeve and sleeve technology, which is applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, mechanical equipment, etc. The problems of complex construction methods and other problems are solved, and the effect of high construction efficiency, small land occupation and simple construction method is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

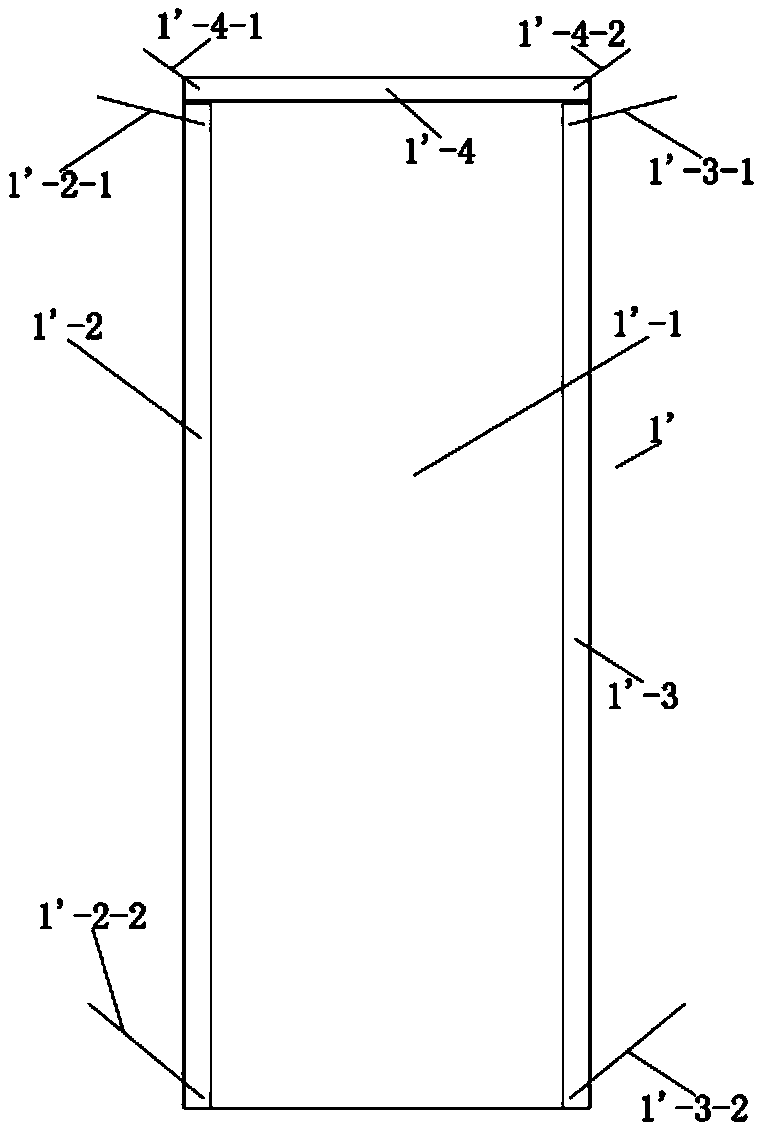

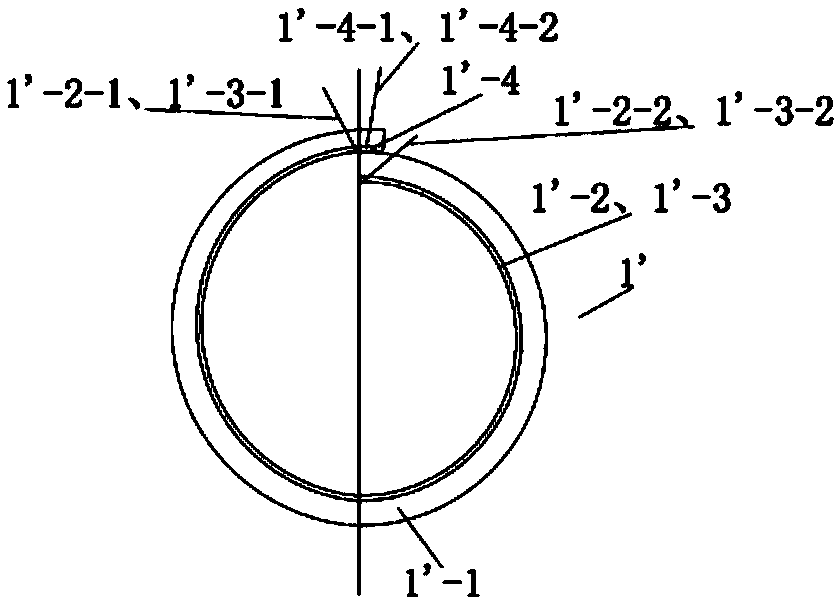

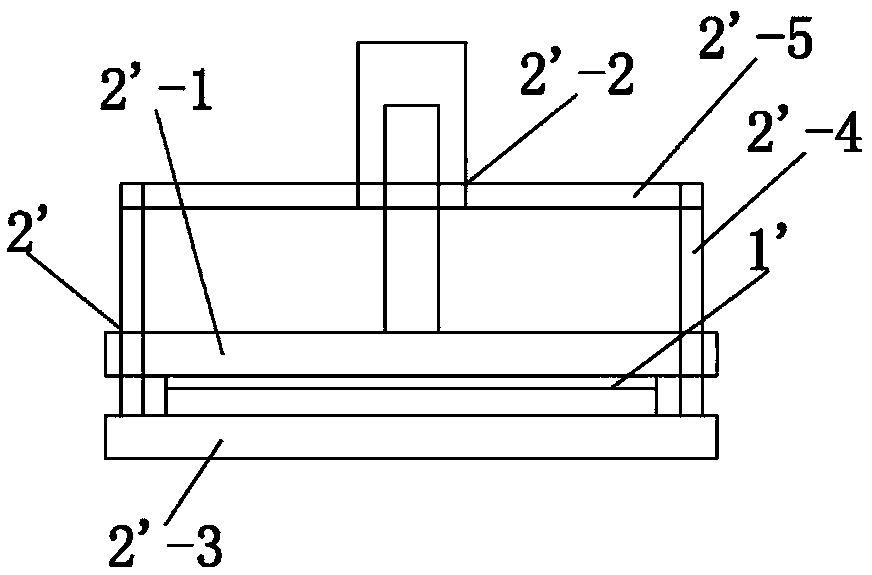

[0176] like Figure 5 to Figure 6 As shown, this embodiment provides a hot-melt sleeve, including a seamless rubber sleeve 1-1. The edge of the inner surface of one end of the seamless rubber sleeve 1-1 is provided with a first mesh strip 1-2 along the circumference, and the two ends of the first mesh strip 1-2 are close to each other. One end of the strip 1-2 is provided with a first live wire electrode 1-2-1, and the other end of the first mesh strip 1-2 is provided with a first neutral wire electrode 1-2-2. The edge of the inner surface of the other end of the seamless rubber sleeve 1-1 is provided with a second mesh strip 1-3 along the circumference, and the two ends of the second mesh strip 1-3 are close to each other. One end of the strip 1-3 is provided with a second live line electrode 1-3-1, and the other end of the second mesh strip 1-3 is provided with a second neutral line electrode 1-3-2.

[0177] Various improvements of this embodiment are described in detail b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com