Locking type vegetable cutting device

A vegetable cutting device and locking technology, which is applied in metal processing and other directions, can solve the problems of low cutting efficiency of the cutting device, inflexible adjustment of the position of the cutting blade, and inability to adjust the position of the cutting blade, etc., achieving ingenious structural design, flexible use, and good performance. Effect of cutting status and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

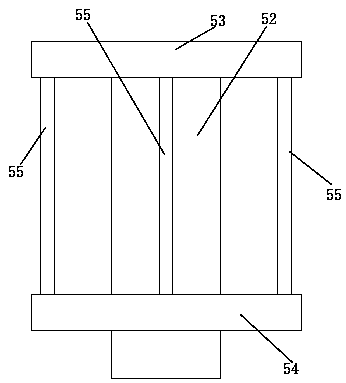

[0023] Such as Figures 1 to 6 As shown, a locking vegetable cutting device includes a base 1, a cutting bin 2, a feeding bin 3, a cutting mechanism 5, and a locking mechanism 6; the cutting bin 2 is installed on the upper end of the base 1; the feeding bin 3 is installed on the upper end of the cutting bin 2; the feeding bin 3 communicates with the cutting bin 2; the feeding bin 3 is in a ring structure, which is conducive to dispersing vegetables and cutting more evenly; the cutting mechanism 5 is installed on the cutting Inside warehouse 2. Such as figure 1 and 2 As shown, the cutting mechanism 5 includes a drive motor 51 , a drive shaft 52 , an upper baffle 53 , a lower baffle 54 , a lead screw 55 , a sliding block 56 , a locking nut 57 , and a cutting blade 59 . The driving motor 51 controls the rotation of the driving shaft 52; the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com