Agaricus subrufescens noodles and preparation process thereof

A preparation process, technology of Agaricus blazei, applied in the direction of food ingredients as taste improver, function of food ingredients, food science, etc., can solve problems such as incomplete nutritional ingredients, unreasonable amino acid composition, single composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

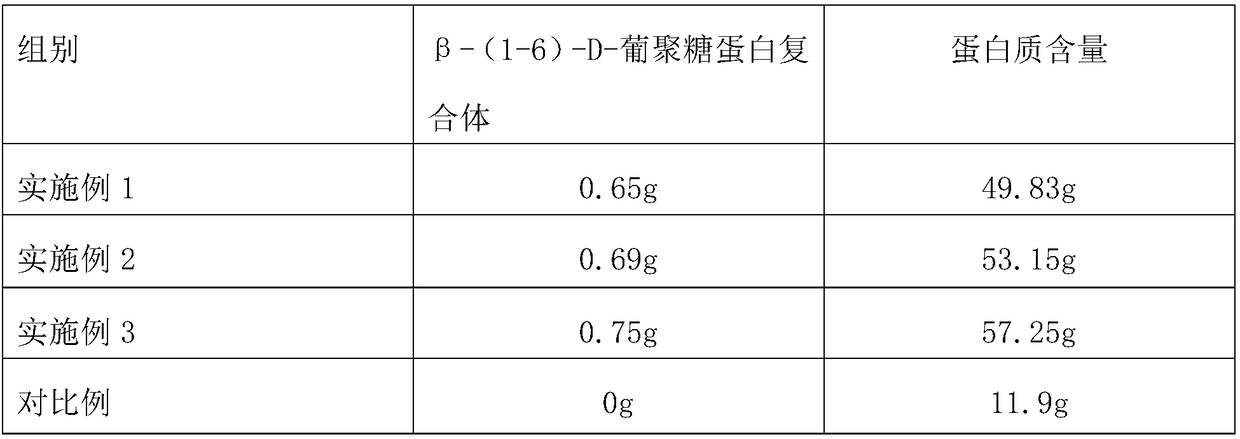

Examples

Embodiment 1

[0023] Embodiment 1: A kind of Agaricus blazei noodles, raw material comprises the following components by weight: 70 parts of wheat flour, 8 parts of Agaricus blazei powder, 0.3 part of peanut oil, 0.5 part of sodium carbonate, 0.2 part of sodium chloride, 10 parts of water , 0.1 part of sucrose.

[0024] A kind of preparation technology of Agaricus blazei noodles, comprises the following steps:

[0025] Step 1. Raw material pretreatment: After screening and removing impurities, the dried Agaricus blazei is cleaned with water, then dried in a blast drying oven at 45°C, crushed to 150 mesh, and then used for later use;

[0026] Step 2. Mixing: According to the above weight parts, add wheat flour, Agaricus blazei powder, peanut oil, and sodium carbonate into a closed stirring device for mixing. The stirring time is 5 minutes. After standing for 5 minutes, add Stir after water for 30min to get the dough;

[0027] Step 3. Noodle preparation: use a single-screw extruder to feed ...

Embodiment 2

[0029] Embodiment 2: a kind of Agaricus blazei noodles, raw material comprises the following components by weight: 72.5 parts of wheat flour, 9.5 parts of Agaricus blazei powder, 0.5 part of peanut oil, 0.75 part of sodium carbonate, 0.25 part of sodium chloride, 11 parts of water , 0.2 parts of sucrose.

[0030] A kind of preparation technology of Agaricus blazei noodles, comprises the following steps:

[0031] Step 1. Raw material pretreatment: After screening and removing impurities, the dried Agaricus blazei is cleaned with water, then dried in a blast drying oven at 45°C, crushed to 170 mesh, and then used for later use;

[0032] Step 2. Mixing: According to the above weight parts, add wheat flour, Agaricus blazei powder, peanut oil, and sodium carbonate into a closed stirring device for mixing. The stirring time is 6 minutes. After standing for 5 minutes, add Stir after water for 35 minutes to get the dough;

[0033] Step 3. Noodle preparation: use a single-screw extru...

Embodiment 3

[0035] Embodiment 3: a kind of Agaricus blazei noodles, the raw material comprises the following components by weight parts: 75 parts of wheat flour, 11 parts of Agaricus blazei powder, 0.7 part of peanut oil, 1 part of sodium carbonate, 0.3 part of sodium chloride, 12 parts of water , 0.3 parts of sucrose.

[0036] A kind of preparation technology of Agaricus blazei noodles, comprises the following steps:

[0037] Step 1. Raw material pretreatment: After screening and removing impurities, the dried Agaricus blazei is cleaned with water, then dried in a blast drying oven at 45°C, crushed to 200 meshes, and then used for later use;

[0038]Step 2. Mixing: According to the above weight parts, add wheat flour, Agaricus blazei powder, peanut oil, and sodium carbonate into a closed stirring device for mixing. The stirring time is 7 minutes. After standing for 5 minutes, add Stir after water for 40min to get the dough;

[0039] Step 3. Noodle preparation: use a single-screw extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com