A lithium ion battery wide temperature electrolyte

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor cycle performance, solidification, and limited application of conductivity, so as to improve low-temperature performance and safety performance, reduce Viscosity, freezing point, and the effect of widening the temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

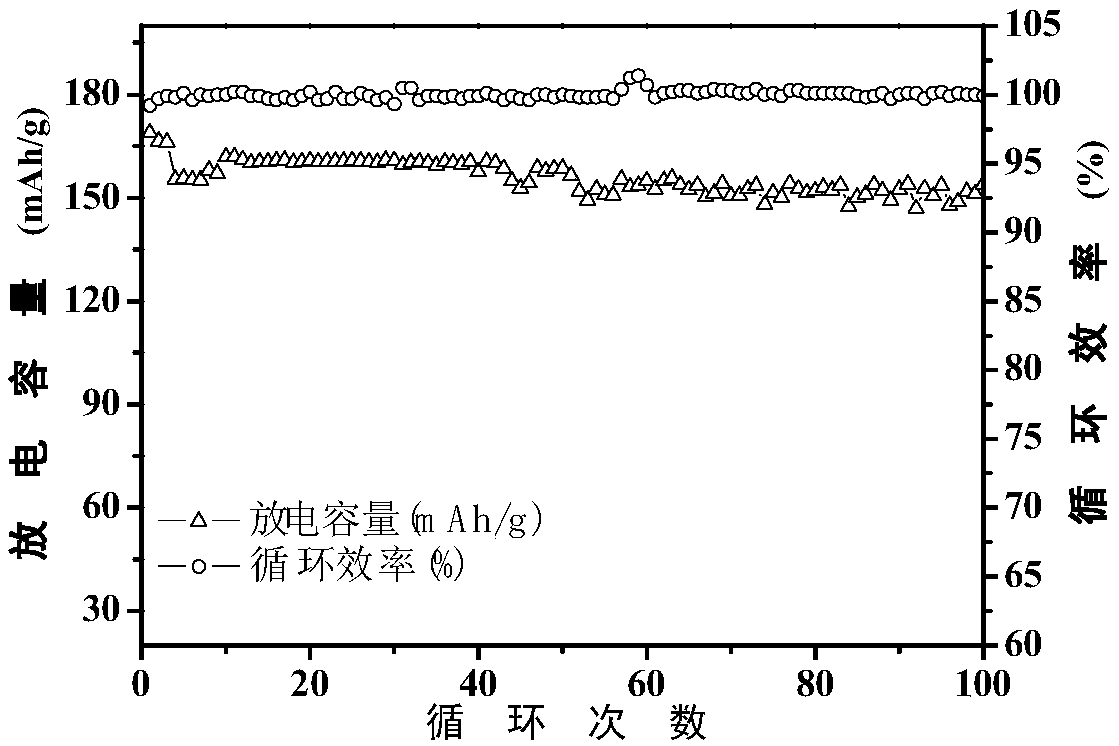

Embodiment 1

[0020] Electrolyte preparation: two solvents, triethylene glycol dimethyl ether (TEGME) and tetraethylene glycol dimethyl ether (TEGDE), were weighed and mixed in a mass ratio of 9:11, and stirred to form an electrolyte solvent; Add moles of LiTFSI into the electrolyte solvent, stir until fully mixed to form a homogeneous phase, and obtain an ionic liquid; add 1.5 parts by mass ratio of EMC to the ionic liquid and continue stirring until uniformly mixed; finally add 1% of the total mass of the electrolyte to the electrolyte % LiFSI is used as a low-temperature additive, and after it is fully dissolved, it is left for 10 hours to prepare a wide-temperature electrolyte for lithium-ion batteries.

[0021] Preparation of the negative electrode sheet: weigh the negative electrode material lithium titanate, the binder PVDF and the conductive agent Ketjen Black according to the mass ratio of 8:1:1, dissolve in NMP, and stir to form a slurry with a certain viscosity. Coat the slurry o...

Embodiment 2

[0025] The two solvents of TEGME and TEGDE were weighed and mixed according to a mass ratio of 7:13, and then stirred to form an electrolyte solvent; then equimolar LiTFSI was added to the electrolyte solvent, and stirred until fully mixed to form a homogeneous phase to obtain an ionic liquid; Add 1.5 parts by mass ratio of EMC to the liquid and continue to stir until it is evenly mixed; finally, add 1% LiFSI of the total mass of the electrolyte to the electrolyte as a low-temperature additive. electrolyte.

[0026] Battery production and testing are the same as in Example 1

Embodiment 3

[0028] The two solvents of TEGME and TEGDE were weighed and mixed according to the mass ratio of 5:15, and the electrolyte solvent was formed after stirring; then equimolar LiTFSI was added to the electrolyte solvent, and stirred until fully mixed to form a homogeneous phase to obtain an ionic liquid; Add 1.5 parts by mass ratio of EMC to the liquid and continue to stir until it is evenly mixed; finally, add 1% LiFSI of the total mass of the electrolyte to the electrolyte as a low-temperature additive. electrolyte.

[0029] Battery production and testing are the same as in Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com