Conical valve type automatic downhole blowout preventer and using method thereof

A blowout preventer and automatic technology, which is applied in the direction of wellbore/well valve device, earthwork drilling, flushing wellbore, etc., can solve the problem that the plug valve cannot withstand high pressure, etc., and achieve high degree of automation, fast speed and stability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

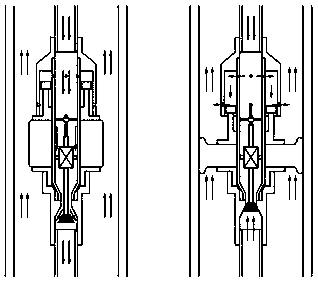

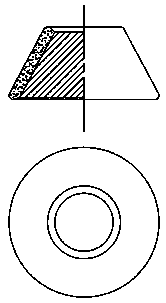

[0036] like figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of cone valve type automatic downhole blowout preventer device and using method, it is characterized in that: comprise upper drill pipe casing (1), inner pipe (2), drilling fluid inflow hole (3), annular piston (4 ), annular piston rod (5), drilling fluid outflow hole (6), guide ring fixing rod (7), rectangular guide ring (8), rectangular guide rod (9), lead screw (10), rubber tube (11) , motor fixing rod (12), linear motor system (13), rubber cartridge positioning ring (14), conical spool (15), lower drill pipe casing (16), drill pipe (17), wellbore (18) . The device is installed on the drill pipe (17), and the upper drill pipe casing (1) and the lower drill pipe casing (16) are connected with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com