Horizontal displacement monitor and its monitoring method

A technology of horizontal displacement and monitoring instrument, which is applied in the direction of instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of long field time, discontinuous monitoring data, and high cost of surveying and mapping, and achieve low requirements for observers, simple monitoring methods, Guarantee the effectiveness of monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

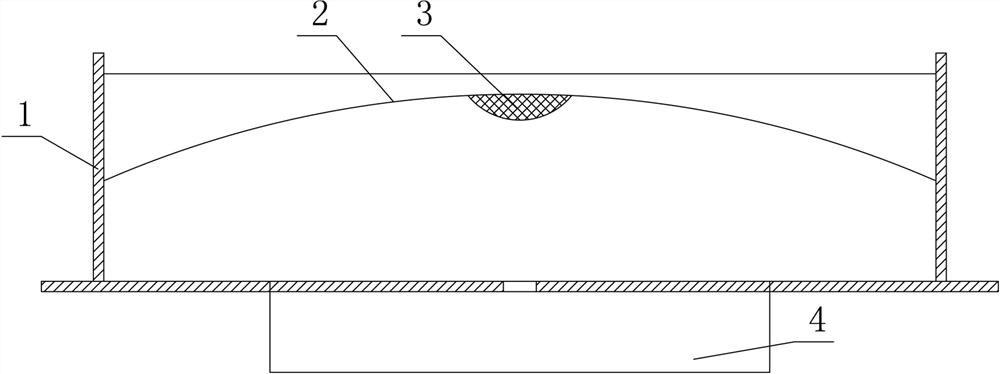

[0045] Such as figure 1 As shown, the horizontal displacement monitor includes a box body 1, a transparent latex cover 2 and the first adjusting device 4 for adjusting the spherical radius of the latex cover 2, and the top cover of the box body 1 is a transparent cover, such as a glass cover, To facilitate the observation of the test results, the edge of the latex cover 2 is sealed and fixed on the inner wall of the side plate of the box body 1, and the box body 1 is divided into an upper cavity and a lower cavity. The distance between the bottom plates of the body 1 is equal, the lower cavity is filled with liquid, and air bubbles are arranged in the lower cavity, and the latex cover 2 is provided with a scale 5 for displaying the horizontal displacement and / or the safety status of the monitored object.

[0046] In some embodiments, the side panels and the bottom panel of the box body 1 are made of hard materials such as steel, and the liquid is alcohol or ether.

[0047] Th...

Embodiment 2

[0055] The monitoring method of the horizontal displacement monitor includes:

[0056] S1. Install the horizontal displacement monitor on the object to be monitored so that the center of the ball corresponding to the latex cover 2 is on the same vertical line as the center of the circle when the object to be monitored tilts and rotates.

[0057] The specific installation method is: drill a hole on the monitored object, insert one end of the fixed rod into the monitored object, and insert the other end into the fixed hole 12, and the fixed rod and the fixed hole 12 are connected by threads.

[0058] S2. Adjust the spherical radius of the latex cover 2 to make it equal to the vertical distance between the horizontal displacement monitor 2 and the center of circle when the monitored object tilts and rotates.

