Molding press for rubber-surface plastic shoes

A compression molding machine and plastic technology, applied in applications, household components, household appliances, etc., can solve the problems of waste of manpower and energy, damage to plastic shoes, waste of production raw materials, etc., to save time for installation and replacement, and to achieve uniform molding depth , Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

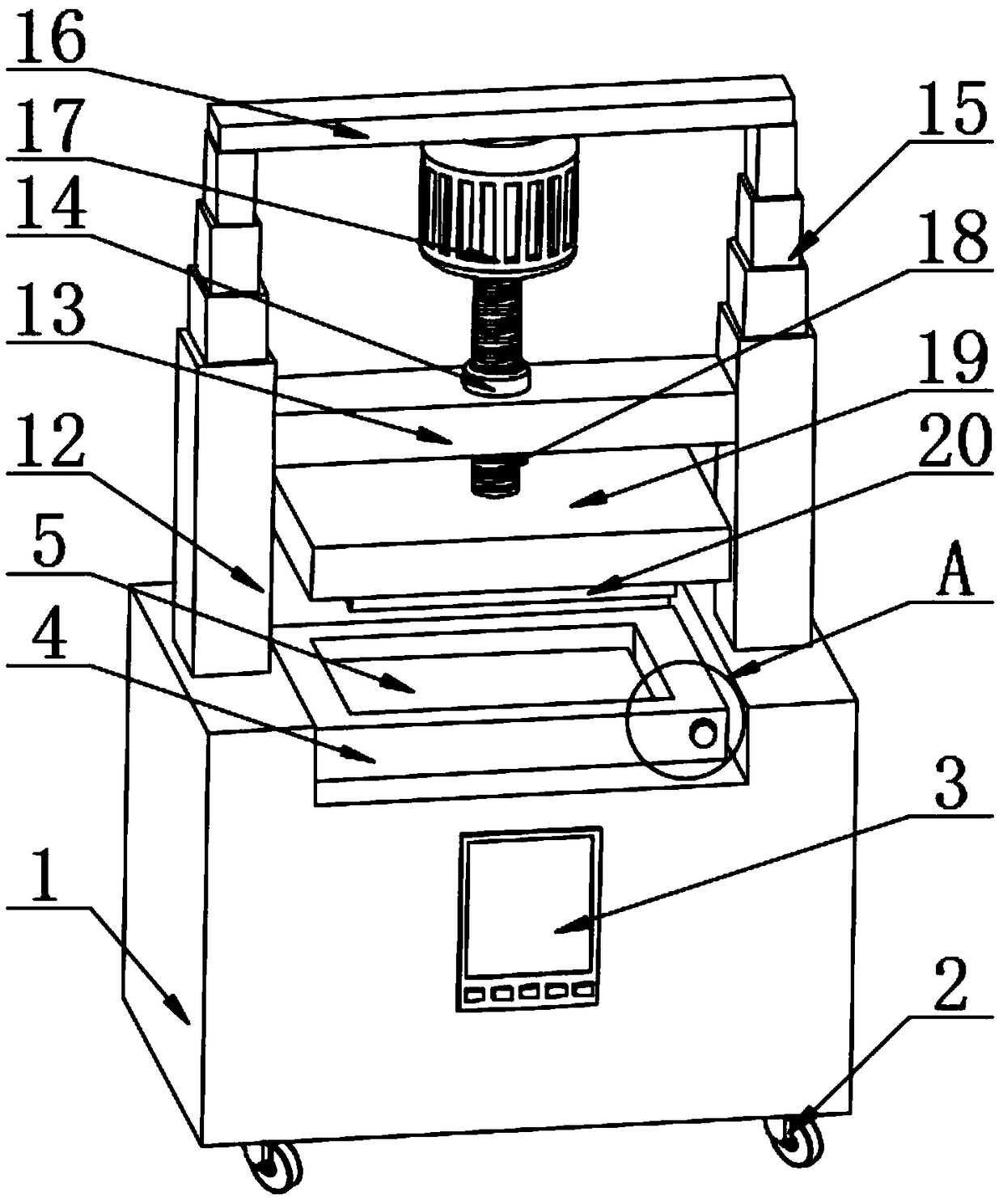

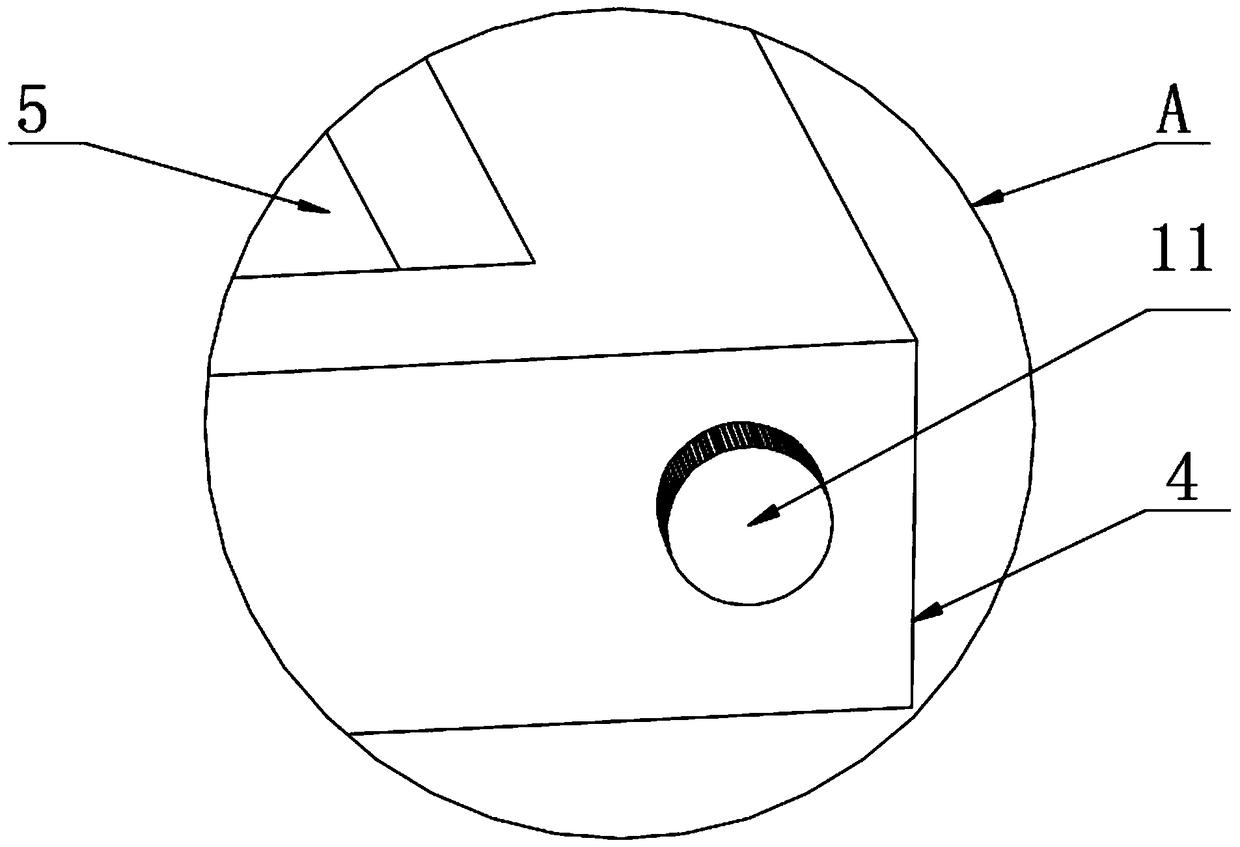

