Pantograph-catenary pressure detection device

A detection device and distance measuring device technology, which is applied in the field of rail transit, can solve problems such as increased friction loss of the receiving grid, increased friction loss between the pantograph and the power supply network, and arcing between the pantograph and the power supply network, so as to improve the universality of the equipment. Good performance and environmental adaptability, avoid shortening the service life of equipment, and have strong data communication capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

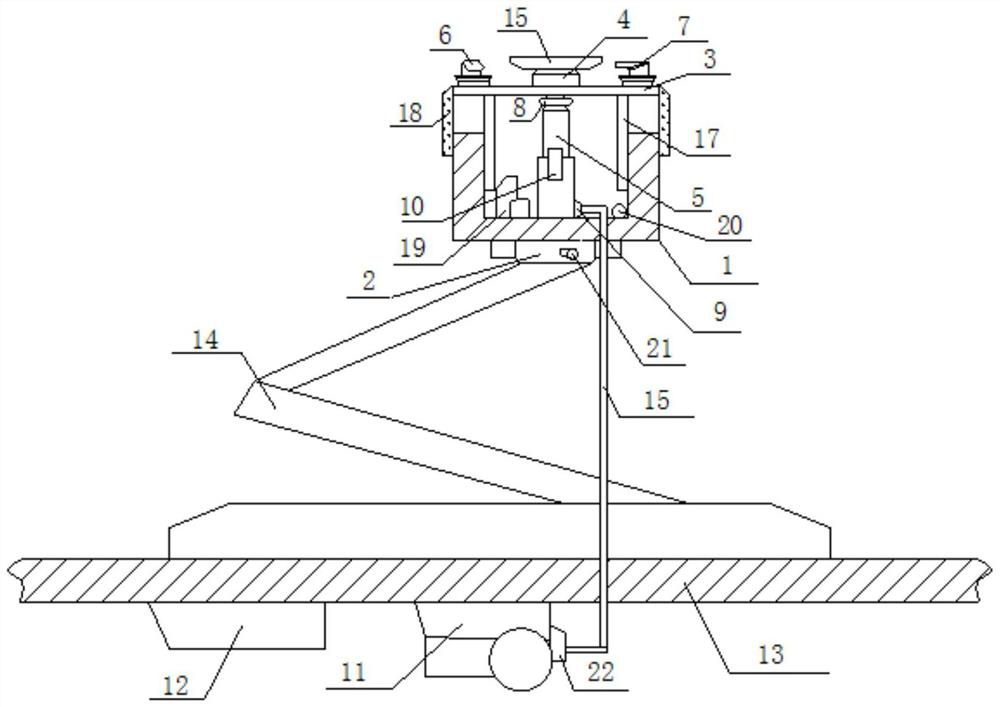

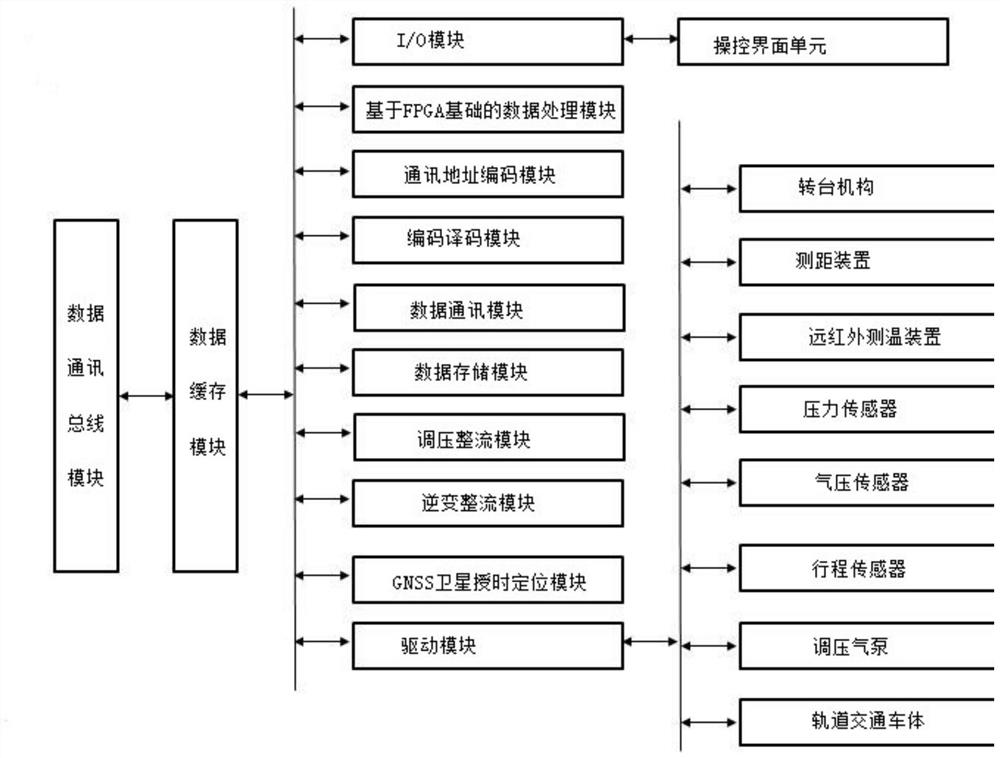

[0020] Such as figure 1 and 2 The pantograph-catenary pressure detection device includes a bearing base 1, a turntable mechanism 2, a workbench 3, a positioning mechanism 4, an air pressure telescopic rod 5, a distance measuring device 6, a far-infrared temperature measuring device 7, a pressure sensor 8, Air pressure sensor 9, stroke sensor 10, pressure regulating air pump 11 and control device 12, carrying base 1 is a groove-shaped structure with a cross section in the shape of "凵", and at least one turntable mechanism 2 is arranged on its lower end surface, and is installed on the carrying base. The outer surface of the bottom of the seat 1 is evenly distributed along the axis of the bearing base 1. The axis of the turntable mechanism 2 forms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com