Correcting device for wire breaker

A technology of wire holes and copper wires, which is applied in the field of correction devices for wire breakers, can solve problems affecting the use of copper wires, untreated dust, and affecting the quality of finished inductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

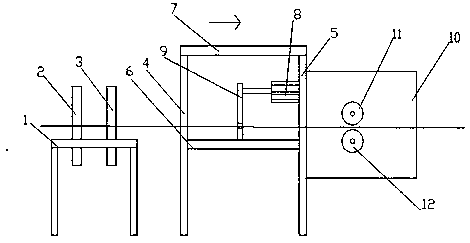

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0019] Such as Figure 1-3 As shown, the technical solution of the present invention is: a straightening device for a wire breaking machine, including a traction mechanism, a first leveling mechanism and a second leveling mechanism arranged in sequence along the copper wire transmission direction;

[0020] The traction mechanism includes a traction platform 1, and the traction platform 1 is respectively provided with a first traction circle 2 and a second traction circle 3, and the first traction circle 2 and the second traction circle 3 are left and right parallel Setting, after the copper wire is drawn out from the coil frame, it is transmitted along the first traction circle 2 and the second traction circle 3 in sequence;

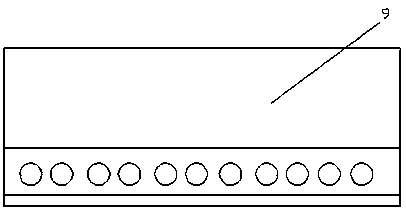

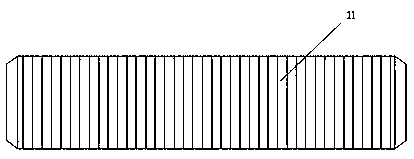

[0021] The first leveling mechanism includes a leveling left plate 4 and a leveling right plate 5, the middle and upper end bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com