Vertical rotary chemical reagent mixing device

A technology of chemical reagents and mixing devices, which is applied to mixers with rotating containers, mixers, chemical instruments and methods, etc., can solve the problems of unsatisfactory effects, low efficiency of manual stirring or shaking, etc., to reduce the amount of manual labor, Good mixing effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

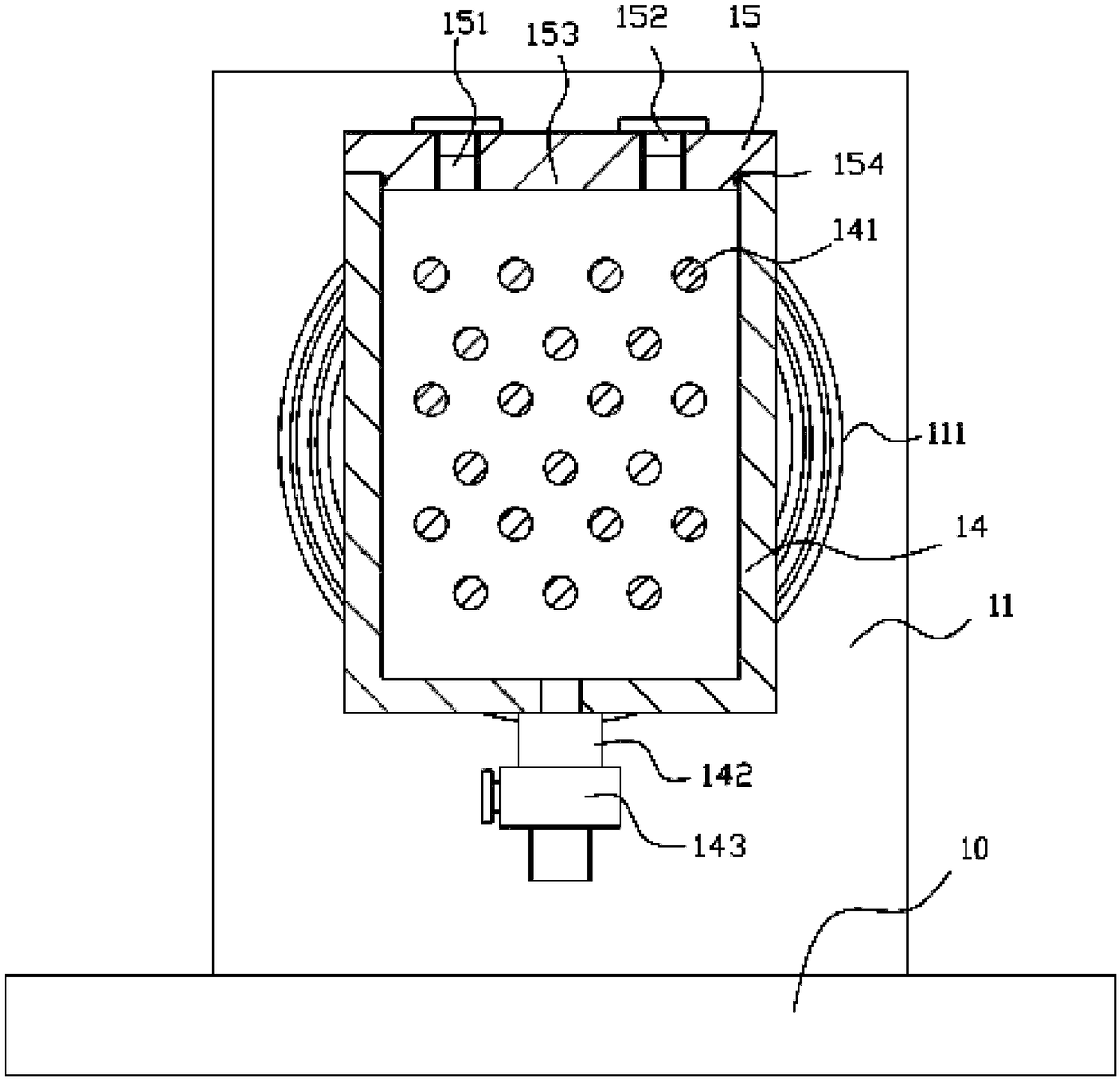

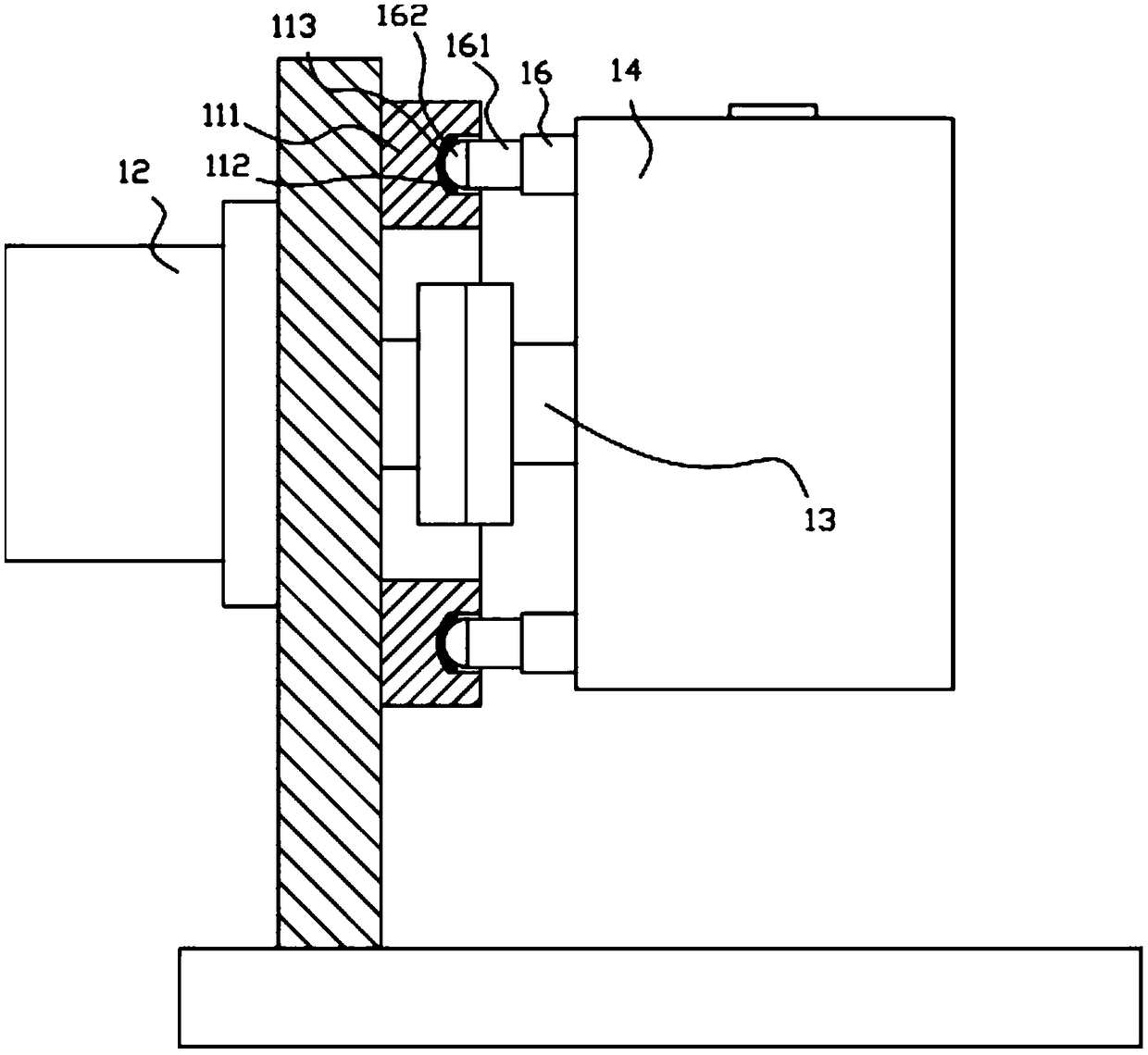

[0017] Example: see Figure 1 to Figure 2 As shown, a vertical rotary chemical reagent mixing device includes a fixed bottom plate 10, the rear portion of the top surface of the fixed bottom plate 10 is fixed with a main vertical plate 11, and the middle part of the rear wall surface of the main vertical plate 11 is fixed with a Rotating servo motor 12, the output shaft of rotating servo motor 12 passes through main vertical plate 11 and is connected with rotating shaft 13 by coupling, the front end of rotating shaft 13 is fixed with mixing tank body 14, and the top of mixing tank body 14 is fixed with The cover body 15 has a plurality of feeding screw holes 151 formed on the top plate of the cover body 15;

[0018] The top of the feeding screw through hole 151 is screwed with a plug 152;

[0019] The interior of the mixing tank 14 is provided with a plurality of stirring cylinders 141, and the two ends of the stirring cylinders 141 are fixed on the inner sidewall of the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com