Novel film lamination device for packaging boards

A film covering device and a new packaging technology, which is applied in the field of new packaging board film covering devices, can solve the problems of large workshop space, poor water absorption and waterproof performance, and high production costs, so as to reduce occupied space, improve production efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

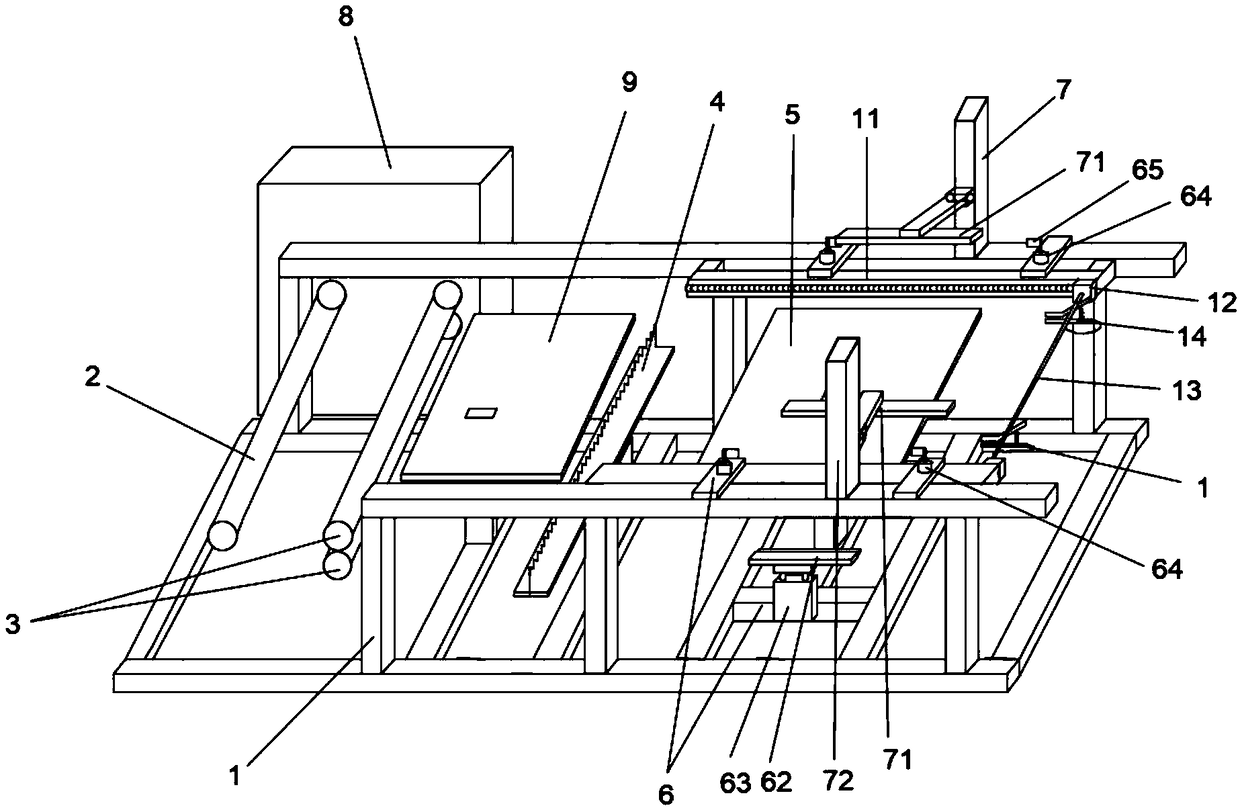

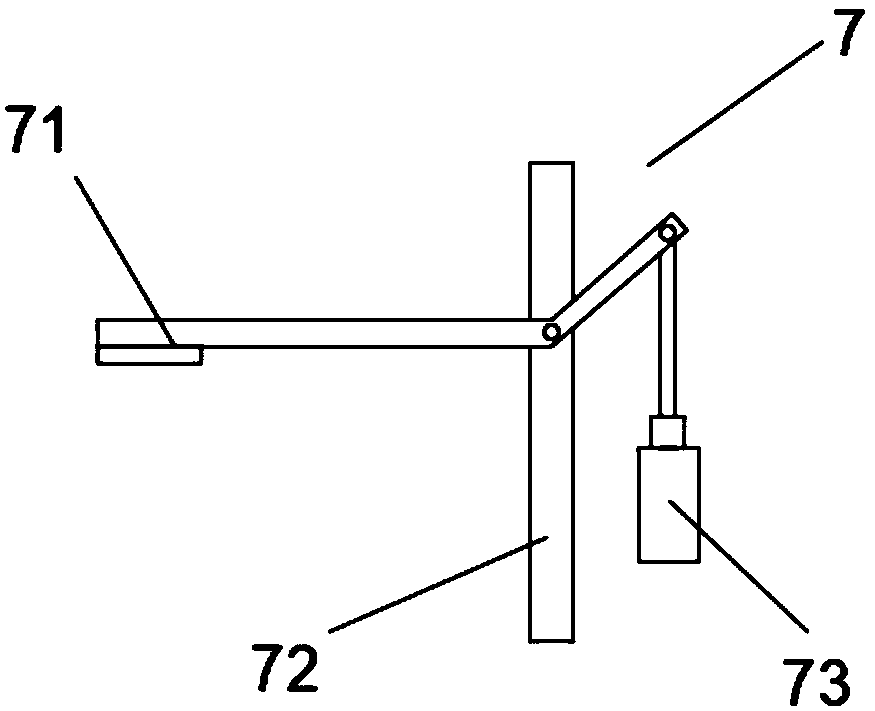

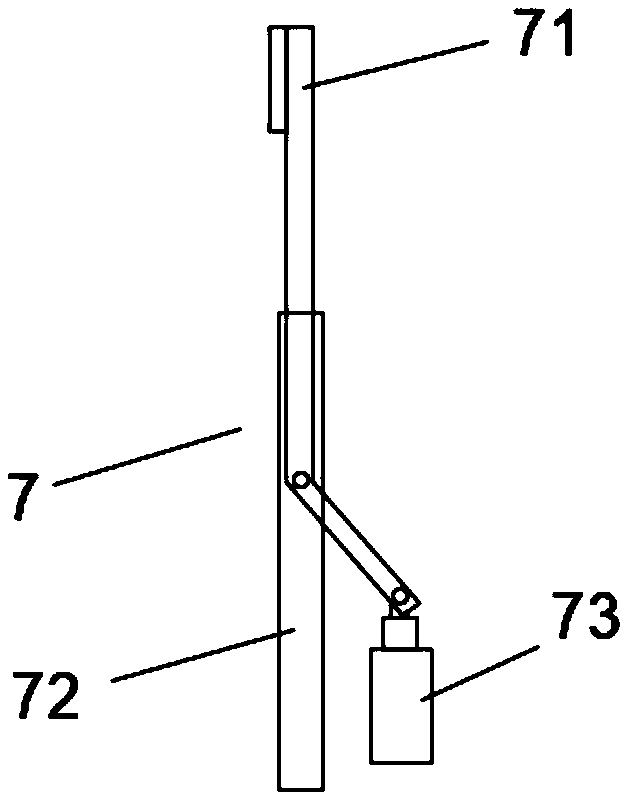

[0026] see figure 1 , a new type of packaging board laminating device, which includes a frame 1, the frame 1 is composed of several beams, longitudinal beams and vertical beams to form a cube structure, the length direction from one end to the other end of the frame 1 ( figure 1 Described from the left end to the right end) is provided with the fixing roller 2 that is used for fixing plastic film roll roll in sequence, is used for the rubber cover roller 3 that coats glue solution on the upper surface of the plastic film that is drawn out, is used for the cutting that plastic film is cut off. The knife assembly 4 is used to place the drawn plastic film and the lamination table 5 for placing the packaging board to be coated on the plastic film, and is used to attach the wide part around the packaging board to be coated to the packaging The edge brushing mechanism 6 on the side of the board; figure 1 The two sides of the shown front and rear direction) are respectively provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com