Printed matter cutting device

A printing and cutting technology, which is applied in metal processing and other directions, can solve the problems of low cutting efficiency, the inability to adjust the cutting path of printed matter cutting equipment, and large differences in the final product size.

Inactive Publication Date: 2019-01-08

安徽瀚洋纸品印刷有限公司

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the problems in the prior art that there are large differences in the final product size of printed matter cutting, the printing matter cutting equipment cannot adjust the cutting path, and the cutting efficiency is low, the purpose of the present invention is to provide a printed matter cutting device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0027] It differs from Embodiment 1 in that the structure of the lifting device 11 is different. In this embodiment, the lifting device 11 includes a vertical rack mounted on the column 2, a lifting motor fixedly mounted on the mobile base 4 and a lifting motor mounted on the lifting frame 4. The gear on the motor is adapted to the vertical rack. During use, the lifting motor drives the mobile base 4 to slide up and down through gears.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

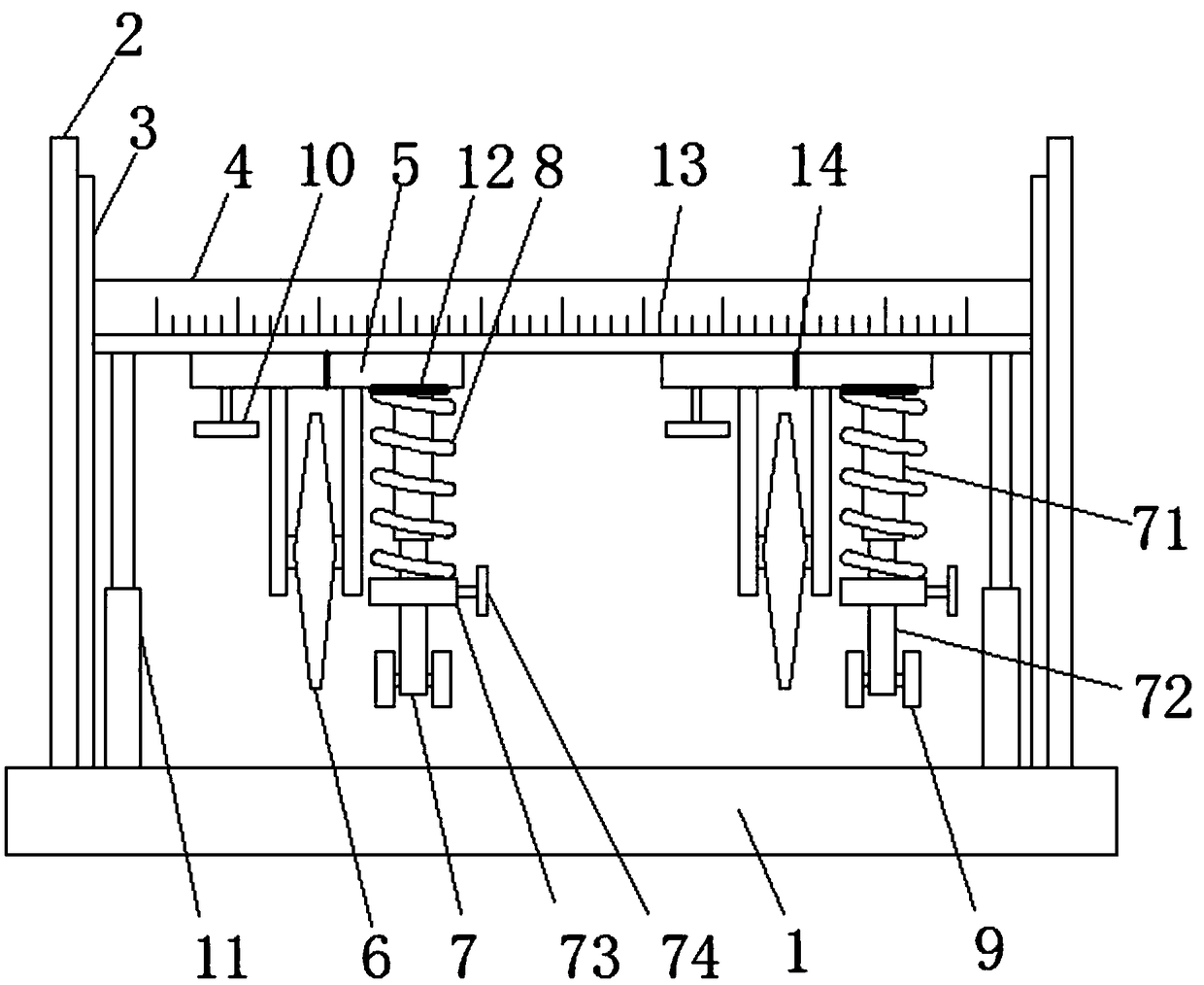

The invention discloses a printed matter cutting device, and belongs to printed matter cutting equipment. The printed matter cutting device comprises a fixed base and a movable base, the upper surfaceof the fixed base is provided with a stand column, the stand column is provided with a vertical slide rail, a vertical sliding block matched with the vertical sliding rail is arranged on the movablebase, a horizontal sliding rail is arranged on the lower surface of the movable base, a plurality of working tables are arranged on the horizontal sliding rails, a cutting knife and a paper fixing device are arranged on the surface of the working tables, the paper fixing device comprises a telescopic rod fixedly arranged on the surface of the working table, the telescopic rod is a sleeve type telescopic rod, the telescopic rod is sleeved with a reset spring, and the lower end of the telescopic rod is provided with an idler wheel; the working tables are provided with a first locking screw, andthe movable base is provided with a lifting device. According to the printed matter cutting device, the position error of the printed matter in the cutting process can be kept, and can also be adaptedto cutting of printed matters of various sizes and specifications, so that the cutting efficiency is improved.

Description

technical field [0001] The invention relates to the field of printed matter cutting equipment, in particular to a printed matter cutting device. Background technique [0002] Printed matter is a general term for various finished products produced by printing technology, including newspapers, books, notebooks, posters, etc. in daily life. The raw material of printed matter is paper, and most of them are standard paper with relatively large length. During the process of making printed matter, it needs to be cut according to the size of the final printed matter. [0003] Traditional paper cutting is mostly done manually, which not only has the problem of low cutting efficiency, but also has the problems of large differences in finished products and low standardization. [0004] At present, there are also machine cutting equipment for printed matter, but the existing cutting equipment also has the problem that the paper is not firmly fixed, which will cause a large error in the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B26D7/04B26D7/26B26D1/15

CPCB26D1/151B26D7/04B26D7/2635

Inventor 李晓梅

Owner 安徽瀚洋纸品印刷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com