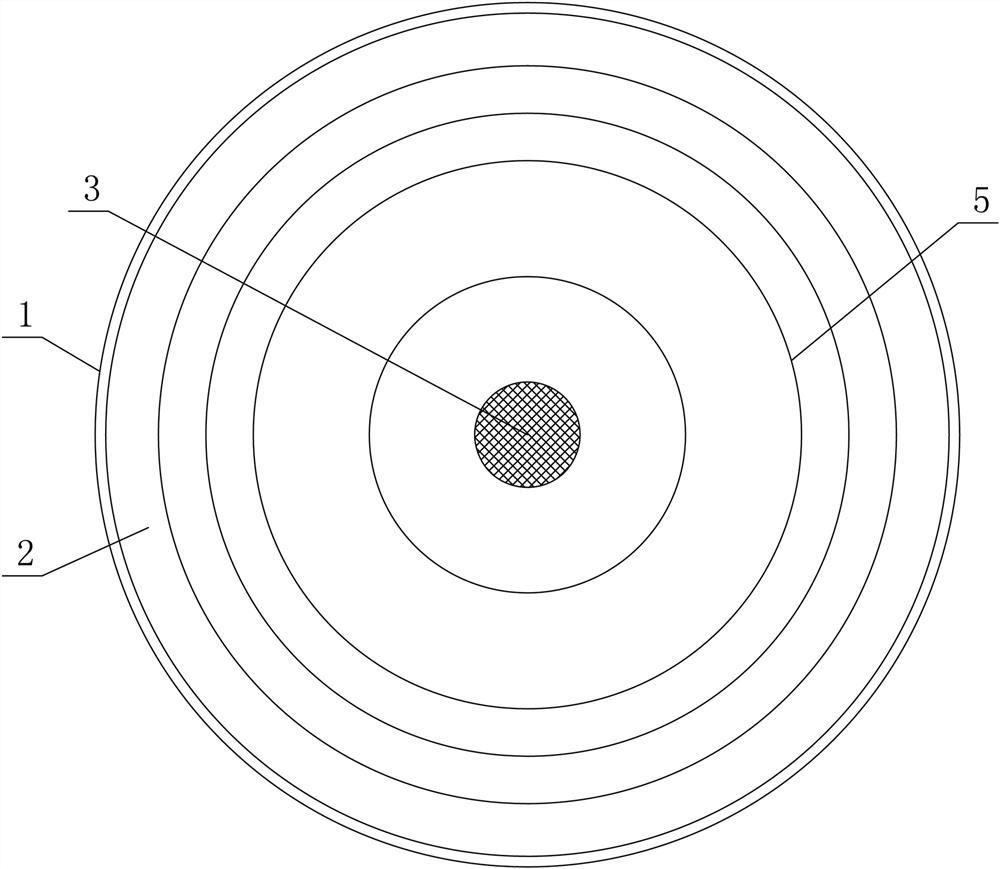

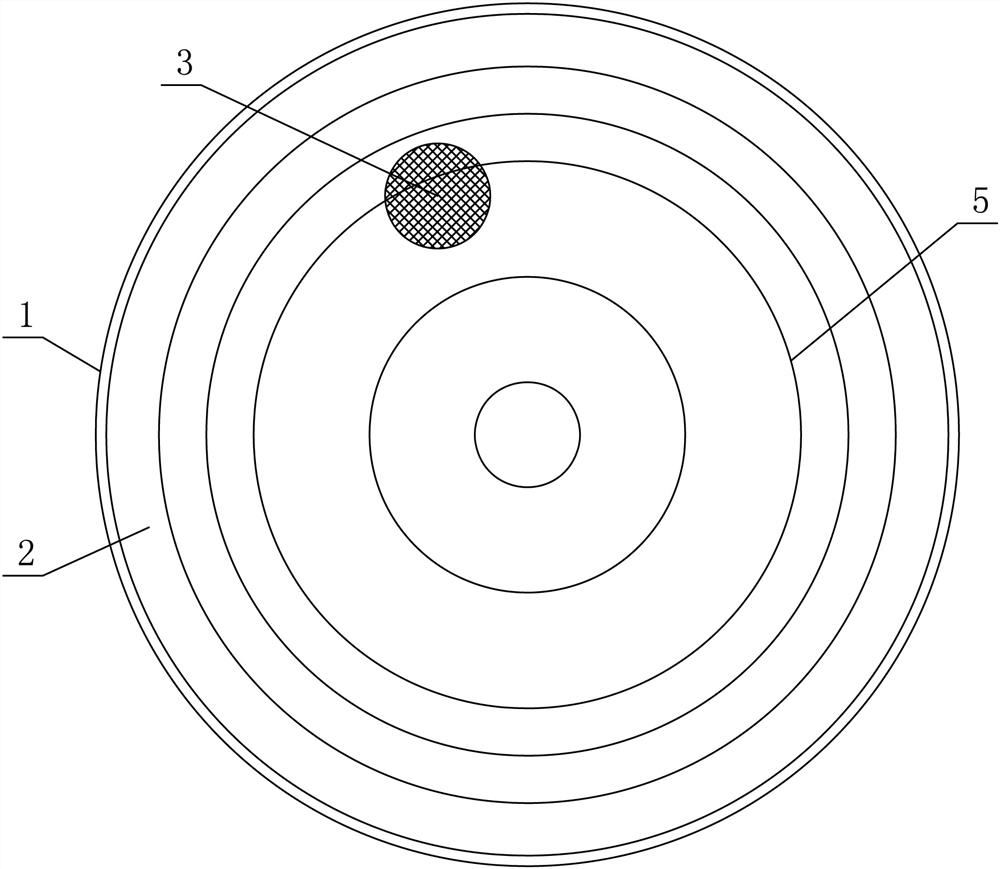

[0059] S3. Read the scale 5 corresponding to the bubble 3, and obtain the horizontal displacement value according to the scale 5 corresponding to the initial moment of the ...

Embodiment 3

[0062] The monitoring method of the horizontal displacement monitor includes:

[0063] A1. Install the horizontal displacement monitor on the object to be monitored so that the center of the ball corresponding to the latex cover 2 is on the same vertical line as the center of the circle when the object to be monitored tilts and rotates.

[0064] A2. Adjust the horizontal displacement monitor so that the bubble 3 is at the center of the latex cover 2 at the initial moment.

[0065] A3. Adjust the spherical radius of the latex cover 2 to make it equal to the vertical distance between the horizontal displacement monitor 2 and the center of circle when the monitored object tilts and rotates.

[0066] A4. Read the scale 5 corresponding to the bubble 3 to obtain the horizontal displacement value and / or the safety status of the monitored object. That is to judge the positional relationship between the bubble and the warning line, warning line and alarm line, so as to obtain the safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com