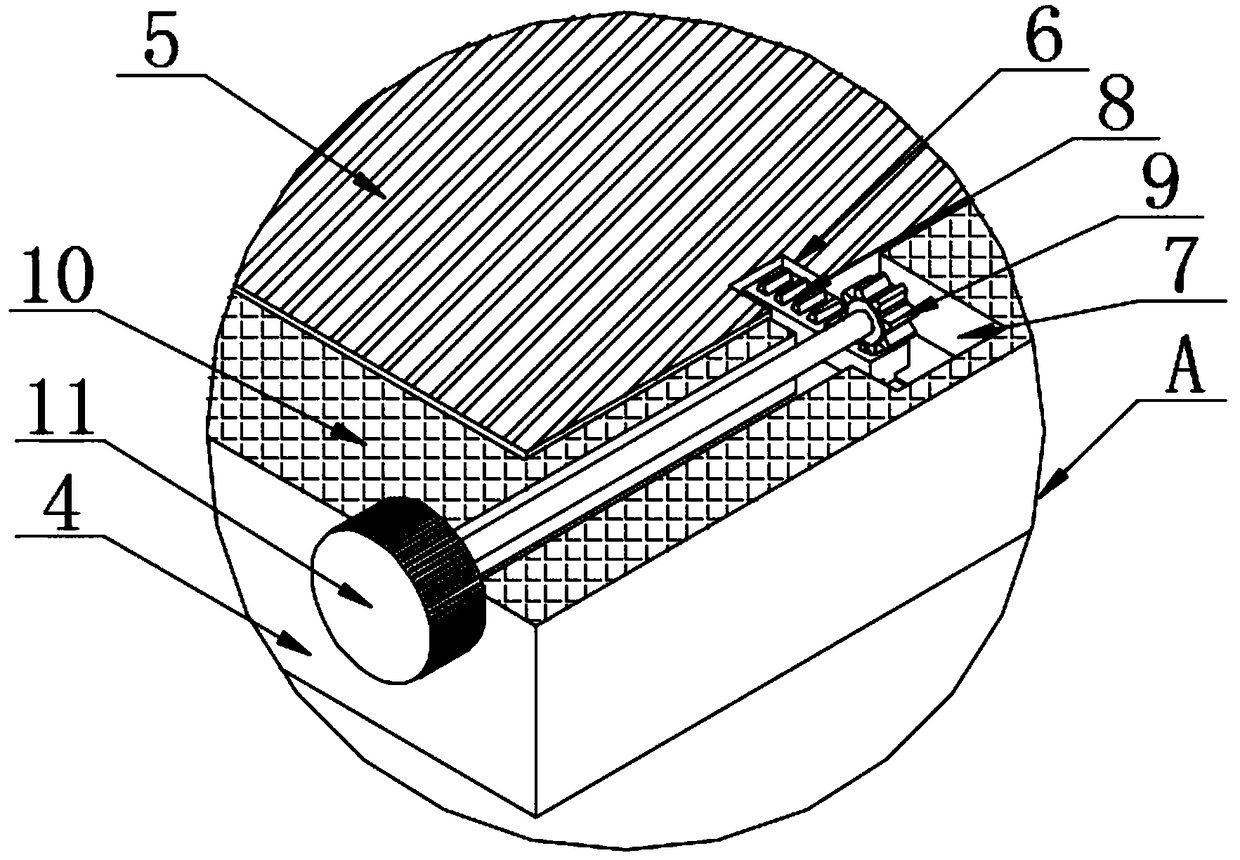

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, including a box body 1, a roller 2, a control button 3, a fixed frame 4, a lower template 5, a limit hole 6, an installation groove 7, a limit rod 8, an adjustment gear 9, a connection Rod 10, adjusting knob 11, mounting frame 12, fixing rod 13, fixing nut 14, telescopic rod 15, fixing frame 16, motor 17, lead screw 18, mounting plate 19 and upper module 20, the four corners of the bottom of the box body 1 correspond to The roller 2 is fixedly installed. In order to facilitate the handling and fixing of the molding machine, the roller 2 is a self-locking universal roller member. A control button 3 is embedded in one side of the box body 1, and the top of the box body 1 is fixedly installed. There is a fixed frame 4, the inside of the fixed frame 4 is provided with a lower template 5, one side of the lower template 5 is provided with a limit hole 6, and one side of the fixed frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com