Bending Beams for Rotary Bending Machines

A technology of bending beams and bending machines, applied in the field of bending beams, can solve the problems of limited availability of bending accuracy and achieve the effects of great flexibility, reliable angle measurement, and simplified positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] First of all, it should be ensured that in the differently described embodiments, the same parts have the same reference symbols or the same component designations, wherein the disclosure contained in the entire description can reasonably be transferred to the same reference symbols or the same component designations. of the same parts. Position specifications selected in the description, such as top, bottom, side, etc., also refer to the currently described and shown figures and can be transferred to the new position in the event of a position change.

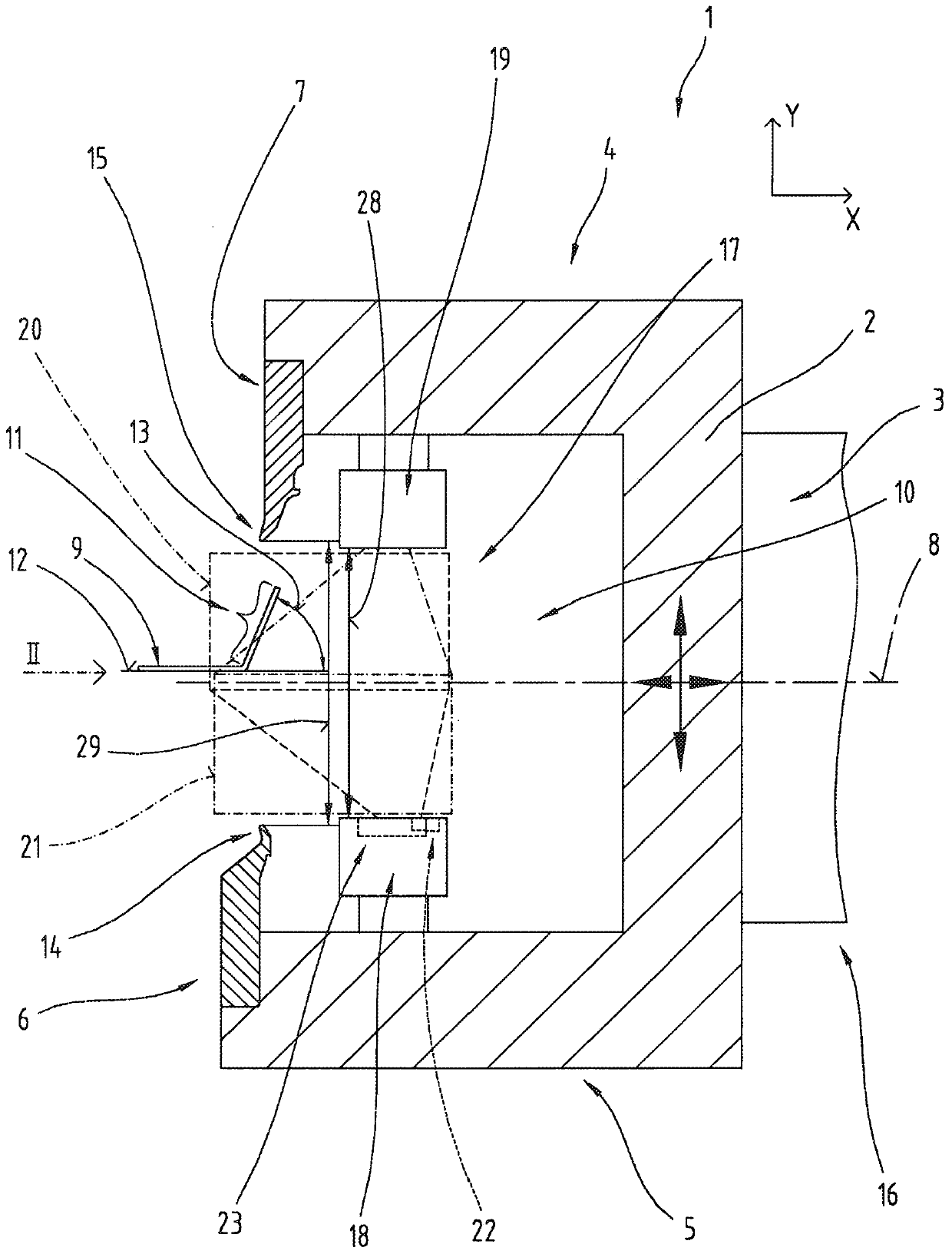

[0033] figure 1 A sectional view of a bending beam 1 of a rotary bending machine, not shown in detail, as known from the prior art is shown. The curved beam 1 is elongate perpendicular to the plane of the drawing and here has an approximately C-shaped beam cross-section 3 which essentially consists of a base 3 extending in an approximately vertical direction and two further It consists of sides 4 and 5 adjoining at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com